![]()

Chapter 1

Design, Synthesis, and Application of Anisotropic Janus Particles*

Chengliang Zhang†, Fuxin Liang, and Zhenzhong Yang‡

Abstract

In this chapter, we comprehensively introduce the recent developments on anisotropic Janus particles, including hollow structure, non-spherical, sheets/disks, rods/cylinders, ring, etc. Also, we systematically compare different methodologies and present some emerging application examples. At last, we conclude some issues and trending for next research as well.

Keywords: Janus particles, anisotropic, composite, microstructure.

1.1.Introduction

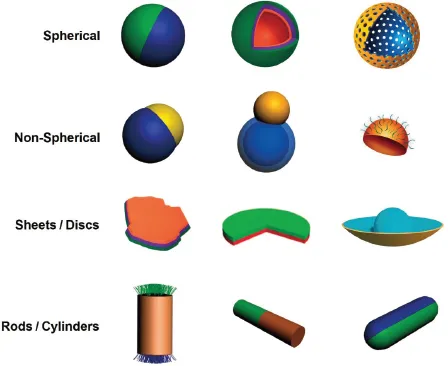

The physical structure (shape and size) and the distribution of chemical composition are two essential defining properties of Janus particles. In last decade, many efforts have been devoted to the precise control of the structure and composition of Janus particles for achieving excellent properties. Janus particles with various shapes and different compositions have been prepared, some of which have demonstrated important and interesting applications. As shown in Fig. 1, the representative shapes of Janus particles include spherical, non-spherical, sheets/disks, rods/cylinders, etc. The particle size varies from micro to nanoscale. The composition contains polymer, inorganic, metal or hybrid materials.

Inspired by the initial research of French scientists [1,2] and encouraged by Gennes’ lecture [3], researchers chose all kinds of spheres as research objects, for example, monodispersed polystyrene (PS) spheres and silica spheres. So, at the first research stage, the Janus particles displayed only chemical asymmetry, not structural asymmetry. Compared with spheres, anisotropic particles have more interesting and amazing properties due to their higher length or diameter or aspect ratio and concomitant structural and chemical distribution. In this chapter, we will focus on Janus particles with anisotropic shapes, especially non-spherical, sheets/disks, rods/cylinders, and other interesting morphologies, and review the synthesis methods and emerging applications of anisotropic Janus particles. Finally, we will present a summary and emerging trends as well.

Figure 1. Schemes of Janus particles with various shapes.

1.2.Janus Hollow Spheres

Spherical Janus particle is the most extensively investigated of this type of particles. The most popular research idea is to compartmentalize two compositions on the exterior surface of the template particles by using a protective interface to separate two different areas, followed by modification of the two half surfaces, respectively. The strategy is versatile. Therefore the compositions of two hemispheres are tunable, for example, polymer/polymer [4], polymer/inorganic [5], polymer/metal (metallic compound) [6], polymer/protein [7], inorganic/organic ligand complex [8] and silica/metal [9]; furthermore, the diameter of Janus spheres can be changed from the nanometer to the micrometer scale by choosing the template particles with different sizes.

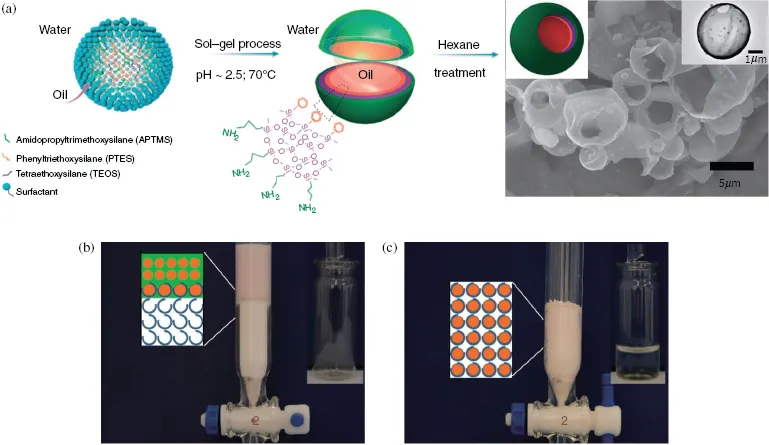

Janus hollow spheres are a special form of spherical Janus particles, and their shell is asymmetric with two different compositions compartmentalized onto interior and exterior surfaces although their outermost surface is centrosymmetric. In 2011, we reported a facile method of large-scale preparation of inorganic Janus hollow spheres with hydrophilic outside surface and hydrophobic inside surface by a self-assembled sol–gel process [10]. As shown in Fig. 2(a), the emulsion is first formed with three different silanes in oil phase. Then, the sol–gel process will be triggered by changing the pH value and temperature. Along with the reaction, the amine- and phenyl-terminated sols can self-assemble at the interface, facing the aqueous phase, and the oil phase, respectively. After the sol–gel process is completed, the oil core is removed by dissolution. Thus the Janus hollow spheres with holes on the shell can be achieved due to osmotic pressure, which is conductive to mass transport. Although the Janus hollow spheres are overall centrosymmetric, the shell is asymmetric with two different compositions compartmentalized onto interior and exterior surfaces. Also, we present an application to demonstrate the properties of Janus hollow spheres. The as-prepared Janus hollow spheres are stacked into a column for separation. When the toluene–water emulsion passes through the column, toluene is absorbed because the hydrophobic cavity is favorable to loading toluene inside, as clear water is eluted (Figs. 2(b) and 2(c)).

Figure 2. (a) SEM and inset TEM images of inorganic Janus hollow spheres. (b) The toluene–water emulsion was added to the chromatography stacked with Janus hollow spheres. (c) Water eluted while toluene was absorbed. Reprinted with permission from Ref. [10]. Copyright (2011) Royal Society of Chemistry.

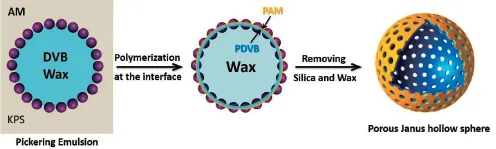

Pickering emulsion is a classic and effective strategy for preparing Janus particles using 3D interface as the protecting layer. We observed that the particles also can be used as templates to create uniform pores. So we combined Pickering emulsion and interfacial polymerization to prepare porous Janus hollow spheres [11]. As shown in Fig. 3, SiO2 particles, wax, oil-soluble monomer and water-soluble monomer are formed through Pickering emulsion. After polymerization at the interface, the amphiphilic copolymer film is formed at the gap between the particles. After removing SiO2 particles and wax, the porous Janus hollow spheres will be formed. The pore size and the shell thickness can be modified by changing the monomer content. In comparison with other porous materials, the advanced property of such Janus particles is to preferentially and easily capture lipophilic molecules and even particles as well inside the cavity.

Figure 3. Schematic synthesis of porous Janus hollow sphere. Reprinted with permission from Ref. [11]. Copyright (2012) Elsevier.

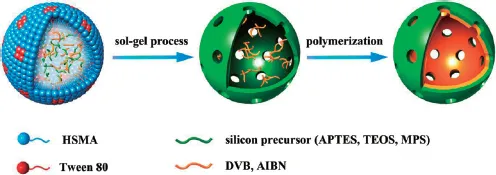

Further, for preparing a robust shell with hard templates (SiO2 particles) free, we proposed another strategy for preparing porous Janus hollow spheres based on the sol–gel process at the emulsion interface and polymer grafting onto the interior surface (Fig. 4) [12]. The binary surfactants instead of SiO2 particles are used to make the transverse channels across the shell due to phase separation. The resulting Janus hollow spheres are further functionalized by growing responsive polymers onto the interior surface for easy loading of the desired materials. In addition, magnetic nanoparticles can be integrated into the composite shell to make the Janus spheres work under a magnetic field.

Figure 4. Schematic synthesis of the Janus cage with polymer–inorganic bilayers. Reprinted with permission from Ref. [12]. Copyright (2013) American Chemical Society.

For showing the special property of such porous Janus hollow spheres, we also presented two interesting examples in controlled loading/release. In the first example [13], we first prepared the porous Janus hollow spheres with the catalyst TiO2 nanoparticles encapsulated inside the cavity (Fig. 5(a)). Then, such Janus hollow spheres were able to concentrate organic compounds from their aqueous surroundings due to their hydrophobic interior surface and transverse channels across the shell. Upon UV irradiation, the organic compounds can be easily decomposed. The method is expected to be used for other kinds of Janus mi...