![]()

1

Introduction to Molecular Machines

1.1 Preliminary Aspects of a Conventional Machine

A machine is a piece of equipment having several moving parts to perform definite work with the aid of power. Machines have contributed immensely to the growth of human civilization. Manufacturing, aesthetic design of products, swift and safe transportations, instant communications are some aspects which have grown tremendously. The concept of machines started from the start of human life before science was developed. This happened due to necessities for survival and the need to improve the quality of food, cloth, shelter and communication. Machines have changed standard of life by improving economy and ease to get things. A macroscopic machine generally operates on many components acting together in a synchronized manner to transfer motion, with force, or energy from one component to another to act as independent or multiple units. Some machines are just for storing information through acquisition and processing of data and others are to reduce the amount of work required to accomplish a given task.

Necessity to perform work, available technology and commercialisation are the most important motivating points to improve a machine and also to abolish a machine. For example let us look at the changes and progress in development in watch. Before watch came into existence, sun was one of the sources used as time keeper. There was also a time when only the hour indicator in a watch was good enough to provide information on time. Mechanical energy was the main guiding factors. Accuracy and precision of time started to grow as requirement different activities. Digital display has made it one of the important time-keeping facilities, which is followed by inclusion of more parameters related to day to day activities. Through the advent of scientific knowledge, in present day a watch has multiple components of several electronic gazette and is used multiple purposes. Even a simple watch has various components function together which are pivots, wheels, shafts, ratchets, screws, springs etc. When all components are assembled, independent function of each component becomes a supporting activity and function of the watch is like an integral machine which is focused to precisely describe time at a particular moment.

One way to classify machines is based on performing a task. A class of machine called sorting machine differentiate properties relating to size, shape, strength, color, smell etc. Thus there are many sub-headings under which they will fall. Another way to name a machine is by narrating the name of the job it does. Washing machine is such an example which washes cloths. Vending machine to get tea or coffee, voice recording machine such as tape or video recording machine to make a film are some other examples. Another way to explain machine is by describing a process that attracts the attention of a common man, such as by narrating life-saving machines used in hospital, a vehicle as locomotive machine. A curious mind questions on the points on purpose, power and fuel of a machine. There are other ways to describe a machine, for example a machine may be named by fuel used; such as coal engine, petrol engine, diesel engine, electrical machine, solar machine. There are also machines based on the route or path they follow; for example aviating machine, navigating machine, locomotives, terrestrial machines etc. On the other hand, classification also goes by efficiency so as to call a machine as superfast machine or slow machine. When an integrated job is done by several machines it is customary to describe such units as machinery. Thus, machinery is nothing but a set of unitary machines which can be integrated to perform a job. For example, a locomotive machine is constructed with the help of several machines. United those parts of an integral machine falls under category of machineries needed for locomotive factory. A non-performing or an ideal machine may be referred as equipment; which under suitable conditions can be turned on to perform as machine.

From science and technology point of view systematic and formulated knowledge are essential to improve and understand performances. Understanding on these issues in a quantitative and a methodological way provide means to utilize them to generate higher output. Four factors play pivotal roles to scientifically describe a machine, these are (a) Purpose, (b) Design, (c) Performance and (d) Fuel of a machine.

The basic principle of machine is to get an output and the principle of machine lies on the fact that energy is indiscernible and can be converted from one form of energy to another form. For a machine performing mechanical work two prime physical properties namely force and motion becomes very important. Force in terms of push or pull is required to cause a mechanical movement. Forces operating a machine also occur in pair, involving two objects. These situations can be imagined as one object applying force on another object. As a counter effect an equal amount of opposing force is applied by the other object. Such forces can be contact force arising due to bringing two objects in to contact. It can be a force field created around an area in and around vicinity of the one or both objects. As per the types of work done; exerted forces may be frictional force, compressive force or tensile force.

A simple example of a mechanical machine is a pulley. A simple pulley can be constructed by a putting a rope over a rotatable wheel at a fixed position. By pulling the rope, as the wheel rotates the process helps to lift a large mass (Figure 1.1). Such pulleys are conventionally used to lift water from well when sophisticated machines for the same purpose are not available. Pulley transmits a force which enables the rope to easily lift a weight than the force that would have been required by the rope alone. In other word, pulley acts as a machine to modify applied force on the rope. Hence, input force required to do the work gets reduced. Input force is termed as ‘effort force’ and output force in such a machine is referred to as ‘load force’. Functional and design aspect of the machine is essential to understand working principle of a machine. Design aspect of a machine is also important to increase performance of an existing machine. But, identification of the purpose of a machine helps to define physical quantities to be used as descriptor of performance of a particular machine.

A conventional rotodynamic machine functions with a rotor consisting of a number of vanes or blades. While in operation a relative motion between vanes and the fluid medium in gas or liquid occurs. Momentum of the rotor changes when a fluid having definite momentum moves in a direction tangential to rotating blade and passes through the rotor. On the other hand, a still but rotatable blade starts rotating by flow of a fluid. In this process tangential momentum of the fluid is reduced. Similar rationale is applicable in function of pumps and compressors. In these cases the tangential momentum of the fluid increases which helps to extract work done by the fluid from the moving in or out of the pump or compressor.

Figure 1.1. An example of a pulley.

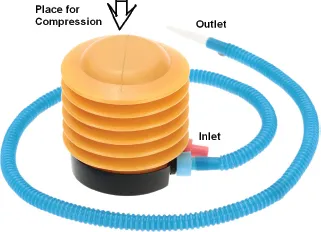

Let us consider a pump as a machine to illustrate its components and functions. Pump belongs to class of machine used to transfer mechanical energy of a rotor to the energy of fluid. There are several sub-classifications of pumps; for example compressor, fan and blower. A compressor is a pump which compresses gas or fluid. The objective of a compressor is to increase pressure of the gas or fluid under consideration (Figure 1.2). The most important physical parameter that relates the output is pressure. On the other hand, fan and blower are used to increase or decrease the flow rate of a gas. In these cases mechanical energy of a rotor is used to increase the kinetic energy of the gas/fluid. Thus, main measurable physical quantity as output in this case is kinetic energy. Mathematically it is given by ½mv2, where m is mass and v is the velocity of the gas/fluid. Thus, in this case mass transfer relates to velocity or acceleration provided to the gas/fluid. Each machine is to give best and suitable output under controlled conditions. For example, a fan has to have control not to cause inconvenience by blowing off the materials in its near vicinity or unless required, pressure exerted by a pump should not lead to an explosion. While utilization of a work it should be possible to regulate the work. Thus, switch and controlling unit becomes essential. To keep a machine in operation external force or stimuli may be required. These forces or stimuli may be acquired from a stored source called as fuel. Alternatively, fuel is required for a machine to operate. Fuel can also be used from a direct source. On the other hand stimuli can be generated from forces such as mechanical, electrical, magnetic, gravitational, light, nuclear forces. Stimuli can also be acquired from another source or diverted form a source which is continuously performing another activity. For example, a pressure can be built by using kinetic energy of flowing water or wind. There are also indirect ways to generate energy and utilize, for example combustion of coal through change of one form of matter to another form. Water transforming to steam is used conventionally in locomotive machines such as in steamers in water transport, balloons in air transport, steam engine of rail etc.

Figure 1.2. A pump to fill balloon with air.

Besides fast and accurate process performed by a machine there are several other issues play roles in improvement as well as utility of an existing version of a machine. For economy purpose the alternative fuel as well as multiple mode of using fuel is very important. Deliberately control on adjustment of input and output of a machine over and above switching on and off, makes a machine versatile. For example, a component called accelerator apparently regulates speed of a car but without a gear it would have very limited performance. Gear has ability to set or modulate ranges of speed that can be altered by accelerator. Thus, gear sets up multiple steps to control and overcome limitation of performance of accelerator. Automation of gear is additional process to sophisticate a locomotive. Embedded computer in such a machine or externally connected computer can be used as the brain of the machine to control all the functions. Further to these, remote control on such locomotive can not only help to keep information on positions and movements in better way but can help in safety measure.

New design, performance, fuel and market economy guides utility of machine utilized in day to day activity. On the other hand machine working with remote controls have great potential and now are routinely used for all kinds of transport systems. But the miniaturisation, integration and automation of machine are universal issues required to make better machine for utilities in a day to day life. Among these requirements miniaturisation has several fundamental basis, as it can be a way to build a machine from molecular understanding to do specific function. Best analogy comes from the function of living beings as each of them perform as integrated machines. In such examples the brain controls output and input. A device or a machine can be very big or very small and their sizes are as per purposes of utilization. Later part of nineteenth century has seen progressive miniaturization of devices and machines has resulted in outstanding technological achievements, especially in the field of information processing.

1.2 Miniaturization of Machines

As mentioned miniaturization of machine is one contention to reduce size and increase efficiency principle.1-6 At this juncture a question can be framed on the workable or working limit of machinery. The original vision on the miniaturization started with the early work during 1950 by of Richard Feynman. He emphasized the possibility to build machines at nano-meter scale. But the initial studies relating to artificial molecular machines were performed since 1827 by Robert Brown. He was a botanist, who discovered haphazard motions of tiny particles under microscope. Such movement of colloidal particles called Brownian motion was explained with the kinetic theory of matter. Brownian motion of the particles was suggested due to bombardment of the particles by molecules present in a colloidal solution. It was like an imagination at that time due to belief that to build a machine at molecular level a hand to handle of same dimension would be required. With the advent of various optical spectroscopic tools coupled with many other tools relating to diffraction, mass, and techniques suitable for surface analysis the issue of hand being miniaturized has got to a comfortable stage. Feynman had also suggested about bottom up procedure to build machinery. He also initiated theoretical construction, build bottom up concept. In his study he used silicon sprayed layer of atoms by another layer of atoms onto a surface. He studied the effect of partial removal of some such layers. Such removal process created moving parts controlled by electric current, at that time such a construction process was predicted to create optical shutter for tiny camera. With such wonderful predictions, subject has continuously grown and become theme for subject with great future. Synthetic chemists started to deal with such research from about year 1970. However, the subject took acceleration around year 1990 with the development of syntheti...