![]()

1

The Leadership Challenge

Whether it is a Pentium chip from Intel or a birdhouse with a “Spanish tile roof” from Rubbermaid, the successful new product both satisfies and delights customers. It conforms to an increasingly broad range of customer expectations about quality and design as well as delivery and service performance; at the same time, it introduces something different—a new dimension of functionality, a new feature, something unanticipated in the “package of benefits” provided. For companies such as Intel and Rubbermaid, in industries as seemingly disparate as state-of-the-art ICs and mundane plastic household goods, new product development is at the heart of their business.

But one successful new product does not build a successful, enduring enterprise. In today’s savage competitive environment, enduring success requires consistent excellence in developing new products. The one-shot successful deal is just that—it leads nowhere and its impact on the bottom line is fleeting in a world where the demand for new products is relentless.

Much has been done in recent years to create new methods and frameworks for making product development faster, more efficient, and more effective. Outstanding firms such as Intel and Rubbermaid have adapted a host of these new tools and techniques and felt their impact. But putting new product development at the heart of the business and achieving consistent excellence in the development of new products is not just a matter of the right tools and techniques or the latest methods and frameworks, powerful as they may be. What counts here—and what is so often hidden and undervalued—is the leadership of senior management.

Senior managers have the benefit of a rare vantage point. They see the whole of the enterprise and its future, and thus they are in a unique position to understand the importance of product development to the success of the business. When senior managers lead, they recognize the power of product development and their role in it. They understand that:

• The consequences of product development have a direct impact on competitiveness. They mean the difference between falling behind a leading competitor in the marketplace and being the competitor who provides leadership, compelling others to meet similar standards.

• The bulk of a company’s assets are tied up in how it delivers value to its customers. If it has old products, the wrong products, or even the right products at the wrong time, that value is severely limited. If the firm “does” product development badly, its assets—particularly its equity with its customers—will wither and erode.

• The success or failure of product development is driven by the entire range of functions and activities—every dimension—of the organization. The development of a new product is the development of every aspect of the business that the product needs to be successful. And consistently successful new products need every aspect of the business working in harmony.

• Product development is the means by which a company builds capabilities. Through new product development, an organization creates the “energy”—the skills, processes, knowledge, and motivation—that drives its future. Put another way, these capabilities become the resource pool it draws from to meet future customer requirements. Thus, when product development becomes central to the business, it becomes a self-renewing well-spring of capabilities.

• Effective senior managers recognize that their most important contribution is their cumulative impact, rather than their influence on any single project. They act on the development process as a whole.

• Senior management touches everything the company does; what senior managers do sets the pattern and example for everyone in the business. Senior managers have a decisive influence on functional integration and the building of capability. Whether the business achieves integrated solutions in the short run and critical capacity for action in the long run depends on senior management leadership.

The Problem

Few senior managers would argue that new product development is unimportant; fewer still would imply that it is unrelated to “mainstream” business issues. However, the actions of many suggest that new product development is neither at the heart of their business nor central to their personal agenda. The critical issue is whether senior management leads product development so that developing new products is a primary focus of attention and commitment throughout the organization. The following kinds of comments are typical when product development is not a critical issue for senior management:

“Product development? We have a very talented product development group; their department is on the far side of the building. We’ve recently increased their budget, added some bright young people, and put in some new workstations. Product development is a priority here.”

“Product development? We’ve organized a senior management review committee that meets monthly to monitor progress on the projects under way. Our staff helps prepare the background for these meetings, and then we ask the tough questions. When the folks working on product development don’t have good answers, we send them back to the drawing board.”

“Product development? Well, our budget in that area is about 4% of revenues, and that’s better than most in our industry. Our chief technical officer manages the area and requests help from others as needed. So far, his group has done a great job of maintaining our image as an innovator.”

“Product development? We’ve got a lot of sophisticated, hot new products under way—they’re what our customers seem to want. Because these are highly technical and aimed at leading customers, we have our best people in R&D and marketing involved. My job is to help select projects and allocate resources, and then get out of the way. I believe firmly in delegation, lending support when it is requested and occasionally intervening if things get off track.”

“Product development? Well, as the chief operating officer, my principal focus is on day-to-day operations. But from time to time, a project does get my personal attention. Especially when it threatens our corporate performance. Then, I roll up my sleeves and really dig in. Decisions—hard decisions—have to be made, and only I can make them.”

On the surface, the senior managers behind these quotes are doing things to help product development. They are investing in new equipment, setting up processes to provide senior management input, employing their very best people, and empowering people to act. All are well intentioned, all are doing some things well, and all are involved in product development. But below the surface, there is something missing, and—in most cases—what is missing is very significant.

These senior managers have set limits on product development and delegated significant responsibility for its success. Product development is not at the heart of their agenda, and they do not lead. They may look at projects at a handful of key decision-making points, for example, when resources are required or when major milestones (or calendar dates) are reached. Senior managers at these points may step in to be a project’s patron saint, or at least a cheerleader. But this is not enough. Although many efforts in such businesses are conceived in a spirit of hopefulness and enthusiasm, all too many end up with insufficient resources, missed deadlines, inadequate performance, and burned out, disappointed project participants. Senior managers wind up fighting fires and trying to save the day at the eleventh hour. Simply put, good intentions and close involvement will not do the job.

Because product development is so difficult to do well, the plain fact is that it needs far more timely, comprehensive, coherent action by senior management. What makes development so hard is precisely what makes doing it well so rewarding:

• Product development touches everything the business does. By the time a new product reaches the market it will have passed through every function, to one degree or another, in the business. Put another way, as a firm develops a new project, it is basically simulating the entire business. It must think about how the product will be manufactured, what sourcing will be involved, what the supplier chain will look like, who will be involved in distribution, and how the new product will be promoted and serviced. Additionally, the firm must think about how customers and competitors will view and experience the product and, crucially, how it will fit into the product line.

• What matters exists in an uncertain future. Product development necessarily entails uncertainty—about competitors, about technology, about the organization’s ability to execute, and, most important, about customer acceptance of something that will arrive in the future. This last is the most vexing, for so often a product’s acceptance or rejection lies in the details and specifics. Say a business wants to introduce a new “anti-aging” face cream. It invests heavily in the chemical formulation it will put in the jar. But the customer’s experience is also determined by all sorts of details about the product’s packaging, fragrance, aesthetics, feel, and color, its consistency and quality in production, how it is sold and where, and above all, how it is advertised. All of these details must work together as a total system. And all this has to be anticipated and addressed anywhere from several months to several years in advance.

Coping with complexity and uncertainty in an individual project is hard enough. Here the challenge is to achieve excellence in product development consistently This calls for senior managers who can see the business as a whole, clarify what needs to be done, and pull the organization together to make it happen. Unfortunately, the pressures senior managers confront and their own instincts often get in the way of effective action. Thus, not only is product development flat out hard to begin with, but natural tendencies in senior management make it even harder.

• The pressure is on to respond to competitors—immediately. Pressure can come from many sources within the organization. When driven by senior managers, its consequences by and large are more immediate—and pervasive. Consider, for example, a senior manager who visits a major customer. During the conversation, the customer asks, “Why don’t you have a purple square one? We get our purple square ones from Company X, your competitor. If you had one, we’d buy yours.” This is brand-new information to the senior manager, who returns to the office, hauls in the development folks, pounds the table, and demands: “Why don’t we have a purple square one?” Sure enough, pretty soon a project to develop a purple square one is under way.

Perhaps the senior manager also visits a key supplier, who notes, “We’re on this project to incorporate a new material—of course it’s for one of your competitors, but boy, this stuff is terrific.” Back at the office, the development folks are ordered, “We’ve got to make use of this new material. We’ve got to get that technology; it’s where the competition is going.” That project, too, enters the pipeline, and the result is a hodgepodge of efforts under development.

• The illusion of activity. This problem exacerbates all the others. Senior managers want to ensure that people are productive, that action is being taken, that things are happening. This can be summed up as “more is more.” Thus, in the absence of a sufficiently comprehensive and strategic process for evaluating what should become a project and why, the bias is to keep on adding projects—both to ensure that “things happen” and to demonstrate responsiveness to customers’ wishes and competitors’ threats. When there is activity, the organization looks productive. The illusion of activity, however, is deadly. It leads to scattershot efforts, badly focused resource allocation, and overloading of resources. Everything in the pipeline is jeopardized. In the end, “more is less.”

• Projects are where the action is. In companies without strong connections between business strategy and development projects, projects become places where important issues are resolved. To keep the business on the right course, senior managers feel compelled to make key decisions. But they often slow a project down or come into it late, when the project has veered off track. The result is heroic firefighting—something senior managers often enjoy and at which they excel. But although such activity does put out fires, it does not build capability or deliver distinctive value to the marketplace.

All of these problems are evident in the tale of Global Electronics, a disguised case history that reflects an all too common reality.

Global Electronics’ Compact Disc Project

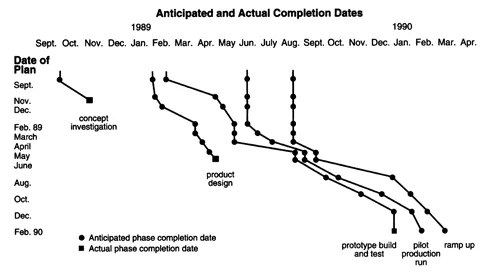

The marketing group of the personal stereo systems unit at Global Electronics, a large international consumer electronics company, was concerned that a key competitor was working on a new portable compact disc system and that Global would have to respond quickly to meet this challenge. The personal systems product manager presented a concept development plan to the head of marketing for a new, competitive system that would be more sophisticated and make use of better technology. The plan indicated a project development cycle time of one year, running from September to September, thereby allowing volume production to meet expected Christmas demand (see the initial row of Figure 1-1 for the original time line). With the strong support of marketing, senior management signed off on the concept development plan for the product (code-named Falcon), and prospects looked bright.

Things began to go wrong from the outset and only got worse. First, the concept development stage was completed six weeks late because of significant disagreements about what features Falcon should have and where it should fit in the product line; no change was made to the commercial introduction schedule to reflect this early delay (see Figure 1-1 for the updated time line). Furthermore, eight weeks were added to the prototype build and test schedule because the engineering group decided to use a new signal processing chip and identified several additional technical challenges during the concept development stage.

Figure 1-1

The Falcon Time Line

Not long after concept development, other problems with design deadlines emerged (there was limited capacity in the drafting department), and the design completion and prototype/test schedules were revised; however, no revision was made to pilot or ramp-up schedules because everyone agreed that pre-Christmas introduction was essential. Meanwhile, even though the design was not finished, process engineering and manufacturing groups began work on the manufacturing process.

A month after the revised deadline for design completion passed, design engineers were still hard at work, wrestling with a new set of problems related to product weight and cost. Concerns about weight had surfaced in market research, and new targets had been set following the introduction of Global’s XR22, a midrange product, just a few months earlier. Marketing felt that Falcon had to be priced only $50 above the XR22 to fit in the product line. At the same time, new prototype and production process difficulties emerged. Two key product engineers had been pulled off Falcon to handle a crisis during the launch of the XR22 (the disc changer mechanism was damaging the CDs), and work on the Falcon prototypes was essentially put on hold for the three weeks they were gone. For its part, process engineering was grappling with delays in tooling as it received a steady stream of engineering change orders to deal with modifications to Falcon’s cost and performance. Prototype completion was rescheduled for August and pilot production and ramp up would swiftly follow: the final September date was still in effect, in part because no one working 80-hour weeks on the project wanted to be the messenger who brought such a significant date change—one that meant missing the Christmas market—to senior management.

More problems subsequently appeared, primarily because the product design and the new automated assembly equipment did not work together successfully. The equipment had been specified and installed by manufacturing to meet cost targets and reduce variable costs, but it needed extensive debugging and some of its characteristics conflicted with those of the product design. These problems only surfaced at the prototyping phase, however. As a result, the original project deadline was missed, along with the Christmas season. Prototype testing was finally completed the following February.

At this point, the product’s “aesthetics” were deemed out of date (competitors had introduced new products); in response, marketing pushed through a redesign of the packaging, which meant that engineering needed a crash program entailing new tooling and testing. The redesigned product finally went into production in late summer. Meanwhile, manufacturing was debugging the redesigned assembly equipment (to deal with the packaging redesign) and testing for quality. In September, one year later than planned, volume production geared up to meet that year’s Christmas season. Demand, while adequate, hardly matched original expectations; worse, design engineering and manufacturing soon faced quality problems from the field (the new manufacturing process and the design were not as complementary as planned), and these led to more engineering change orders, particularly to improve manufacturability. As a consequence, design engineering launched yet another crash program to improve quality and reliability.

Looking back, the Falcon was a challenging project, but the complexity and uncertainty it faced differed little from that of scores of projects Global had completed over the years. In fact, the Falcon experience was not atypical. Veterans at Global could recount story after story about projects that met a similar fate. Behind much of the history of poor performance (and behind the poor performance of Falcon) lay the attitudes and behavior of senior management. Believing that more is more, they had loaded a project into an overstressed organization, failed at the outset to connect it fully to the business strategy or even to other products in the line, did not give it the resources it needed, failed to recognize the need for new skills, added even shorter time requirements, and changed direction midstream in response to competitors’ moves. While each of these factors could have been handled individually, collectively they spelled pain and disappointment.

Of course, there were many other problems behind the design changes, tooling delays, prototyping errors, and mismatch between the design and the manufacturing process. But of all the problems Falcon confronted, its basic difficulty was that the various pieces of the project puzzle—from the project’s intent to its execution—were never considered as a whole and effectively integrated. When considered in isolation, the idea behind the Falcon—to confr...