eBook - ePub

Understanding Industry 4.0

AI, the Internet of Things, and the Future of Work

- 263 pages

- English

- ePUB (mobile friendly)

- Available on iOS & Android

eBook - ePub

Understanding Industry 4.0

AI, the Internet of Things, and the Future of Work

About this book

Everywhere you look, there are signs of the Fourth Industrial Revolution. R&D on leading digital technologies is conducted around the world, exploring novel technologies aimed at cyber-physical systems, such as the Internet of Things (IoT), Blockchain, 3D Printing, Virtual Reality, AI, and many more. With these rapid changes in technology comes social evolution and the potential for future social crises.

Understanding Industry 4.0: AI, the Internet of Things, and the Future of Work looks to determine the most probable oncoming changes in key areas of the economy, to highlight the most important professions of the future, and to offer recommendations for their correct selection and successful mastering. Including sections on careers in education, medicine, R&D, and agriculture, among others, economics experts Bruno S. Sergi, Elena G. Popkova, Aleksei V. Bogoviz, and Tatiana N. Litvinova explore the vastly changing modern workplace and offer a guide to navigating through and adapting to this evolution.

For researchers and students of management, economics, and business, this is an unmissable exploration of the new frontier of Industry 4.0.

Frequently asked questions

Yes, you can cancel anytime from the Subscription tab in your account settings on the Perlego website. Your subscription will stay active until the end of your current billing period. Learn how to cancel your subscription.

At the moment all of our mobile-responsive ePub books are available to download via the app. Most of our PDFs are also available to download and we're working on making the final remaining ones downloadable now. Learn more here.

Perlego offers two plans: Essential and Complete

- Essential is ideal for learners and professionals who enjoy exploring a wide range of subjects. Access the Essential Library with 800,000+ trusted titles and best-sellers across business, personal growth, and the humanities. Includes unlimited reading time and Standard Read Aloud voice.

- Complete: Perfect for advanced learners and researchers needing full, unrestricted access. Unlock 1.4M+ books across hundreds of subjects, including academic and specialized titles. The Complete Plan also includes advanced features like Premium Read Aloud and Research Assistant.

We are an online textbook subscription service, where you can get access to an entire online library for less than the price of a single book per month. With over 1 million books across 1000+ topics, we’ve got you covered! Learn more here.

Look out for the read-aloud symbol on your next book to see if you can listen to it. The read-aloud tool reads text aloud for you, highlighting the text as it is being read. You can pause it, speed it up and slow it down. Learn more here.

Yes! You can use the Perlego app on both iOS or Android devices to read anytime, anywhere — even offline. Perfect for commutes or when you’re on the go.

Please note we cannot support devices running on iOS 13 and Android 7 or earlier. Learn more about using the app.

Please note we cannot support devices running on iOS 13 and Android 7 or earlier. Learn more about using the app.

Yes, you can access Understanding Industry 4.0 by Bruno S. Sergi,Elena G. Popkova,Aleksei V. Bogoviz,Tatiana N. Litvinova in PDF and/or ePUB format, as well as other popular books in Negocios y empresa & Desarrollo empresarial. We have over one million books available in our catalogue for you to explore.

Information

Part I

Overview of Future Professions in Industry

Chapter 1

Outlines of the Context for Industry 4.0

1. Introduction

The modern global economy has entered the Fourth Industrial Revolution. Though it is at an early stage and breakthrough (revolutionary) digital technologies are still being developed and tested, the widespread interest in new technologies and the opportunities that they bring means that the leading economies are now fully embracing the transition to Industry 4.0. Germany was the first country to establish a national industrial strategy for Industry 4.0 in 2012, followed by the UK, which has adopted Industry 4.0 as the leading sphere of growth for industry and envisages “Eight great technologies”.

The United States proclaimed Industry 4.0 to be the critical tool for implementing its national strategy of innovational development. France has based its industrial reform program on the technologies of Industry 4.0 (Ministère de l’Economie et des Finances, 2015). Japan has determined Industry 4.0 as a top-priority in implementing its plan of scientific and technological modernization. The recently implemented initiatives of China for the development of industry through the application of technologies of Industry 4.0 and the creation of a digital economy based on the technologies of Industry 4.0 shows that the involvement of new and emerging markets in the Fourth Industrial Revolution and its truly global scale.

These national economic strategies and programs generally have a 2022–2025 time horizon. Therefore, the next five to seven years are likely to see the first transformation processes in global industry, and, in the next 10–15 years, radical transformations created by the technologies of Industry 4.0. These developments will make redundant current technologies (belonging to technological mode 3.0). The disruptions caused by the formation of Industry 4.0 in the next 10–15 years will completely change the structure of the global economy.

2. About the Transformation Processes

Number of employees rate in the industry according to OECD (2019) and share of industry in GDP according to World Bank (2019a, 2019b) are shown in Table 1.1 (as of 2018).

The data from Table 1.1 show the absence of visible interconnection between the number of employees and the level of development of industry in the leading countries as to manufacture of industrial products, their share in GDP (Top 10) as of 2018.

The data from Table 1.1 show the absence of a visible connection between the number of employees and the level of development of industry in the leading manufacturing countries and their share of global GDP (Top 10). The data also show a high unemployment rate in this industrial sector.

Table 1.1: Number of Employees in the Industry and Share of Industry in GDP (as of 2018).

Country | Employment in Industry (in Thousands) | Share of Industry in GDP |

Australia | 2,459 | 23.03 |

Austria | 1,062 | 25.27 |

Belgium | 964 | 19.75 |

Canada | 3,519 | 27.53 |

Chile | 1,882 | 29.96 |

Czech Republic | 1,987 | 33.46 |

Denmark | 525 | 19.86 |

Finland | 547 | 23.97 |

France | 5,435 | 17.36 |

Germany | 11,418 | 27.60 |

Greece | 575 | 14.79 |

Hungary | 1,394 | 26.44 |

Ireland | 412 | 19.66 |

Israel | 654 | 18.67 |

Italy | 5,986 | 21.36 |

Japan | 15,823 | 29.30 |

Korea | 6,602 | 35.87 |

Latvia | 21 | 19.52 |

Lithuania | 343 | 26.42 |

Luxembourg | 23 | 11.58 |

Mexico | 13,377 | 30.04 |

Netherlands | 1,282 | 17.53 |

New Zealand | 532 | 20.44 |

Norway | 512 | 29.90 |

Poland | 5,180 | 28.93 |

Portugal | 1,177 | 19.41 |

Slovak Republic | 940 | 30.97 |

Slovenia | 317 | 28.77 |

Spain | 3,776 | 21.61 |

Sweden | 908 | 22.14 |

Switzerland | 928 | 25.17 |

Turkey | 7,483 | 29.16 |

United Kingdom | 5,796 | 18.57 |

United States | 28,849 | 18.88 |

Colombia | 4,306 | 26.64 |

Russian Federation | 19,480 | 30.05 |

Source: Compiled by the authors based on OECD (2019) and World Bank (2019a, 2019b).

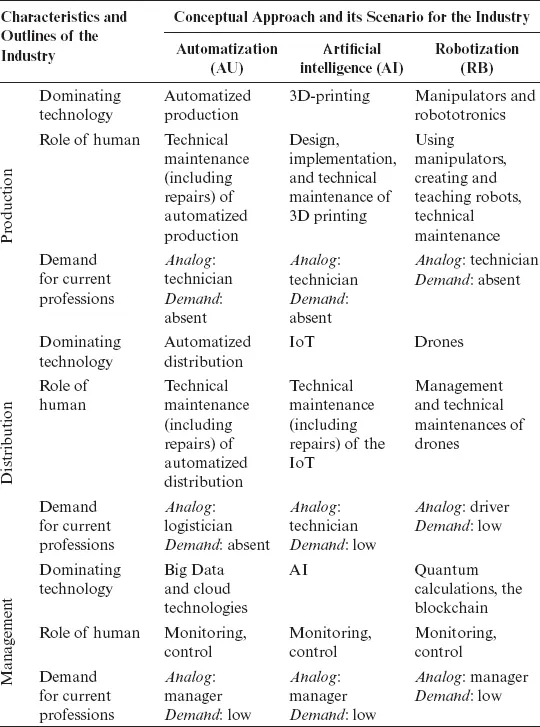

The importance of studying the transformation processes that are expected to take place in the context of the formation of Industry 4.0 is emphasized by the fact that this topic is already well studied. A content analysis of existing work and a systematization of accumulated scientific knowledge allowed us to perform classification of conceptual approaches to determining potential scenarios for the development of industry in the context of the formation of Industry 4.0 according to the criterion of dominating technologies. The comparative analysis and a description of these distinct approaches are given in Table 1.2.

As seen in Table 1.2, the first conceptual approach to determining scenarios for the development of industry in the context of the formation of Industry 4.0 envisages AU. During the organization of production, this means a full AU of the production process. At present, there are examples of fully automatized industrial production, for example, the car-maker Opel (Rüsselsheim, Germany). AU envisages preliminary programming by a human of separate production operations and their general sequence, as well as the further execution of these operations in a set sequence by an automatized production system.

The role of the human is reduced to technical maintenance (including diagnostics and repairs) of such an automated production system. The current worker who performs manual, mechanized, or partially automatized production will not be required within this future scenario.

With the organization of distribution, the future scenario envisages full AU (including logistics, supply, and sales). The role of the human will be reduced to technical maintenance (including diagnostics and repairs) in such an automated distribution system. The current professions of logistician and sales assistant, conducting manual or computerized roles in the logistical planning and sale of industrial products, will be in low demand in this future scenario.

Table 1.2: Scenarios for the Development of Industry in the Context of the Formation of Industry 4.0.

Source: Compiled by the authors.

The management of industrial production within this scenario, envisages the usage of Big Data technologies (technologies for the automatized processing of large arrays of data) and cloud technologies (technologies for storing information in the virtual environment, which reduces the risk of its loss during failures of hardware and software). The role of the human is reduced to monitoring and control over the work of these technologies. The real professions of the manager and HR manager will be in low demand in this future scenario. Further analysis of this scenario is presented in the works: Bogoviz (2019), Kuo, Ting, Chen, Yang, and Chen (2017), Moeuf, Pellerin, Lamouri, Tamayo-Giraldo, and Barbaray (2017), Popkova (2019), Popkova, Ragulina, and Bogoviz (2019), Bauer, Pokorni, and Findeisen (2019), Dostatni, Diakun, Grajewski, Wichniarek, and Karwasz (2019), Galvão et al. (2019), and Wrobel-Lachowska, Polak-Sopinska, and Wisniewski (2019).

The second conceptual approach to determining scenarios for the development of industry in the context of the formation of Industry 4.0 envisages the creation and distribution of AI. During the organization of production, this means the usage of 3D printing (three-dimensional printing). This technology allows for the rapid manufacturing of industrial products as single items with the help of 3D printers. This ensures the timely execution of individual orders, as there is no necessity for the automatized production process.

The role of the human in such a scenario is reduced to design, impl...

Table of contents

- Cover

- Title

- Part I. Overview of Future Professions in Industry

- Part II. Future Professions in Agriculture

- Part III. Future Professions in Medicine

- Part IV. Future Planned Professions in Education

- Part V. Expected Professions in Body Care and Fitness

- Part VI. The Key Future Professions in R&D

- Part VII. Perspectives on Future Professions in Transport and Communications

- Part VIII. Recommendations for Successful Modern Workers

- Conclusions

- List of Acronyms

- References

- Index