Materials, Manufacturing Technology, Electronics And Information Science - Proceedings Of The 2015 International Workshop (Mmtei2015)

Proceedings of the 2015 International Workshop on Materials, Manufacturing Technology, Electronics and Information Science (MMTEI2015)

- 452 pages

- English

- ePUB (mobile friendly)

- Available on iOS & Android

Materials, Manufacturing Technology, Electronics And Information Science - Proceedings Of The 2015 International Workshop (Mmtei2015)

Proceedings of the 2015 International Workshop on Materials, Manufacturing Technology, Electronics and Information Science (MMTEI2015)

About this book

This proceedings consists of fifty one selected papers presented at the 2015 International Workshop on Materials, Manufacturing Technology, Electronics and Information Science (MMTEI2015), which was successfully held in Wuhan, China during October 9–11, 2015.

MMTEI2015 covered a wide range of fundamental studies, technical innovations and industrial applications in the 4 areas, namely Material Science and Application, Mechanical Engineering and Mechatronics,Electronics Engineering and Microelectronics, and Information Science.

This workshop aims to provide a forum for scientists, scholars, engineers and students from universities all around the world and the industry to present ongoing research activities, and hence to foster research relations between universities and the industry. All accepted papers were subjected to a strict peer-review process by 2-3 expert referees.

Contents:

- Material Science and Application

- Mechanical Engineering and Mechatronics

- Electronics Engineering and Microelectronics

- Information Science

Readership: Researchers and professionals in electrical and electronics engineering, material engineering and computer networks.

Mechanical Engineering;Materials Engineering;Electronics Engineering Electrical Engineering;Computer Science Key Features:

- The proceedings collected together the latest late-breaking contributions funded by Chinese government research agencies in Material Science and Application, Mechanical Engineering and Mechatronics, Electronics Engineering and Microelectronics, and Information Science

Frequently asked questions

- Essential is ideal for learners and professionals who enjoy exploring a wide range of subjects. Access the Essential Library with 800,000+ trusted titles and best-sellers across business, personal growth, and the humanities. Includes unlimited reading time and Standard Read Aloud voice.

- Complete: Perfect for advanced learners and researchers needing full, unrestricted access. Unlock 1.4M+ books across hundreds of subjects, including academic and specialized titles. The Complete Plan also includes advanced features like Premium Read Aloud and Research Assistant.

Please note we cannot support devices running on iOS 13 and Android 7 or earlier. Learn more about using the app.

Information

CHAPTER 1

Material Science and Application

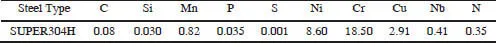

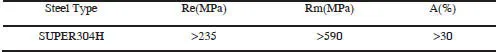

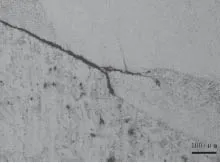

Welding defects of SUPER304H steel and their countermeasures*

Xiao-Ming Liu†, Yun-Peng Gao, Zhi-Gang Wei

Inner Mongolia Electric Power Science and Research Institute,

Hohhot, 010020, China

†E-mail: [email protected]

Hou-Xia Yan

JINSHAN Thermal Power Plant of Inner Mongolia

Energy Power Investment LTD.

Hohhot, 010106, China

E-mail: [email protected]

1. Introduction

2. Experimental Materials and Methods

3. Welding Defects and Its Countermeasures

3.1. Welding defects caused by material property

Table of contents

- Cover

- Halftitle

- Title

- Copyright

- Preface

- Contents

- Chapter 1 Material Science and Application

- Chapter 2 Mechanical Engineering and Mechatronics

- Chapter 3 Electronics Engineering and Microelectronics

- Chapter 4 Information Science

- Author Index