![]()

CHAPTER 10

SAFETY RELIEF VALVES

The primary function of a pressure relief device is to prevent overpressure by automatically opening and releasing a volume of fluid (gas or liquid) from within the vessel when a predetermined maximum pressure is reached. Acting as a ‘last resort,’ these fully mechanical devices are designed to open when an overpressure situation occurs within a process pressure system, protecting not only life, but safeguarding the investment and plant itself.

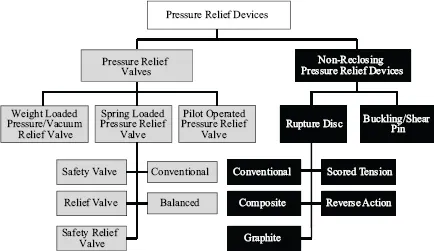

Such devices have been around since the 1600s and may be classified as either reclosing or non-reclosing (Figure 10.1).

Pressure safety relief valves should be taken very seriously. Manufactured from castings, they may not look very sophisticated, but in their design, accuracy, and function, they resemble a delicate instrument, while at the same time, performing an essential role. Self-contained and self-operating, they respond to system conditions and prevent catastrophic failure when other instruments and control systems fail to control process limits adequately.

10.1 HISTORY

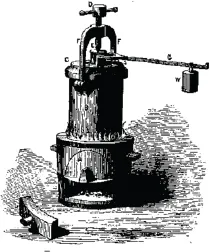

It is usually supposed that the Frenchman Papin was the inventor of the safety valve, which he first applied about in 1682 to a digester. The valve was kept closed by means of a lever and movable weight; sliding the weight along the lever enabled Papin to keep the valve in place and regulate the steam pressure (Figure 10.2).

However, it now appears that safety valves were already in use some 50 years earlier by the German Glauber and that Papin only improved on Glauber’s device. In Glauber’s treatise on philosophical furnaces, translated into English in 1651, he describes how he prevented retorts and stills from bursting from an excessive pressure. A conical valve was fitted, being ground air-tight to its seat, and loaded with a ‘cap of lead,’ so that when the vapor became too ‘high,’ it slightly raised the valve and a portion escaped. The valve then closed again on itself, ‘being pressed down by the loaded cap and so kept closed.’

Figure 10.1. Family of pressure relief devices, classified as either reclosing or non-reclosing.

Figure 10.2. Papin’s safety valve was kept closed by means of a lever and movable weight. Sliding the weight along the lever kept the valve in place and regulated the steam pressure.

The idea was followed up by others, and we find in the art of distillation, by John French, published soon afterward in London, the following concerning the action of such safety valves:

Upon the top of a stubble (valve) there may be fastened some lead, that if the spirit be too strong, it will only heave up the stubble and let it fall down.

It should be realized that the word ‘steam’ was unknown at the time and was only coined sometime later. In its place, we find the words ‘vapor,’ ‘spirit,’ ‘smoke,’ and even, ‘ghost.’

In the early 1800s, there were literally thousands of boiler explosions in the United States and Europe. However, there were no legal codes for boilers in the United States. During the five years between 1905 and 1911, there were 1,700 boiler explosions resulting in 1,300 deaths in the New England region of the United States alone.

Boiler failure in Brockton, Massachusetts, on March 10, 1905, at the Brockton Shoe Factory resulted in 58 deaths and 117 injuries, and completely leveled the factory.

In 1906, Massachusetts established a five-man Board of Boiler Rules, whose charge was to write a boiler law for the state. This was published in 1908. And, in 1911, the State of Ohio enacted a boiler law.

By 1911, the year in which the ASME Council appointed a committee to formulate a boiler code, there were laws and regulations in effect in 10 states and 19 metropolitan areas. The individual state requirements differed greatly from one another, so a boiler built in one state could not be installed in another state. Consequently, the ASME Council established the Boiler Code Committee to prepare a standard that could be accepted by all states. The committee’s mission was to formulate a standard specification for the construction of steam boilers and other pressure vessels.

In 1916, the ASME Council approved the formation of the Conference Committee to provide technical input, as it sees fit, to the additions and revisions to the Boiler and Pressure Vessel Code.

All the provinces in Canada, 48 of the 50 states of the United States, and various regulatory agencies around the world have adopted, by law or regulation, various sections of the Boiler and Pressure Vessel Code.

The American Society of Mechanical Engineers was asked to formulate a design code. The boiler and pressure vessel committee was formed, and hence, the ASME Section 1 for fired vessels was formulated, becoming a mandatory requirement for all states that recognized the need for regulation. The sole purpose of a pressure-relieving device (safety relief valve) is to protect life and property.

10.2 DEFINITIONS

The terms ‘safety valve’ and ‘safety relief valve’ are generic terms that describe a variety of pressure relief devices designed to prevent excessive internal fluid pressure build-up. One of the first problems encountered in the field of pressure safety relief valves lies in the differences in terminology used between the United States and Europe.

One of the most important is that a valve referred to as a ‘safety valve’ in Europe is referred to as a ‘safety relief valve’ or ‘pressure relief valve’ in the United States. Furthermore, the term ‘safety valve’ in the United States generally refers specifically to the full-lift type of safety valve used in Europe.

The European standards (BS 6759 and DIN 3320) provide the following definition:

Safety valve: A valve that automatically discharges a certified amount of fluid to prevent a predetermined safe pres...