- 221 pages

- English

- ePUB (mobile friendly)

- Available on iOS & Android

About this book

Industrial Polymer Applications provides a comprehensive overview of the diverse properties and applications of thermoset and thermoplastic polymer technologies used routinely in the modification, protection, repair, restoration and bonding of the main classes of industrial engineering materials such as concrete, masonry, wood, metal, rubber, plastic, glass and advanced ceramics.

The Author, with extensive industrial experience in the design and development of polymeric adhesives, composites, concrete repair and industrial coatings materials, provides a balanced perspective of the essential chemistries and technologies for each of the relevant polymeric solutions. This book includes explanations as to why polymers are needed and the specific problems and key industrial application challenges that can be overcome for each class of engineering material. The use of supplementary information boxes, suggestions for further reading, and supportive appendices including worked examples delivers an easy to understand guide of relevant industrial applications of polymers.

Written in an accessible way, the book provides a supplementary text for undergraduates, postgraduates and industrialists who have studied or are involved in chemistry, polymer chemistry, industrial chemistry, materials science, chemical engineering, mechanical engineering, civil engineering or corrosion engineering, science and technology.

Frequently asked questions

- Essential is ideal for learners and professionals who enjoy exploring a wide range of subjects. Access the Essential Library with 800,000+ trusted titles and best-sellers across business, personal growth, and the humanities. Includes unlimited reading time and Standard Read Aloud voice.

- Complete: Perfect for advanced learners and researchers needing full, unrestricted access. Unlock 1.4M+ books across hundreds of subjects, including academic and specialized titles. The Complete Plan also includes advanced features like Premium Read Aloud and Research Assistant.

Please note we cannot support devices running on iOS 13 and Android 7 or earlier. Learn more about using the app.

Information

1.1 Introduction to Concrete and the Need for Modification, Repair and Protection

Fact File: Portland Cement

- Type I – general use cements when the special properties specified for the other types are not required;

- Type IA – air-entraining cement for the same uses as Type I, where air-entrainment is desired;

- Type II – for general use, more especially when moderate sulfate resistance is desired;

- Type IIA – air-entraining cement for the same uses as Type II, where air-entrainment is desired;

- Type II(MH) – for general use, more especially when moderate heat of hydration and moderate sulfate resistance are desired;

- Type II(MH)A – air-entraining cement for the same uses as Type II(MH), where air-entrainment is desired;

- Type III – for use when high early strength is desired;

- Type IIIA – air-entraining cement for the same use as Type III, where air-entrainment is desired;

- Type IV – for use when a low heat of hydration is desired;

- Type V – for use when high sulfate resistance is desired.

Fact File: Concrete Reinforcement

Application Challenge – Concrete Carbonation

Recommended Reading

- M. Neville, Properties of Concrete, John Wiley & Sons Inc., 5th edn, 2012, ISBN-13: 9780273755807.

- N. B. Winter, Understanding Cement, WHD Microanalysis Consultants Ltd., 2012, ISBN-13: 9780957104525.

- M. Raupach and T. Büttner, Concrete Repair to EN 1504: Diagnosis, Design, Principles and Practice, CRC Press, 2014, ISBN: 9781466557468.

- Concrete Repair: A Practical Guide, ed. M. G. Grantham, CRC Press, UK, 2014, ISBN: 9780415447348.

- M. H. Irfan, Chemistry and Technology of Thermosetting Polymers in Construction Applications, Springer Link, 1998, ISBN: 9789401060790.

1.2 Polymer-modified Cement Repair and Restoration

Fact File: Polymer-modified Levelling and Wearing Screeds

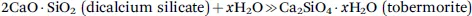

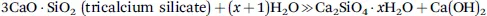

1.2.1 Essential Chemistry and Technology

Table of contents

- Cover

- Title

- Copyright

- Contents

- 1 Concrete Modification, Protection and Repair

- 2 Masonry and Wood Protection and Repair

- 3 Metal Protection and Repair

- 4 Rubber and Plastic Bonding, Repair and Restoration

- 5 Glass and Ceramics Repair and Bonding

- Appendix 1 Glossary of Resins, Polymers and Plastics

- Appendix 2 Thermoset Resin Stoichiometry Calculations

- Appendix 3 Cited International Standards, Practises, Specifications and Test Methods

- Subject Index