eBook - ePub

The Purchasing Machine

How the Top Ten Companies Use Best Practices to Manage Their Supply Chains

- 352 pages

- English

- ePUB (mobile friendly)

- Available on iOS & Android

eBook - ePub

The Purchasing Machine

How the Top Ten Companies Use Best Practices to Manage Their Supply Chains

About this book

Every day companies leave billions of dollars in invisible, unrealized savings on the table because of poor supply chain management practices. Now supply management experts Dave Nelson, Patricia E. Moody, and Jonathan Stegner show not only how leading companies recoup these savings through their mastery of target costing, value engineering, and supplier development, but how supply chain management -- the discipline of acquiring and moving material -- has become a manufacturing company's hottest competitive weapon.

Based on a survey of 247 purchasing managers and more than 1,000 hours of interviews and on-site visits, the authors have selected ten top firms whose supply management pioneers excel at twenty "best practices." With cases and stories, Nelson, Moody, and Stegner show how these leading-edge purchasing departments at American Express, SmithKline Beecham, DaimlerChrysler, Harley-Davidson, Honda of America, IBM, John Deere, Whirlpool, Flextronics, and Sun Microsystems have put into place pathbreaking processes and procedures. Here, for example, described in step-by-step detail, are Chrysler's SCORE program and Honda's strategic sourcing strategy that saved the companies billions. The book also includes a crucial section on the next stage of supplier development that will involve the sourcing and allocation of ideas as well as materials.

The authors provide concrete, practical steps to improvement that any supply chain manager can take to successfully implement these best practices. The Purchasing Machine will be required reading for logistics, purchasing, and procurement managers in hundreds of thousands of companies. The authoritative nature of the authors' source material is certain to make this the single most important and practical reference on best purchasing practices for years to come.

Based on a survey of 247 purchasing managers and more than 1,000 hours of interviews and on-site visits, the authors have selected ten top firms whose supply management pioneers excel at twenty "best practices." With cases and stories, Nelson, Moody, and Stegner show how these leading-edge purchasing departments at American Express, SmithKline Beecham, DaimlerChrysler, Harley-Davidson, Honda of America, IBM, John Deere, Whirlpool, Flextronics, and Sun Microsystems have put into place pathbreaking processes and procedures. Here, for example, described in step-by-step detail, are Chrysler's SCORE program and Honda's strategic sourcing strategy that saved the companies billions. The book also includes a crucial section on the next stage of supplier development that will involve the sourcing and allocation of ideas as well as materials.

The authors provide concrete, practical steps to improvement that any supply chain manager can take to successfully implement these best practices. The Purchasing Machine will be required reading for logistics, purchasing, and procurement managers in hundreds of thousands of companies. The authoritative nature of the authors' source material is certain to make this the single most important and practical reference on best purchasing practices for years to come.

Frequently asked questions

Yes, you can cancel anytime from the Subscription tab in your account settings on the Perlego website. Your subscription will stay active until the end of your current billing period. Learn how to cancel your subscription.

No, books cannot be downloaded as external files, such as PDFs, for use outside of Perlego. However, you can download books within the Perlego app for offline reading on mobile or tablet. Learn more here.

Perlego offers two plans: Essential and Complete

- Essential is ideal for learners and professionals who enjoy exploring a wide range of subjects. Access the Essential Library with 800,000+ trusted titles and best-sellers across business, personal growth, and the humanities. Includes unlimited reading time and Standard Read Aloud voice.

- Complete: Perfect for advanced learners and researchers needing full, unrestricted access. Unlock 1.4M+ books across hundreds of subjects, including academic and specialized titles. The Complete Plan also includes advanced features like Premium Read Aloud and Research Assistant.

We are an online textbook subscription service, where you can get access to an entire online library for less than the price of a single book per month. With over 1 million books across 1000+ topics, we’ve got you covered! Learn more here.

Look out for the read-aloud symbol on your next book to see if you can listen to it. The read-aloud tool reads text aloud for you, highlighting the text as it is being read. You can pause it, speed it up and slow it down. Learn more here.

Yes! You can use the Perlego app on both iOS or Android devices to read anytime, anywhere — even offline. Perfect for commutes or when you’re on the go.

Please note we cannot support devices running on iOS 13 and Android 7 or earlier. Learn more about using the app.

Please note we cannot support devices running on iOS 13 and Android 7 or earlier. Learn more about using the app.

Yes, you can access The Purchasing Machine by R. David Nelson,Patricia E. Moody,Jon Stegner in PDF and/or ePUB format, as well as other popular books in Business & Business Strategy. We have over one million books available in our catalogue for you to explore.

Information

1

THE SEARCH FOR THE BEST

Unseen Gains, Lost Profits

EVERY DAY, thousands of companies leave billions of dollars on the table, hard-earned dollars that could have appeared in lower consumer prices, exciting products or fatter shareholder returns. The losses are not leveraged cuts demanded by Lopez-type leaders, but invisible, unrealized savings that could put their organizations in the top tier of healthy, resilient supply management leaders. And every day, those same millions—lost opportunities—slip into someone else’s pocket as the silver certificates flutter and drift farther away from their original owners. Profitable majors like Daimler/Chrysler, Honda of America, Harley-Davidson, IBM, and John Deere all recognize the power of profits realized when supply management professionals focus their attention on best practices in all areas of their operations, and these winners continue to reap the benefits of their intense cost focus. In these unique and powerful supply management leaders, the discipline of acquiring and moving material has become a key strategic advantage that enables lean manufacturing and responsive customer focus.

Unfortunately, although most industries cannot afford to let their profits blow away, many of them don’t even notice the constant slipping away of cash. Sure, they have studied and struggled with MRP systems, ERP, outsourcing, and supplier development, and some of these techniques have produced temporary, noticeable gains. But their central focus is tuned to tracking everyday purchasing challenges of delivery and quality, and their peripheral vision is not engaged. Some of them may be too preoccupied with manufacturing to see the areas at other ends of the supply chain.

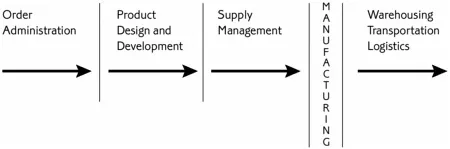

Opportunities for enormous savings in time and money lie at the far ends of the supply chain, most notably in procurement and design and development. In the middle, where manufacturing occupies a thin slice that converts an idea through the delivery process to consumable cash, processing operations account for an increasingly smaller slice of the continuum, because most world-class organizations have for the past fifteen years or so addressed and conquered manufacturing weak points. The problems of excess inventory, waste in the process, bad quality, inflexibility in scheduling, and a better and more professional workforce are well on their way to extinction. The expected result—truly flexible, lean manufacturing—will have been achieved among the winners in most manufacturing sectors within the next ten to twenty years or so.

What remains, therefore, is the challenge of bringing procurement in an extended enterprise into an equally powerful and responsive strategic position.

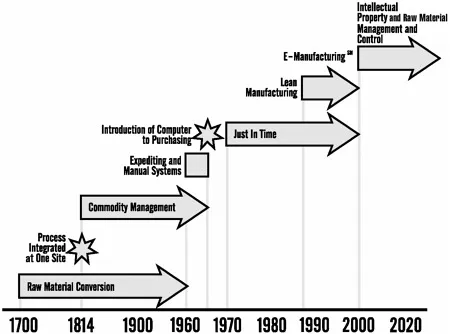

Manufacturing’s Transformation

The past two hundred years have seen a long series of process and human innovations in the area of manufacturing, starting with Francis Cabot Lowell and Paul Moody’s reintegration of the disparate textile processing functions in a single mill on the banks of the Charles River. These entrepreneurs, and a few other members of an enterprising elite called the Boston Manufacturing Company, realized 200 percent and more profits through use of simple economies of scale and expansion: bigger brick mills; longer days; faster machines; more

The Manufacturing Continuum

Opportunities = time, quality, cost, flexibility

Copyright 1998 Patricia E. Moody, Inc.

Figure 1.1 The Manufacturing Continuum*

*From Patricia E. Moody and Richard E. Morley, The Technology Machine: How Manufacturing Will Work in the Year 2020 (New York: The Free Press, 1999).

workers; taking raw material—cotton—and carding, dying, weaving, rolling, and shipping finished goods from a single location. Issues around purchasing and logistics—where and when to acquire the next raw material shipment, where to store the in-process goods, and how to ship out to a market screaming for North American goods—were smaller questions than issues involving direct labor and the machinery that drove the looms. Innovation, therefore, centered on improving, which usually meant going faster, basic production operations. Workforce policies around productivity focused on speed rather than intelligence, perhaps even more than quality.

Limitations of Bigger, Faster Growth

This profit model preceded what we have come to call Taylorism, the perfected system of standards and incentives that further controlled and “improved” how human hands worked. Finally, as competitive threats shifted profits out of the Western world to Eastern production centers like Japan, North American manufacturing leaders adopted in quick succession a series of episodic moves toward better quality, MRP systems, workforce teams and profit sharing, reengineering, and finally lean manufacturing.

Purchasing—Unscathed by “Improvements”

Still, although the huge improvement waves rolled through the ranks of manufacturing planners, purchasing remained relatively untouched. As late as the early 1990s, many organizations could point to no integrated systems assist that completely eliminated paperwork transactions, for example, or that linked purchasing to other production operations. Purchasing systems were an afterthought, frequently too complex to manage quickly or too awkward to change directions. Headlines about procurement tended to focus on cost-cutting drives and limited efforts to roll procurement into the picture.

The Manufacturing Continuum

To some degree, purchasing professionals have enjoyed a pleasant separation from other siloed functions (see Fig. 1.1); twenty years ago few buyers, for example, set foot in their shops or at their suppliers’ sites. It was even possible to plan and manage entire commodities in the computer industry without ever having touched a motherboard or heard the hum of a disk drive. The typical buyer/planner’s day centered on acquisition and tracking of materials at what was considered competitive prices. Strategically, few purchasing professionals participated in business planning decisions; tactically, purchasing planners, buyers, and expediters could not be overlooked because they frequently compensated for system and supplier failures—missed performance in deliveries or quality—a conflicted position from which no human could easily find resolution or progress.

Where manufacturing pioneers evidenced a dedication to bricks and mortar, and more and bigger machinery, purchasing studied and practiced the art of negotiation, business travel, gifting, and locating back-up supply strategies. For a few years, this approach worked, but as operations professionals redrew their landscape, procurement was challenged to get involved. Technology advances—the CNC machine, the PLC, the personal computer, and the Toyota Production System—took large chunks of direct and indirect labor dollars out of product processing and shifted the mix of labor to materials.

Further, as some companies examined their dedication to vertical integration, they migrated toward perfecting a few single competencies. They chose to “offload” certain processing steps, for example, “to the experts.” Where companies like St. James Paper owned forests, shipped and stripped logs, and transported finished product on their own trucks, other commodity producers began to disinvest, freeing up cash to be more carefully applied among competing suppliers.

Shifting a percentage of in-house produced components and assemblies grew the second tier producers, which raised purchasing’s strategic importance within large organizations. It is not unusual for final assembly producers to purchase over 50 percent of the components, making them the assembly and procurement experts and a world of specific commodity competitors. So as manufacturing trimmed down and tried to speed its own processes, procurement found itself with more of the dollar responsibilities for sourcing into final assembly plants, a task most purchasing professionals were unprepared for, and surprisingly, were somewhat blind to. The shift happened almost overnight.

Life Cycles—From Seasons to Months, from Days to Hours . . .

The electronics world grew and adopted new technologies the way farmers used to plan and harvest crops. Computers, for example, during the seventies and eighties were built to a lurchy, spastic rhythm dictated by huge market swings and technology challenges. Pioneers struggled with the movement from core to semiconductor memories, proprietary software and extremely specialized equipment supported massive in-house production of everything from motherboards, to displays, to simple cable assemblies. Completely vertically integrated companies had essentially created a deadly mutual dependence between manufacturing and purchasing; manufacturing pros felt they were all-powerful and decisive, as did purchasing, but all were ruled by marketing and accounting gurus.

But when, in the mid-seventies, the twin stars of predictable, consistent quality aligned with leakage of technology to smaller company experts, the big computer makers—Digital, Data General, Computervision, IBM—found good reason to “get out of town,” to outsource bigger and bigger pieces of their products. Who wanted to be in the business of forecasting, stocking, sourcing, building, storing, shipping, and redesigning thousands of varieties of cable assemblies, for example? Why not shift the burden to the folks who really wanted to be in that high-volume, custom business? That shift to outsourcing—from 10 or 20 percent outsourced material to 50, 60, even 70 percent—marked the rise of professional purchasing and supply management, the birth of the extended enterprise, and the need for this and the next generation’s purchasing executives to rise to the challenge of becoming strategic enterprise leaders. Quite a challenge.

The Vision—Supply Management Twenty Years Out

When Fujitsu joined with EMS (electronic manufacturing services) provider EFTC, of Denver, Colorado, the result was a movement in the electronics industry’s restructuring—the next stage—that will take supply management professionals out of the world of purchasing into strategic sourcing that will direct sourcing and allocation of ideas, as well as materials. If what we see for the next twenty years happens as quickly as the demassification of vertically integrated electronics giants in manufacturing of the 1980s, we believe that purchasing is not ready for a shift of such amplitude.

The EFTC/Fujitsu alliance proves the point. Like another success story, EMC, the Massachusetts Miracle producers of high-end mass storage devices, EFTC started its corporate life in a less glamorous, dirtier career, making boards for big customers. The company discovered and enlarged on its repair and logistics talent to transform a piece of its business into an original equipment provider. In other words, EFTC made history in the computer world by taking on the assembly and order administration of Fujitsu computer orders through a third-party provider remote to Japan—a Tennessee plant site. This restructuring of the building blocks of a typical computer introduced yet more demands on sourcing that sought to manage not only material being purchased, used, and shipped but also designs. Completing manufacturing in an area remote to headquarters is distributed, intelligent manufacturing; purchasing and supply management professionals must be able to support this new production method in other industry sectors all over the world. It is the biggest challenge procurement professionals have faced in over twenty years, and most of them are not ready. The shift for purchasing, therefore, over the past 150 years is historic:

Figure 1.2 The Procurement Continuum to E-ManufacturingSM

E-Manufacturing (E-Man),SMIntelligent Manufacturing Distributed Globally

The progression of the procurement continuum visibly demonstrates several key challenges facing overwhelmed purchasing professionals today:

First, they must broaden their vision to understand and possibly direct the quick and perfect completion of many high-technology tasks.

Second, they must understand and broaden their vision, in preparation for leading their enterprise team in both material and intellectual property acquisition and use.

Third, they ...

Table of contents

- Cover

- Advance Praise for The Purchasing Machine

- Colophon

- Also By

- Title Page

- Copyright

- Dedication

- Contents

- FOREWORD BY R. GENE RICHTER

- PREFACE

- INTRODUCTION

- 1

- 2

- 3

- 4

- 5

- 6

- 7

- 8

- 9

- 10

- BIBLIOGRAPHY

- ACKNOWLEDGMENTS

- INDEX

- ABOUT THE AUTHORS