- 518 pages

- English

- ePUB (mobile friendly)

- Available on iOS & Android

Intensification of Biobased Processes

About this book

In recent years bioprocessing has increased in popularity and importance, however, bioprocessing still poses various important techno-economic and environmental challenges, such as product yields, excessive energy consumption for separations in highly watery systems, batch operation or the downstream processing bottlenecks in the production of biopharmaceutical products. Many of those challenges can be addressed by application of different process intensification technologies discussed in the present book.

The first book dedicated entirely to this area, Intensification of Biobased Processes provides a comprehensive overview of modern process intensification technologies used in bioprocessing. The book focusses on four different categories of biobased products: bio-fuels and platform chemicals; cosmeceuticals; food products; and polymers and advanced materials. It will cover various intensification aspects of the processes concerned, including (bio)reactor intensification; intensification of separation, recovery and formulation operations; and process integration. This is an invaluable source of information for researchers and industrialists working in chemical engineering, biotechnology and process engineering.

Frequently asked questions

- Essential is ideal for learners and professionals who enjoy exploring a wide range of subjects. Access the Essential Library with 800,000+ trusted titles and best-sellers across business, personal growth, and the humanities. Includes unlimited reading time and Standard Read Aloud voice.

- Complete: Perfect for advanced learners and researchers needing full, unrestricted access. Unlock 1.4M+ books across hundreds of subjects, including academic and specialized titles. The Complete Plan also includes advanced features like Premium Read Aloud and Research Assistant.

Please note we cannot support devices running on iOS 13 and Android 7 or earlier. Learn more about using the app.

Information

*Email: [email protected]

1.1 Introduction

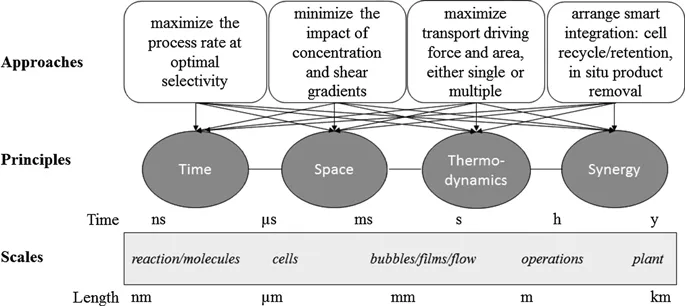

- Time – Improve kinetics: maximize the speed and effectiveness of molecular events.

- Space – Maximize homogeneity: create identical conditions for each molecule.

- Thermodynamics – Relieve transport limitations: such as maximize thermodynamic driving forces and transfer area.

- Synergy – Arrange smart integration: maximize the synergy between the separate parts.

1.2 Fermentation

1.2.1 Fermentation Processes

1.2.2 ...

Table of contents

- Cover

- Title Page

- Copyright Page

- Preface

- Contents

- Chapter 1 Intensified Fermentation Processes and Equipment

- Chapter 2 Rotating Bioreactors: Concept, Designs and Applications

- Chapter 3 Intensified Downstream Processing in Biofuels Production

- Chapter 4 Improving Fermentation by Product Removal

- Chapter 5 Liquid–Liquid Extraction in Processing of Bioproducts

- Chapter 6 Organic Solvent Nanofiltration for an Intensified Processing of Renewable Raw Materials

- Chapter 7 Green Fuels and Fuel Additives Production in Simulated Moving Bed Reactors

- Chapter 8 Intensification of Enzymatic Hydrolysis of Cellulose Using High Frequency Ultrasound

- Chapter 9 Process Intensification for Hydroprocessing of Vegetable Oil

- Chapter 10 Enzymatic Reactive Absorption and Distillation

- Chapter 11 Process Intensification of Immobilized Enzyme Reactors

- Chapter 12 Process Intensification of Enzymatic Biotransformation Processes

- Chapter 13 Microalgae: From Bio-based Curiosity Towards a Bulk Feedstock

- Chapter 14 Process Intensification in Glutamic Acid Production

- Chapter 15 Intensified Production of Recombinant Proteins

- Chapter 16 Intensification of Aqueous Two-phase Extraction for Protein Purification

- Chapter 17 Intensification of Functional Foods Production

- Chapter 18 Microwave-enhanced Extraction of Natural and Food Products: from Academia to Innovative and Large-scale Applications

- Chapter 19 Intensified Food Processing Through Membrane Operations

- Chapter 20 Intensified Brewing Systems

- Chapter 21 Novel Processing Concepts for Making Fibrous Food Products

- Chapter 22 The Usefulness of Direct Digital Manufacturing for Biomedical Applications

- Chapter 23 Alternative Energy Forms in Manufacturing, Processing and Applications of Biopolymers and Biomaterials

- Subject Index