The Imperial College Lectures in Petroleum Engineering

Volume 4: Drilling and Reservoir Appraisal

- 396 pages

- English

- ePUB (mobile friendly)

- Available on iOS & Android

The Imperial College Lectures in Petroleum Engineering

Volume 4: Drilling and Reservoir Appraisal

About this book

This book covers the fundamentals of drilling and reservoir appraisal for petroleum. Split into three sections, the first looks at the basic principles of well engineering in terms of planning, design and construction. It then goes on to describe well safety, costs and operations management. The second section is focussed on drilling and core analysis, and the laboratory measurement of the physico-chemical properties of samples. It is clear that efficient development of hydrocarbon reservoirs is highly dependent on understanding these key properties, and the data can only be gathered through a carefully conducted core-analysis program, as described. Finally, in the third section we look at production logging, an essential part of reservoir appraisal, which describes the nature and the behaviour of fluids in or around the borehole. It describes how to know, at a given time, phase by phase, and zone by zone, how much fluid is coming out of or going into the formation.

As part of the Imperial College Lectures in Petroleum Engineering, and based on a lecture series on the same topic, Drilling and Reservoir Appraisal provides the introductory information needed for students of the earth sciences, petroleum engineering, engineering and geoscience.

Contents:

- Well Engineering (Michael Dyson)

- Core Analysis (Vural Sander Suicmez, Marcel Polikar, Xudong Jing and Christopher Pentland)

- Production Logging (Olivier Allain)

Readership: Students of the earth sciences, petroleum engineering, engineering and geoscience. Reservoirs;Oil-Well Drilling;Production Logging;Core Analysis;Well Operations;Hydrocarbon Reservoirs00

Frequently asked questions

- Essential is ideal for learners and professionals who enjoy exploring a wide range of subjects. Access the Essential Library with 800,000+ trusted titles and best-sellers across business, personal growth, and the humanities. Includes unlimited reading time and Standard Read Aloud voice.

- Complete: Perfect for advanced learners and researchers needing full, unrestricted access. Unlock 1.4M+ books across hundreds of subjects, including academic and specialized titles. The Complete Plan also includes advanced features like Premium Read Aloud and Research Assistant.

Please note we cannot support devices running on iOS 13 and Android 7 or earlier. Learn more about using the app.

Information

Chapter 1

Well Engineering

1.1.Introduction

1.1.1.Objectives

1.2.Health, Safety and Environment (HSE)

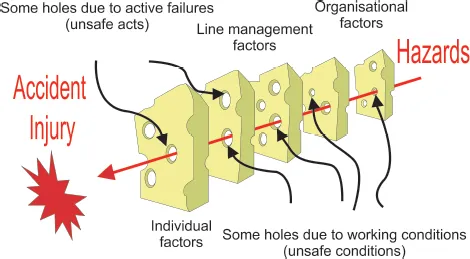

1.2.1.Accidents are not Accidental

1.2.2.Safety is Built-In

Table of contents

- Cover

- Halftitle

- Series Editors

- Title

- Copyright

- Foreword

- Preface

- About the Authors

- Chapter 1. Well Engineering

- Chapter 2. Core Analysis

- Chapter 3. Production Logging

- Index