![]()

Basements

Introduction

Abasement refers to any floor level below the first story in a building that is partly or completely below the exterior grade plane [1] with at least one-half of its floor-to-ceiling height above curb level or above the average natural grade [2]. The space can be utilised in the form of carparks, plant rooms and workshops, or storage, residential, retail and or office areas. As an underground structure, it is susceptible to ground water ingress and external hydrostatic pressure, and subject to a rapid degree of deterioration compared to other building components since it is directly exposed to the surrounding soil conditions. The performance requirements for water-tightness varies depending on the basement usage. For example: (a) some seepage and damp patches are tolerable for carpark, plant rooms and workshops; (b) no water penetration but moisture vapour is tolerable for workshops and plant rooms requiring drier environments (e.g. retail storage areas); (c) dry environment should be provided for ventilated residential and working areas (e.g. offices, restaurants, etc.); and (d) a totally dry environment is necessary for archives and stores requiring controlled environments [3]. Durability is important in the design, construction and maintenance of basements — on top of keeping it moist and damp free — to lessen the frequency of repair and maintenance. It is essential to reduce hydrostatic pressure around the basement structure and prevent the entry of stormwater. The use of reinforced concrete for the basement’s outer wall and the feasible application of a waterproofing system is recommended to prevent water seepage and ensure that the membrane does not lose its protective capacity [4, 5]. The waterproofing membrane material should be selected based on a few criteria, including (a) long term water-tightness; (b) durability in exposure; (c) ease of application; (d) curing period; (e) flexibility; (f ) tensile property; (g) puncture resistance; and (h) compatibility with substrate [5, 6].

Basement area of a retail commercial complex.

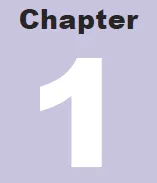

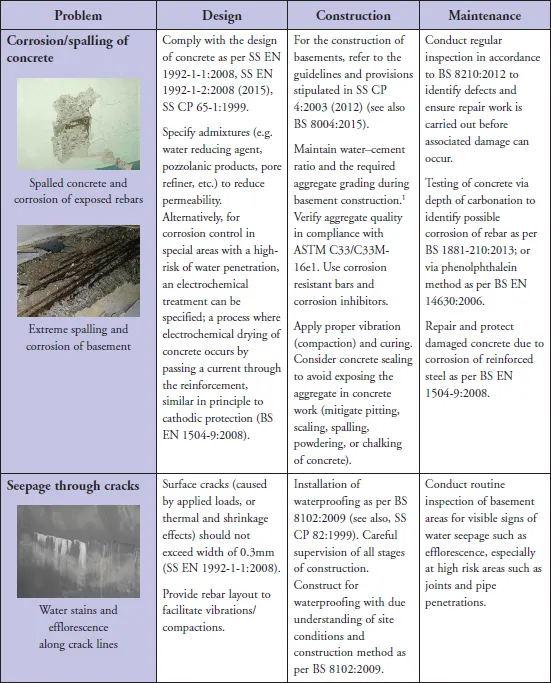

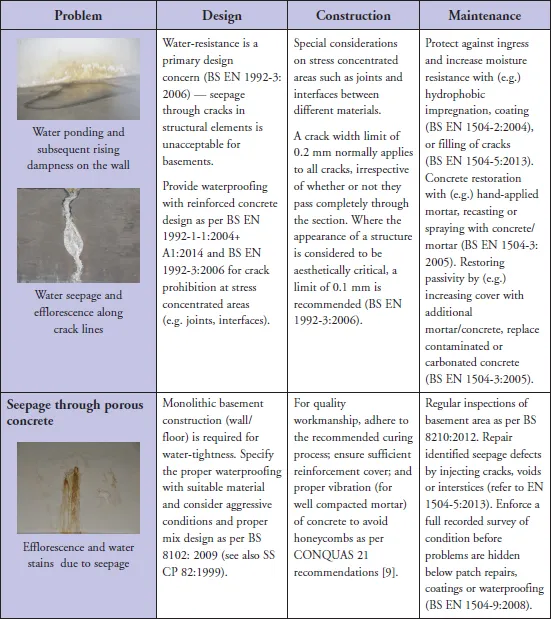

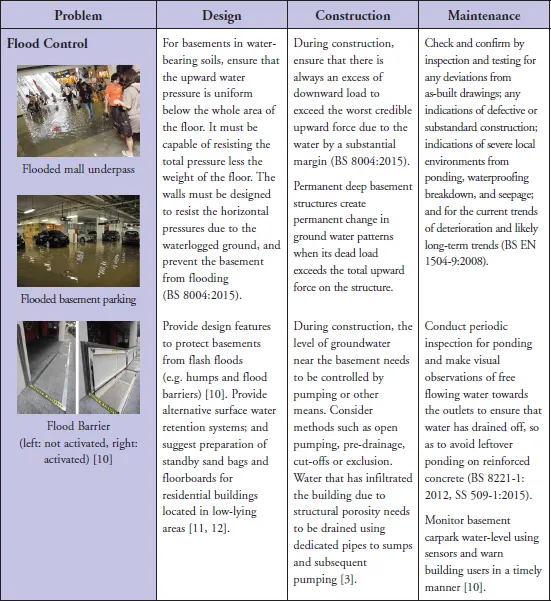

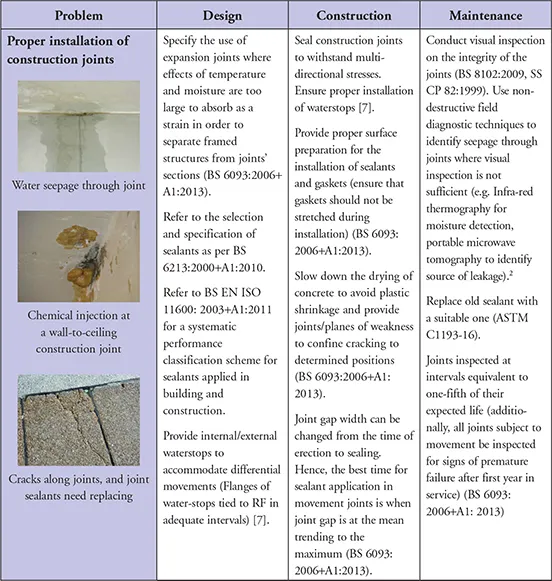

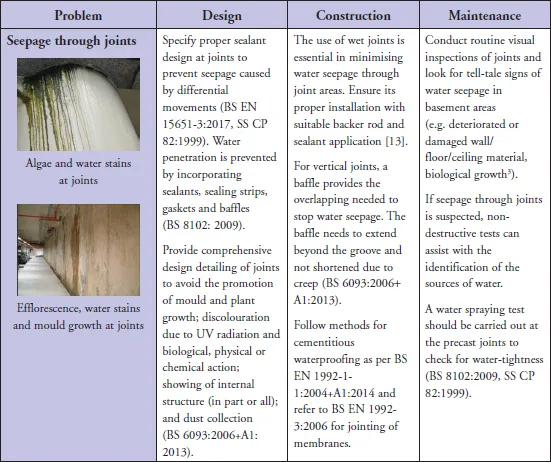

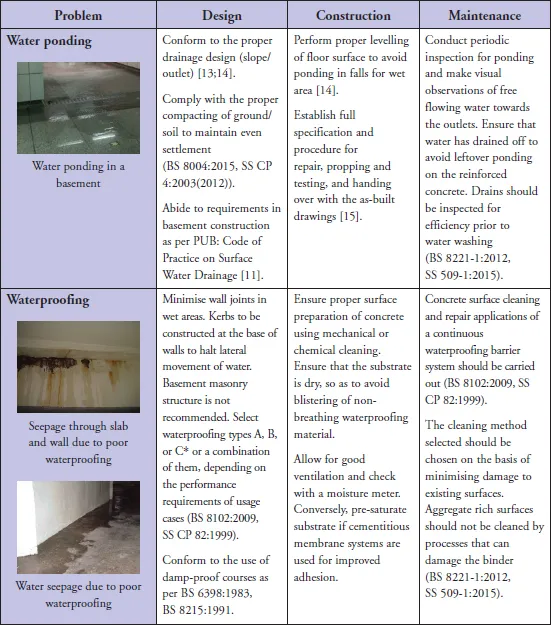

The utmost major problem in basements is the failure to attain water-tightness, though water seepage defects are common basement problems. Defects usually surface at a later stage due to changes in environmental conditions such as rising ground water, sump effect of excavation, differential settlement, etc. Basements also suffer from poor design, construction or maintenance of non-basement ancillary elements, such as a planter box or swimming pool at plaza level. The correct design, construction and maintenance practices for basements will help inhibit prevalent defects while ensuring efficient buildings with high maintainability. Important guidelines for the design, construction and maintenance of basements are highlighted in the succeeding tables, to address each corresponding basement defect. The identified structural defects refer to corrosion/spalling of concrete, seepage through porous concrete and cracks, and flood control. The identified architectural defects are concerned with construction joint installation, seepage through joints, water ponding and waterproofing issues, wall and flooring finishes. The identified service defects pertain to drainage and service penetration issues. Fire protection guidelines are also provided as a relevant requirement for basement areas.

The water-tightness of a basement depends mostly on the waterproofing design detailing which includes the waterproofing’s capability over penetrations, projections and joints. Drainage design detailing is critical to inhibit water build-up behind basement walls and subsequent water seepage/leakage. Careful consideration is necessary to certify that the selected material is appropriate for the environment of the basement, and that it matches the other materials used, so as not to compromise the overall lifespan of the basement due to untimely failures of mismatched materials. Quality control during construction is also a critical issue [7] especially for basements. Basement construction requires special attention due to its exposure to hydrostatic pressure. Provision of waterstops and drainage details are common devices in managing seepage through a basement’s construction joints. Good workmanship and the thorough protection of an installed waterproofing membrane can augment the waterproofing’s useful life to a substantial extent. Proper curing of the waterproofing is also crucial to preventing excessive shrinkage and cracking which will eventually lead to water seepage. The major critical elements (e.g. RCC structure, positive waterproofing or waterstops) are often beyond regular inspection and maintenance. Defects pertaining to these elements demonstrate visible signs on internal finishes, thus the locating of any early signs of leakage or dampness during post occupancy period must be performed. The detrimental effect of these external factors (e.g. mild to extreme, based on hydrostatic pressure, concentration of sulphur or chloride, acidity, contaminant, gas, radioactive material, etc.) should be taken into consideration in the maintenance stage [8].

1.1Structural

The structural components of a building (e.g. foundation, floor, slab, walls, and other load bearing and non-load bearing components) require design, construction and maintenance specifications to prevent premature deterioration and to help maximise the basement’s performance. The basement’s design should adhere to prevailing industry standards relating to foundation construction, structural stability, fire resistance, etc., whereas the builders must abide by local regulations and design drawings and specifications to ensure good quality in construction.

1.2Architectural

Architectural components define the character of the building, which include the finishes, furnishings, and other elements that contribute to the building’s aesthetic value and liveability. The design, construction and maintenance specifications for a basement’s architectural components will ensure optimal performance and better quality workmanship of the building.

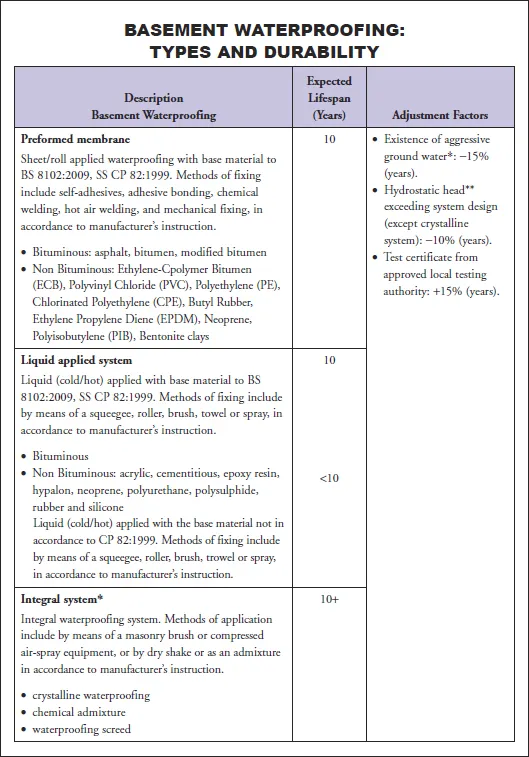

*CLASSIFICATION OF WATERPROOFING SYSTEMS [8]

Type A (Tanked Protection) — the structure itself does not prevent water ingress. Protection is dependent on a total water or water and vapour barrier system applied internally or externally.

Type B (Structurally Integral Protection) — refers to admixtures that are supposed to decrease the water permeability of structural concrete. This is not just a matter of concrete mix but also involves issues in structural design and the manner of handling of the concrete in the field. It can be applied by brush (as a coating), dry shake, or as an admixture.

Type C (Drained Protection) — the drained cavity wall and floor construction provides a high level of safeguard. Provision of a ventilated cavity and horizontal damp-proof membrane prevents moisture ingress.

1.3Services

Service co...