- 212 pages

- English

- ePUB (mobile friendly)

- Available on iOS & Android

eBook - ePub

Tyre Retreading

About this book

This book describes the different elastomers utilized in tyre retreading. Among others, it discusses reinforcing fillers in terms of their efficacy, the use of bonding agents, and their relevance to the tyre retreading process. The authors give specific guidelines for the practical compounding of different rubber compounds to make retread. A practical approach is also taken to describing the manufacturing technology used in tyre retreading.

Tools to learn more effectively

Saving Books

Keyword Search

Annotating Text

Listen to it instead

Information

Edition

1Subtopic

Industrial & Technical ChemistryBireswar Banerjee

1 Rubbers, compounding ingredients and their criterion in tyre retreading

1.1 Introduction

In the long history of automobile tyre manufacturing the following milestones are notable. In 1895, Michelin introduced its pneumatic automobile tyre. Previous to that, in 1888, Dunlop had patented the pneumatic tyre in the UK. Goodyear launched the first nylon-reinforced tyres in 1947 and, in the same year, BF Goodrich announced the tubeless tyre. Even more interestingly, in 1992 Michelin introduced the first durable ‘green tyres’, which were composed of rubber compounds reinforced with silica in place of the usual reinforcing agent carbon black.

In 1912, Marion Oliver patented a 10 ft and 12 ft long tread design, which was used in precure treads and marketed to other retreaders. In the 1980s, the tyre retreading business rapidly became globalised, and European companies began marketing equipment and manufacturing techniques in the USA. A new type of extruder was introduced to produce truck tyre retreading tread.

Also in the 1980s, a non-destructive method for the careful inspection of worn tyres was established. Then, in the 1990s, advancements began to be made in retreading using high-tech computerised devices. Technology for the primary inspection of worn tyres using an inflated inspection spreader and improved X-ray equipment has become available since then. Shearography, a new and improved off holography specially designed for the high-speed production and testing of tyres, can determine their viability for retreading. The inspection spreader device works by applying sufficient air pressure into a used tyre that any damaged sections of the casing become distorted, thereby allowing any defects to be identified easily.

The basic rubbers or elastomers used in compounding for tyre retreading purposes are high-molecular-weight (MW), amorphous, viscoelastic polymers with high elasticity. Rubber compounds prepared based on natural rubber (NR) with blends of synthetic elastomers such as polybutadiene rubber (PBR) and styrene-butadiene rubber (SBR) become soft and will flow during extrusion of the tread profile and moulding of the tread to give a flawless tread design with appropriate heat and graduations of stress during the moulding process.

For some special applications, tyre retread may require high weather, chemical, heat and oil resistance characteristics, which can be obtained by blending of NR, general purpose and special purpose synthetic rubbers [1].

The commonly used rubbers for tyre retreading applications are as follows:

- – NR (isoprene)

- – SBR

- – PBR

- – Chloroprene rubber (CR) for specific applications

- – Ethylene propylene diene monomer (EPDM) rubber for special applications (in blends with NR)

- – Reclaim rubber (as compounding ingredients)

An overview of the processing behaviour, physical/mechanical characteristics (such as hardness, tensile strength, modulus, abrasion, tear and flexing resistance), and chemical and oil resistance while operating in a particular environment is presented in this chapter. Technologists associated with the tyre retreading industry control rubber processing to determine the correct viscosity to function properly at a particular processing temperature, the rate of flow, applied stress and deformation, its rheological behaviour during extrusion for tread and on calendering for gum strips, and to obtain the correct blend of polymers to achieve the desired product characteristics.

The dispersion of carbon blacks, powdery chemicals, other inorganic fillers and so on, in the rubber matrix may require dispersing agents during the preparation of a compound to achieve good processing properties, lower energy costs (for mixing) and the ultimate desired effect for the finished materials. These may include wood rosin, synthetic resins, process oils, pine tars for high-carbon-black-filled compounds, and particular plasticisers for synthetic elastomers. Different kinds of process aid (PA) are used in rubber compounding to improve processability (e.g., fatty-acids, esters of fatty-acids, fatty-acid metal soaps, and low-MW resins).

At the initial stage of mixing a compound, high shear stress and high energy are necessary, but this can be significantly reduced using chemical peptisers, which reduce the viscosity of the basic NR via mechanical breakdown. This results in a reduction in energy consumption during mixing and improves the uniformity of the compound by increasing the efficiency of mixing. Some synthetic elastomers can also be treated with peptisers to reduce viscosity, but many can only be heat-treated during mixing before the incorporation of ingredients. Good processing and mixes with good physical properties are achievable when all the compounding ingredients are well dispersed, and a homogeneous compound is prepared for flawless processing.

Adhesion between the used/old tyres and the new tread is the most essential requirement of an elastomer compound, which must be strong enough and should provide the desired strength and durability during service [2].

1.2 Elemental criteria for the selection of rubbers for tyre retreading

The criteria for the selection of elastomers and additives to be processed for retreading are decisive in the choice of the right kind of rubber and the principal ingredients to meet the desired physical parameters. The essential properties considered are as follows:

- – Processing distinctiveness

- – Moulding and curing characteristics

- – Service condition and durability

- – Service temperature range

- – Duration of service

- – Bondability with old tyre

- – Physical properties such as mechanical strength, abrasion, cut and cut growth resistance

- – Resistance to water

- – Oil/chemical resistance (for specific uses)

- – Resistance to environmental degradation

- – Compound economics

1.3 Rubbers used for tyre retreading

1.3.1 Natural rubber

NR is the most widely used basic elastomer in all categories of the tyre retreading industry. NR has excellent mechanical and processing properties, with excellent green tack and adhesion characteristics with worn tyre. This rubber is largely used in truck tyres because of its road grip and low heat build-up properties.

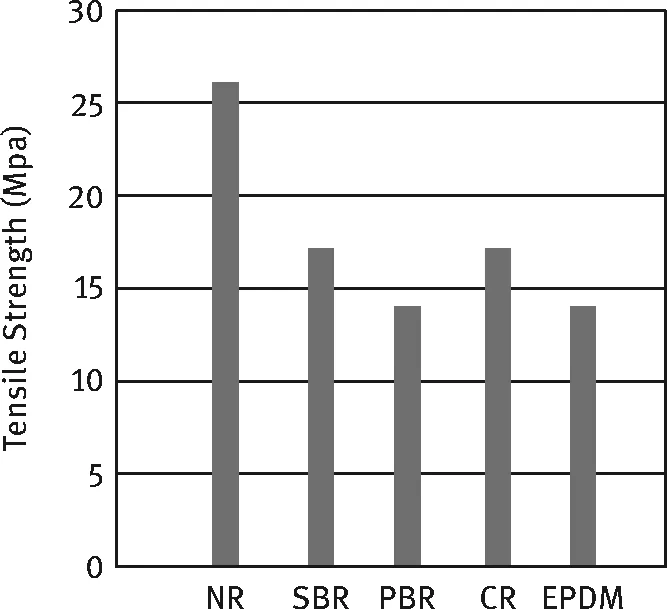

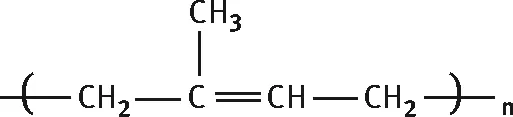

NR usually contains about 93% of NR (also simply termed hydrocarbon), plus certain inorganic salts and organic materials. The chemical name for NR is polyisoprene, polymer chains of which have the perfect cis-1,4 structures that give improved mechanical properties. The high gum tensile strength in this elastomer is due to crystallisation on stretching of its chain. When lower tensile strengths are demonstrated by elastomers that do not properly crystallise on stretching, rubber mixes with an adequate quantity of reinforcing materials are required to increase the tensile strengths. The tensile strengths of different rubbers that may be utilised for tyre retreading are illustrated in Figure 1.1.

NR can contain proteins, sugars, natural rosins and so on. In the grades of NR appropriate for use in tyre tread compounds, the acetone-soluble content must be in the range of 2.5–4.5%, nitrogen in the range 0.4–0.6%, with an ash content of 0.4%. A precise analysis of NR is provided in Table 1.1.

Table 1.1: Analysis of NR.

| Composition | Composition (%) |

|---|---|

| Rubber hydrocarbon | 93.3 |

| Protein | 2.8 |

| Acetone extracted matter | 2.9 |

| Ash | 0.4 |

| Moisture content | 0.6 |

1.3.1.1 Properties of natural rubber

NR is composed of polyisoprene chains with a cis-1,4 structure. NR with Mooney viscosities in the range of 60–75 Mooney units is suitable for use in tyre retreads.

A higher viscosity indicates a higher MW, leading to difficulties in processing during mixing, extrusion and calendering.

Having the correct viscosity of raw rubber is essential to making flawless extruded profiles for tyre tread and for the calendering process of tread gum and cushion gum sheeting. Achieving perfect processing behaviour depends predominantly on the viscosity and breakdown behaviour during mastication and mixing of the composition. To reduce complexity, blending of various rubbers from a stock of NR will solve the problem.

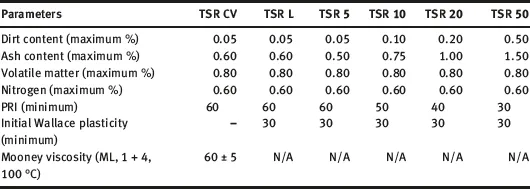

In order to control the variations in the quality of NR, several established approaches abide by the technical specifications framed by the International Organization for Standardization (ISO) in 1964 for the production of technically specified rubbers (TSR) such as standard Malaysian rubber (SMR), standard Indonesian rubber, standard Sri Lankan rubber, standard Thai rubber and Indian standard natural rubber. These standards provide the specific limits for dirt, ash, nitrogen, volatile matter and plasticity retention index (PRI), among others. A comprehensive specification for TSR is provided in Table 1.2.

Table 1.2: Specification for TSR.

Constant-viscosity (CV) NR (...

Table of contents

- Cover

- Title Page

- Copyright

- Contents

- Preface

- List of contributors

- 1 Rubbers, compounding ingredients and their criterion in tyre retreading

- 2 Processability, characterisation and properties of tyre retread compounding ingredients

- 3 Manufacturing technology for tyre retreading

- 4 Green tyre tread technology

- 5 Advances in tyre retreading and scope of run-flat tyres and elastomer nanocomposites

- 6 Testing and quality assurance for the tyre retreading industry

- Abbreviations

- Index

Frequently asked questions

Yes, you can cancel anytime from the Subscription tab in your account settings on the Perlego website. Your subscription will stay active until the end of your current billing period. Learn how to cancel your subscription

No, books cannot be downloaded as external files, such as PDFs, for use outside of Perlego. However, you can download books within the Perlego app for offline reading on mobile or tablet. Learn how to download books offline

Perlego offers two plans: Essential and Complete

- Essential is ideal for learners and professionals who enjoy exploring a wide range of subjects. Access the Essential Library with 800,000+ trusted titles and best-sellers across business, personal growth, and the humanities. Includes unlimited reading time and Standard Read Aloud voice.

- Complete: Perfect for advanced learners and researchers needing full, unrestricted access. Unlock 1.4M+ books across hundreds of subjects, including academic and specialized titles. The Complete Plan also includes advanced features like Premium Read Aloud and Research Assistant.

We are an online textbook subscription service, where you can get access to an entire online library for less than the price of a single book per month. With over 1 million books across 990+ topics, we’ve got you covered! Learn about our mission

Look out for the read-aloud symbol on your next book to see if you can listen to it. The read-aloud tool reads text aloud for you, highlighting the text as it is being read. You can pause it, speed it up and slow it down. Learn more about Read Aloud

Yes! You can use the Perlego app on both iOS and Android devices to read anytime, anywhere — even offline. Perfect for commutes or when you’re on the go.

Please note we cannot support devices running on iOS 13 and Android 7 or earlier. Learn more about using the app

Please note we cannot support devices running on iOS 13 and Android 7 or earlier. Learn more about using the app

Yes, you can access Tyre Retreading by Bireswar Banerjee in PDF and/or ePUB format, as well as other popular books in Technology & Engineering & Industrial & Technical Chemistry. We have over one million books available in our catalogue for you to explore.