- 284 pages

- English

- ePUB (mobile friendly)

- Available on iOS & Android

eBook - ePub

About this book

This book systematically introduces modeling, performance evaluation and applications of Automatic Materiel Handling System (AMHS) in semiconductor manufactucing, and focuses discussion on the coordination of two subsystems. Resources dispatch and optimization are conducted on operational research combined with cases studies. Written in a practical way, it is an essential reference for researchers and engineers in manufacturing and management.

Tools to learn more effectively

Saving Books

Keyword Search

Annotating Text

Listen to it instead

Information

1Semiconductor wafer fabrication system

1.1Semiconductor Manufacturing Industry

In the twenty-first century, modern technology experienced rapid development, especially the extensive application of electronic technology, which marked the human society entering the information age. In this “new economy” era, the information industry has become one of the largest and fastest growing industries in the world’s economy. Information and Internet technologies have a revolutionary impact on human economic and social life, while the semiconductor industry is its foundation. Integrated circuits (IC), microwave devices and optoelectronic devices made by semiconductor materials are the core products of the electronics industry and the information industry. They have been widely applied in people’s daily lives and exist all over the world. They have infiltrated into digital entertainment, mobile communications, e-commerce, automotive industry, medical equipment, aerospace and so on. In fact, every step of human society’s development nowadays is dependent on semiconductor chip technology. It can be said that the country that owns the semiconductor manufacturing industry will embrace the future of the world [1].

1.1.1Development and Current Status of the Semiconductor Manufacturing Industry

The semiconductor manufacturing industry is developed on the basis of vacuum tube electronics, radio communications and solid physical technology that emerged in the first half of the twentieth century. After World War II, scientists at Bell Telephone Laboratory began to study the solid-state silicon and germanium semiconductor devices. In 1947, they invented the first solid-state transistor, which led to the solid materials and technology-based modern semiconductor industry. Robert Nois in Fairchild Semiconductor and Jack Kilby in Texas Instruments independently invented the IC in 1959. The concept of an IC is intended to interconnect different components on planar silicon. This concept motivates engineers to design more sophisticated electronic circuits to meet customers’ new demands [2].

With the development of science and integrated technology, the carrier of ICs moved from the era of ordinary silicon material into the wafer era. Semiconductor chips are manufactured through a number of processes in the wafer to create a large number of complementary metal oxide semiconductor components that are connected with a metal wire to become a chip with logic function or storage function.

Manufacturing processes are becoming increasingly complex; meanwhile, the semiconductor manufacturing machine costs and semiconductor manufacturing plant construction costs are increasing. More European and American companies have moved out of the semiconductor manufacturing field and focused on design. Semiconductor manufacturing industry enterprises can be classified into three major classes: semiconductor equipment suppliers, semiconductor design company (fabless mode) and semiconductor manufacturing company (foundry mode). Of course, there are some companies, such as Intel Corporation, which set up their own manufacturing plants to produce advanced chips in order to protect the key technology of semiconductor chips. For this kind of manufacturers, its manufacturing process is at least one generation ahead of the manufacturing process of a professional pure semiconductor factory.

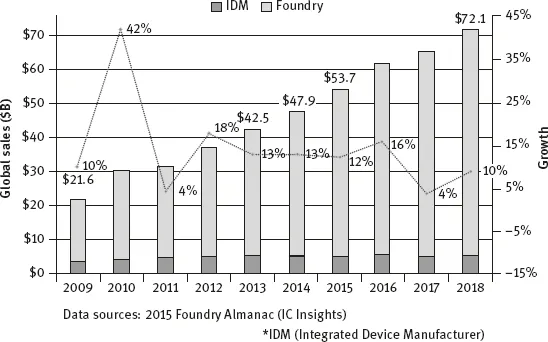

Figure 1.1: Forecast of sales and growth rates for global foundries (2015–2018).

Wafer manufacturing is the core and foundation of the semiconductor IC industry, which has shown a positive growth trend for a very long time. The Global Semiconductor Consortium (GSA) and the market research firm IC Insights jointly conducted a survey to study the growth trend in the industry. The survey report indicated that the percentage of ICs manufactured by wafer foundries in the entire chip market increased from 21% in 2004 to 24% in 2009 and jumped to 37% in 2014. This suggests that the semiconductor industry is transitioning from Integrated Device Manufacturers (IDM) to fab-site or fabless plant-based models, which is currently in the steep part of the industrial life cycle S-curve. GSA and IC Insights expect sales of ICs manufactured by foundries to approach 46% of total industry sales in 2018. Figure 1.1 shows the forecast of sales and growth rates for the global foundries in 2015–2018. Encouraged by demand, foundry companies are also gradually expanding their capacities, and actively developing to become super-factory (MegaFab) models. According to industry consensus, the so-called super factory refers to a 12-inch wafer factory with the monthly production capacity of 100,000–15 million and the amount of $70–$80 billion investment.

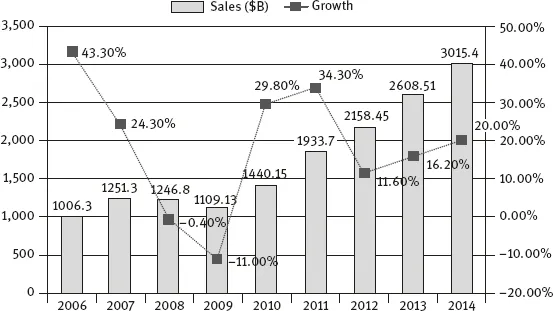

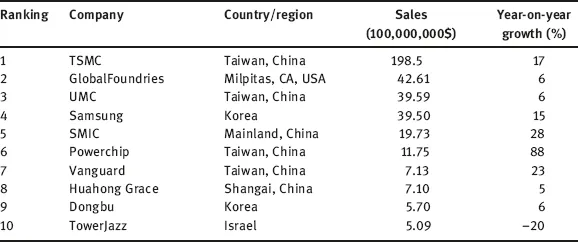

Semiconductor ICs are applied in almost all electronic equipment. Because of its strong promoting role and large multiplier effect, it is of great significance to computers, household appliances, digital electronics, automation, communications, aerospace and other industries. According to the China Semiconductor Industry Association statistics in 2010–2014, semiconductor IC industry sales in China maintained a double-digit, high growth rate. The proportion of GDP is increasing, as shown in Figure 1.2. Sales revenue data of 2015 must be available now. At present, the output value of the information industry in developed countries occupies 40–60% of the total output value of their national economy, and 65% of the GDP growth is related to the IC industry. Therefore, we can seize the initiative of the national economic development by further developing the IC industry. The semiconductor IC industry in China is also rapidly developing. China has developed a number of highly competitive enterprises including SMIC and Huahong Grace, which have entered the global top ten foundry business (shown in Table 1.1).

Figure 1.2: IC industry sales in China (2006–2014).

Table 1.1: The global foundry business ranking (2013).

1.1.2Future Challenges in the Semiconductor Manufacturing Industry

In the past half century, the semiconductor industry has undergone tremendous changes. In the coming two decades, the semiconductor industry will continue to face dramatic changes and challenges. Three aspects are presented as follows [3]:

1. Technological change is accelerating

The semiconductor chip industry began to develop rapidly in 1960, and the smallest feature size of the IC has been drastically reduced in less than 60 years. The size of the chip reduced from 50 μm in 1960 to 0.18 μm in the early twenty-first century. Up to now, the 40 nm IC has been very stable in the market. The 28 nm IC has also officially entered mass production and now it seems to have evolved to 22 nm, 16 nm and even more fine scale. At present, the 22 nm technology in Intel (the world’s most advanced technology company) has entered mass production (leading industry one–two years); 14 nm process is also mature. Rapid technological change leads to the emergence of new products and shortens products’ life cycles. Therefore, the primary challenge of semiconductor manufacturers is to achieve the maximum profit in the increasingly shortened product life cycle by shortening the manufacturing cycle and reducing production costs at a molar speed.

The semiconductor chip industry began to develop rapidly in 1960, and the smallest feature size of the IC has been drastically reduced in less than 60 years. The size of the chip reduced from 50 μm in 1960 to 0.18 μm in the early twenty-first century. Up to now, the 40 nm IC has been very stable in the market. The 28 nm IC has also officially entered mass production and now it seems to have evolved to 22 nm, 16 nm and even more fine scale. At present, the 22 nm technology in Intel (the world’s most advanced technology company) has entered mass production (leading industry one–two years); 14 nm process is also mature. Rapid technological change leads to the emergence of new products and shortens products’ life cycles. Therefore, the primary challenge of semiconductor manufacturers is to achieve the maximum profit in the increasingly shortened product life cycle by shortening the manufacturing cycle and reducing production costs at a molar speed.

2. The size of the semiconductor chip manufacturing industry needs to be expanded As the cost of developing and implementing next-generation processes is increasing rapidly, leading companies in the industry must be the forefront of semiconductor process development, and only large companies can afford these costs. Based on this, the acquisition of wafer industry has become the focus of the industry since 2008. Tower Semiconductor Ltd acquired Jazz Semiconductor Inc. in 2008. Global Foundries acquired Chartered Semiconductor in 2009, and became the second largest wafer foundry. NEC and Manulife Semiconductor (leading chipmakers in Japan) have also merged in 2010. This wave of mergers and acquisitions has also affected China. Therefore, the important development trend of the future semiconductor manufacturing industry is to enhance its scale.

3. Diversification of market demand

The dependence on and demand for digital electronic products in modern society will continue to rise rapidly in terms of quantity, quality and diversity. Technological innovation shortens the life cycles of semiconductor products, and fierce market competition reduces the profit in the semiconductor chip unit. In the shortest possible time, enterprises have to meet the dynamic demands of market diversification to produce a large number of new high-quality products to meet customer requirements and to quickly seize the market in order to earn the maximum profits. Therefore, one of the major challenges of semiconductor manufacturing enterprises is to effectively integrate internal and external resources in order to use the cost of less varictics and mass production to meet the demand of multi-species and mass production.

The dependence on and demand for digital electronic products in modern society will continue to rise rapidly in terms of quantity, quality and diversity. Technological innovation shortens the life cycles of semiconductor products, and fierce market competition reduces the profit in the semiconductor chip unit. In the shortest possible time, enterprises have to meet the dynamic demands of market diversification to produce a large number of new high-quality products to meet customer requirements and to quickly seize the market in order to earn the maximum profits. Therefore, one of the major challenges of semiconductor manufacturing enterprises is to effectively integrate internal and external resources in order to use the cost of less varictics and mass production to meet the demand of multi-species and mass production.

The development of the semiconductor industry is of great strategic signifi-cance in China; however, it is still in its early stages and faces challenges in technical expertise and has deficiencies in management. The most effective way to grow in the field would be to explore the development path by combining technology and management, which would actively promote the development of the semiconductor industry in China.

1.2Processing of Semiconductor Chips

The entire semiconductor chip manufacturing process consists of five phases: wafer preparation, wafer fabrication, wafer sort, chip packaging and chip final measurement. Among them, wafer fabrication and wafer sort are incorporated as “front-end operations”; chip packaging and chip final measurement are referred to as “back-end operations” (shown in Figure 1.3) [4].

In a semiconductor wafer fabrication system (SWFS), dozens or hundreds of specific IC chips are fabricated on a wafer with silicon as a substrate. The operational risks involved include a large number of workloads, large quantities of expensive processing machines and production steps, and a high degree of re-entrant flows.

1.2.1Wafer Preparation

Silicon is the main semiconductor material used to make IC chips and the most important material in the semiconductor industry. High-purity silicon used to make the chip is called semiconductor-grade silicon; sometimes, it is referred to as electronic-grade silicon [4]. The basis of wafer preparation is to convert a polycrystalline semiconductor-grade silicon block to a large single-crystal silicon, called a silicon ingot. The head and tail of the monocrystalline silicon rod are cut off and then the rod is mechanically trimmed to the appropriate diameter in order to obtain a “silicon rod” with a suitable diameter and a certain length. Since the silicon is very hard, a diamond saw is used to cut the silicon rod into wafer thin slices of equal thickness. The wafer is then ground in order to reduce the saw marks and damage to the front and back surfaces of the wafer and to thin the wafer. This process is called milling, after which the wafer is cleaned using chemicals, (i.e. sodium hydroxide, acetic acid and nitric acid to clean the surface of the wafer) in order to reduce damage and cracks generated during grinding. Thereafter, in the chamferin...

Table of contents

- Cover

- Title Page

- Copyright

- Contents

- 1 Semiconductor wafer fabrication system

- 2 Automated material handling systems in SWFSs

- 3 Modeling methods of automated material handling systems in SWFSs

- 4 Analysis of automated material handling systems in SWFSs

- 5 Scheduling methods of automated material handling systems in SWFSs

- 6 Scheduling in Interbay automated material handling systems

- 7 Scheduling in Intrabay automatic material handling systems

- 8 Integrated scheduling in AMHSs

- 9 Scheduling Performance Evaluation of Automated Material Handling Systems in SWFSs

- Index

Frequently asked questions

Yes, you can cancel anytime from the Subscription tab in your account settings on the Perlego website. Your subscription will stay active until the end of your current billing period. Learn how to cancel your subscription

No, books cannot be downloaded as external files, such as PDFs, for use outside of Perlego. However, you can download books within the Perlego app for offline reading on mobile or tablet. Learn how to download books offline

Perlego offers two plans: Essential and Complete

- Essential is ideal for learners and professionals who enjoy exploring a wide range of subjects. Access the Essential Library with 800,000+ trusted titles and best-sellers across business, personal growth, and the humanities. Includes unlimited reading time and Standard Read Aloud voice.

- Complete: Perfect for advanced learners and researchers needing full, unrestricted access. Unlock 1.4M+ books across hundreds of subjects, including academic and specialized titles. The Complete Plan also includes advanced features like Premium Read Aloud and Research Assistant.

We are an online textbook subscription service, where you can get access to an entire online library for less than the price of a single book per month. With over 1 million books across 990+ topics, we’ve got you covered! Learn about our mission

Look out for the read-aloud symbol on your next book to see if you can listen to it. The read-aloud tool reads text aloud for you, highlighting the text as it is being read. You can pause it, speed it up and slow it down. Learn more about Read Aloud

Yes! You can use the Perlego app on both iOS and Android devices to read anytime, anywhere — even offline. Perfect for commutes or when you’re on the go.

Please note we cannot support devices running on iOS 13 and Android 7 or earlier. Learn more about using the app

Please note we cannot support devices running on iOS 13 and Android 7 or earlier. Learn more about using the app

Yes, you can access Wafer Fabrication by Jie Zhang in PDF and/or ePUB format, as well as other popular books in Technology & Engineering & Civil Engineering. We have over one million books available in our catalogue for you to explore.