eBook - ePub

Applied Engineering, Materials And Mechanics - Proceedings Of The 2016 International Conference (Icaemm 2016)

Proceedings of the 216 International Conference on Applied Engineering, Materials and Mechanics (ICAEMM 216)

- 352 pages

- English

- ePUB (mobile friendly)

- Available on iOS & Android

eBook - ePub

Applied Engineering, Materials And Mechanics - Proceedings Of The 2016 International Conference (Icaemm 2016)

Proceedings of the 216 International Conference on Applied Engineering, Materials and Mechanics (ICAEMM 216)

About this book

ICAEMM2016 is an annual international conference that aims to present research outcomes undertaken in applied engineering, materials and mechanics. The book is a collection of 48 selected peer-reviewed articles, organized into three main chapters

Frequently asked questions

Yes, you can cancel anytime from the Subscription tab in your account settings on the Perlego website. Your subscription will stay active until the end of your current billing period. Learn how to cancel your subscription.

No, books cannot be downloaded as external files, such as PDFs, for use outside of Perlego. However, you can download books within the Perlego app for offline reading on mobile or tablet. Learn more here.

Perlego offers two plans: Essential and Complete

- Essential is ideal for learners and professionals who enjoy exploring a wide range of subjects. Access the Essential Library with 800,000+ trusted titles and best-sellers across business, personal growth, and the humanities. Includes unlimited reading time and Standard Read Aloud voice.

- Complete: Perfect for advanced learners and researchers needing full, unrestricted access. Unlock 1.4M+ books across hundreds of subjects, including academic and specialized titles. The Complete Plan also includes advanced features like Premium Read Aloud and Research Assistant.

We are an online textbook subscription service, where you can get access to an entire online library for less than the price of a single book per month. With over 1 million books across 1000+ topics, we’ve got you covered! Learn more here.

Look out for the read-aloud symbol on your next book to see if you can listen to it. The read-aloud tool reads text aloud for you, highlighting the text as it is being read. You can pause it, speed it up and slow it down. Learn more here.

Yes! You can use the Perlego app on both iOS or Android devices to read anytime, anywhere — even offline. Perfect for commutes or when you’re on the go.

Please note we cannot support devices running on iOS 13 and Android 7 or earlier. Learn more about using the app.

Please note we cannot support devices running on iOS 13 and Android 7 or earlier. Learn more about using the app.

Yes, you can access Applied Engineering, Materials And Mechanics - Proceedings Of The 2016 International Conference (Icaemm 2016) by Jong Wan Hu in PDF and/or ePUB format, as well as other popular books in Technology & Engineering & Civil Engineering. We have over one million books available in our catalogue for you to explore.

Information

The mechanical properties of SS400C3 plate by CSP produced under the hot rolled pickled deep drawing

Y. X. Liua,*, Y. J. Meng, W. X. Lib, X. Guan and B. Yangc

Hebei College of Industry and Technology,

Shijiazhuang 050000, China

E-mail: a[email protected]; b[email protected]; c[email protected]

Shijiazhuang 050000, China

E-mail: a[email protected]; b[email protected]; c[email protected]

The mechanical properties of hot rolled picked deep drawing plate were investigated with thickness of SS400C3 plate changing under new technological parameters of CSP. Results showed that the mechanical properties of SS400C3 plate depend on thickness. The δs and δb were reduced and the δ increases with an increase in the thickness of the SS400C3 plate. The technological parameters were adjusted by the thickness of SS400C3 plate.

Keywords: CSP; Continuous metal cast process; Rolling technology; Mechanical property.

1.Introduction

Compared with the corresponding grade cold rolling plate, the hot rolling and pickling deep drawing board can omit the cold rolling and annealing process, reduce the production cost, and the hot rolling pickling deep drawing board has the high strength, high elongation [1, 2] and good formability. According to the inherent characteristics of CSP process, the process conditions of SS400C3 production of [4], low carbon, low silicon, low manganese, appropriate relaxation of C, [5-10] and Si were used in the design of chemical composition.

2.Experimental Materials and Methods

Adopt front cooling: value: 1 First. Cooling water setting 75%. T 6.0mm, head of 6 meters is not cooling, T > 6.0mm, the head of 8 meters without cooling. The average mill inlet temperature at 1041 degrees Celsius, finishing temperature at 854 degrees Celsius, coiling temperature at 601 degrees Celsius. From the temperature of the average temperature control of the key point to achieve the standard temperature control requirements, the intermediate billet set up to meet the requirements of the regulations.

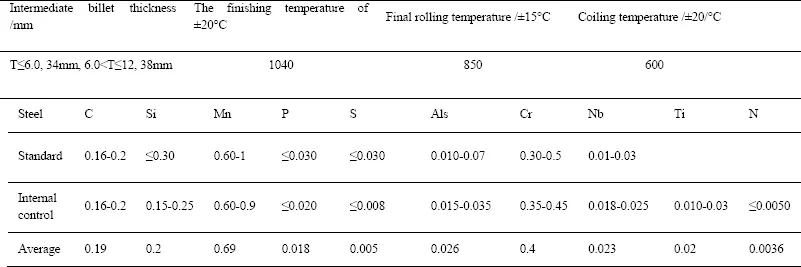

The rolling speed is changed with the different thickness steel witch will be rolled form thickness of 50 mm to 1~4 mm thick steel, and the process parameters such as Table 1.

The chemical composition of the experimental steel was SS400C3, and the Si, P and S of the experimental steel was lower than that of the experimental steel, as shown in Table 2. Analysis of the chemical constituents in the steel plate by using the PROFILERHR glow spectrum analyzer.

The steel strip samples are drawn from the outer and inner ends of each roll, vertical to rolling direction, GB/T228-2002 and 1/4 of the strip width −35 and 1/2. The sample is made into tensile specimens. The mechanical properties of the specimens are tested by using 20mm * 80 GB/T228-87 standard test.

3.Experimental Results and Discussion

3.1.Mechanical performance analysis

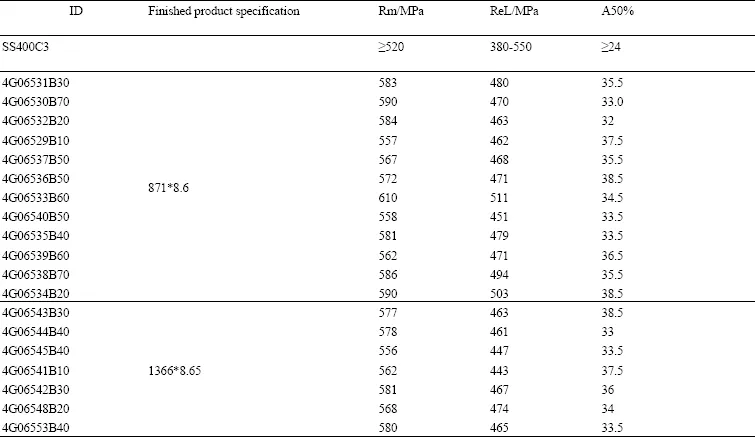

Table 2 for the detection of SS400C3 steel plate thickness specifications and mechanical properties, through the thickness of the 1.8~4mm and the width of the 1210~1600mm number of SS400C3 rolling plate for statistical analysis, experimental results are more universal.

Table 1.The technological parameters of CSP.

Table 2.Mechanical properties of SS400C3 plate.

From the physical performance test results, the performance stability is better, the strength of the surplus amount is appropriate, the extension rate fluctuations slightly larger. 3.0mm's SAPH400 thickness specifications of the low tensile strength, yield strength of the surplus, the extension rate also meet the standard requirements. To adjust the process of SAPH400, the first three sections of the cooling pipe before the restoration of cooling mode to the front cooling, Vlave Frist from 13 to 1, the cooling method to adjust for the strong cold, in addition to consider increasing the C content, to improve the tensile strength.

3.2.Organization analysis

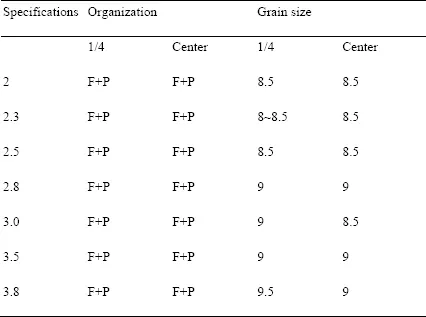

The microstructure of SS400C3 steel was shown in Table 3, microstructure and morphology of F+P. The microstructure of SS400C3 steel was composed of ferrite and pearlite, and the grain size of the kinds of steel was more uniform, and the grain size of the three steel was uniform. The grain size of the 1/4 is slightly higher than that of the center. This is also the main reason for the difference of mechanical properties between different rolling plate thicknesses.

Table 3.Microstructure and grain size analysis of SS400C3 plate.

4.Conclusions

Through the analysis on the mechanical properties of CSP rolling plate S400C3 seen SAPH400 3.0mm specifications tensile strength is low, standard is equal to or more than 400MPa actual 408Mpa. Close to the lower limit, the production layer of cold front set tube has been restored for use. The first valve 1 fore stage cooling, adjust the cooling mode by a weak cold adjustment for strong cold, the tensile strength increased. In addition, the content of C can be improved, the content of Mn can be decreased, and the ratio of yield and yield can be decreased.

References

1.P. C. Zambrano, M. P. Guerrero and R. Colas, et al. Microstructural analysis of hot - rolled low carbon steel strips. Mater. Characterization. 47, 275-282 (2001).

2.G. Flemming, F. Hoffman and W. Rohde, et al. The CSP plant technology and its adaptation to an expanded production progranmme. Metall. Plant Technol. Int. 16(2) 84–96 (1993). C. Jarlskog, CP Violation (World Scientific, Singapore, 1988).

3.Y. Chen, D. Z. Zhong, J. N. Liu, H. Xie, J. Liu, T. Peng, R. M. Zhao, Y. Zhang, W. S. Liu and Z. G. Yang, Microstructuer, properties and application of hot rolled and picked deep drawing steel strip. Iron and Steel, 35(3) 39-42 (2004).

4.S. J. Cobo and C. M. Sellars, Microstructural evolution of austenite under conditions simulating thin slab casting and hot direct rolling. Ironmak. Steelmak. 29(3) 230-236 (2001).

5.N. Zentara and R. Kasper, Optimization of hot rolling schedule for direct charging of thin slabs of Nb – V microalloyed steel. Mater. Sci. Technol. 10, 370-376 (1994).

6.J. K. Brimacmbe and I. V. Samarsekera, The challenge of thin slab casting. Iron and Steelmaker, 21(11) 29-39 (1994).

7.R. Kasper, N. Zentara and J. C. Herman, Direct charging of thin slabs of a Ti-microalloyed low carbon steel for cold forming. Steel Res. 65(7) 279-283 (1994).

8.X. D. Huo, Y. L. Wang, D. L. Liu, N. J. Chen, Y. L. Kang, J. Fu, Z. B. Wang and G. J. Chen, Study on precipitation and microstructure evolution of low carbon steel produced by compact strip production. Mater. Sci. Technol. 12(12) 167-171 (2004).

9.J. W. Christian, The Theory of Transformation in Metals and Alloys, Pergamon, Oxford, p. 418 (1975).

10.F. Spaepen, A structural model for the solid-liquid interface in monatomic systems, Acta. Metall. 23, 729 (1975).

_______________________________

* Corresponding author.

Effect of extrusion deformation on

microstructure evolution of

spray-formed 7055 aluminum alloy

microstructure evolution of

spray-formed 7055 aluminum alloy

Y. Z. Xiang*, J. S. Qiao, P. J. Wang and H. Zhang

Department of Materials Science and Engineering, Lanzhou University of Technology,

Lanzhou, Gansu, China

State Key Laboratory of Gansu Advanced NonFerr...

Lanzhou, Gansu, China

State Key Laboratory of Gansu Advanced NonFerr...

Table of contents

- Cover Page

- Title

- Copyright

- Preface

- Contents

- 1. The mechanical properties of SS400C3 plate by CSP produced under the hot rolled pickled deep drawing

- 2. Effect of extrusion deformation on microstructure evolution of spray-formed 7055 aluminum alloy

- 3. Innovation Design of Flexible Manipulator by TRIZ

- 4. Application of TRIZ contradiction theory In innovative design of the potted filling soil mechanism

- 5. Institutional analysis of the development and policy on Sino-US energy on saving and new energy vehicles

- 6. Improved performance of LiCoO2 cathode enabled by electrode sputtering coating with Al2O3

- 7. Antimicrobial finishing of polyester fabrics using silica nanoparticles

- 8. Preparation and characterization of manganese dioxide (MnO2) as a cathode catalyst for direct methanol fuel cells

- 9. Numerical simulation of the energy deposition in the HIPIB irradiating process of Ti target

- 10. Research on the performance of the offshore-platform air filter based on the porous medium model

- 11. Analysis of the reasons behind the fracture of the 220kV pipe busbar horizontal line clamp

- 12. Analysis of hydrocarbons and carbon dioxide emissions from diesel common rail engines and finding the correlation between velocity and emissions in the cases of Lancia Thesis and Citroen C4

- 13. Effect of Na2O on acid resistance of alumina-based ceramic proppant

- 14. The application of digital technologies in furniture design

- 15. Research on the bored pile construction technique of alternating screw drills and percussion drills

- 16. Research on construction technology of color steel plate roof in situ profiling and installation

- 17. Study on a flexible manipulator platform

- 18. Effect of pore solution alkalinity of fly ash-cement mixture on ASTM C 1260/C 1567 mortar bar expansion

- 19. Effect of vibration mixing on performance of recycled concrete

- 20. Research on mechanical strength and residual stress in friction stir welds of spatial 3-D circular structure

- 21. Cracking pattern analysis of concrete pavement on asphalt stabilized base and Econo-Crete base

- 22. A review of coastal hazard management performances

- 23. Mode confusion for estimating the longitudinal thermal stress of continuously welded rail

- 24. Investigation of pore size distribution in cement paste using mercury intrusion porosimetry and backscattered electron image analysis

- 25. Impressed current cathodic protection behavior of reinforced concrete specimen using MMO Ti-Mesh anode

- 26. The unascertained regression analysis method and its application in building material sales prediction

- 27. Research on inventory control for equipment maintenance spare parts

- 28. Impact of environmental regulation on corporate environmental investment

- 29. Using frequency sweep strain control to study the rheological properties of Malaysian’s asphalt binder

- 30. Numerical simulation of heated concrete failure on the levels of the meso-structure

- 31. Analysis of warping deformation of laser bracket based on moldflow

- 32. Prediction deterioration of insulation process based on the partial discharge thermal fluctuation theory

- 33. A file storage service on a cloud computing environment for digital libraries

- 34. A design procedure for the hinge system in a heavy foldable container

- 35. Viable seismic strengthening solutions for RC wide beam-column joints

- 36. Optimization of gas turbine fir-tree attachment based on redesigning the transition area with double-arc and spline curve

- 37. Compensation of the deformed ram spindle of a horizontal boring machine

- 38. Study on motion response of spar foundation based on AWQA

- 39. Numerical analysis on the effects of shoal on the ship wave

- 40. Investigation of characteristics of wave induced currents using hydraulic model experiment

- 41. The design and application of motion control system based on PLCopen standard

- 42. Dye-sensitized solar cells using liquid phase deposition titania thin films

- 43. Chebyshev cardinal functions for solving obstacle boundary value problems

- 44. Experimental study on linear pressure loss of spray hose

- 45. MEMS based device for steering wheel angle experimental measuring

- 46. Mechanical property changes of KNO3 salt bath nitrided duplex stainless steel

- 47. Wastewaters treatment and drinking water purification with complex automated electrolysis unit

- 48. Development and application of comprehensive drought evaluation model for irrigation district in North China