eBook - ePub

Probabilistic Physics of Failure Approach to Reliability

Modeling, Accelerated Testing, Prognosis and Reliability Assessment

- English

- ePUB (mobile friendly)

- Available on iOS & Android

eBook - ePub

Probabilistic Physics of Failure Approach to Reliability

Modeling, Accelerated Testing, Prognosis and Reliability Assessment

About this book

The book presents highly technical approaches to the probabilistic physics of failure analysis and applications to accelerated life and degradation testing to reliability prediction and assessment. Beside reviewing a select set of important failure mechanisms, the book covers basic and advanced methods of performing accelerated life test and accelerated degradation tests and analyzing the test data. The book includes a large number of very useful examples to help readers understand complicated methods described. Finally, MATLAB, R and OpenBUGS computer scripts are provided and discussed to support complex computational probabilistic analyses introduced.

Tools to learn more effectively

Saving Books

Keyword Search

Annotating Text

Listen to it instead

Information

Edition

1Chapter 1

Overview of Probabilistic Physics-of-Failure Approach to Reliability

1.1. INTRODUCTION

To address risk and reliability challenges in design, manufacturing and operation, reliability engineering has gone through a number of transformations over the past few decades. Reliability methods have progressively become more realistic by incorporating both data and information from real causes, and the modeling of failure phenomena. The evolution of reliability modeling from constant hazard rates to more representative life distributions (such as the Weibull and lognormal) was the first step towards better addressing wear-out and aging failure mechanisms in structures, systems and components. This trend was followed by the use of physics and mechanistic principles, as well as thermodynamic laws. Accelerated testing has borrowed concepts from materials degradation and fracture mechanics, through which the aggregate effects of operational and environmental conditions were formally accounted for in the life models.

The formal consideration of physics and mechanistic methods in reliability engineering is referred to as a “physics of failure” (PoF) approach. The PoF approach is a science-based means to reliability engineering and prediction as well as prognosis and health management, in contrast to the traditional statistical approach that relies on historical data. It uses physics-based modeling and simulations to assess design and reliability. The approach can be used to evaluate and predict system performance while reducing subjectivities in reliability assessments by modeling failure mechanisms such as fatigue, fracture, wear, and corrosion. The PoF approach is a comprehensive representation of wear out and aging, and is capable of bringing relevant physical factors into the life assessment and reliability models of the structures, components and systems.

The development of PoF models is still typically based on limited information. The uncertainties associated with this limitation have led to a Probabilistic Physics of Failure (PPoF) approach that formally addresses and incorporates uncertainties about the PoF models and their outputs.

Physics and mechanistic-based failure models can be categorized into three core frameworks: stress-strength, damage-endurance, and performance-requirements. In all these PoF modeling frameworks, metrics representing failure-inducing agents such as applied loads and environmental attack properties should be identified. Mechanical, thermal, electrical, chemical, and radiation-induced forces can cause stresses on an item. The passage of time drives the accumulation of damage. Both load and time may either be analyzed deterministically (e.g., identifying and studying the sources of stresses) or probabilistically (e.g., treating stress variation as a random variable). Substantial uncertainties associated with failure-inducing agents can emanate from environmental and operating (use) conditions and from the emergence of failure mechanisms that were not considered or well understood at the time of design.

Because of cost and time limitations, great emphasis has been placed on capturing reliability information from field data with minimal effort. As a result, design and assessment methodologies that address failures mechanistically have emerged as popular and powerful cost saving techniques. Accelerated life testing (ALT), an approach to mechanistic modeling of wear-out, damage process and failure, is a direct outcome of this movement. Unlike the reliability models developed on the basis of field data that suffer from wide variation in operating conditions and practices, reliability models based on PoF, developed using accelerated life or degradation tests, take into account operational conditions (applied stresses) that permit flexibility in applied stresses, leading to more relevant models.

Before performing the accelerated test, a stress agent, which could be an aggregate effect of a single or multiple physical and operational conditions, should be identified. The next step involves accelerating this stress agent and applying it to samples of the structure, system or component in a test environment. Models of failure, damage and degradation are developed by using accelerated test data for a more flexible and representative description of the damage, failure phenomena, performance and life as compared to the traditional probabilistic approach to failure modeling.

Failure interdependency can also be a critical factor in reliability modeling of mechanical systems and components. In the study of system behavior, there are situations in which progressive failure of one component may activate or accelerate other failure mechanisms or the failure of other components. There are usually many links between different components by means of their properties and common environmental conditions. The PoF approach properly incorporates these interdependencies in complex structures, systems and components.

1.2. OVERVIEW OF PHYSICS-OF-FAILURE MODELING

Physics of failure modeling initially evolved out of examination of fatigue and fracture of materials. Reliability work related to fatigue and fracture of materials showed significant progress through the 1950s and early 1960s. In 1957, George R. Irwin proved that the fracture of materials was due to plastic deformation at the crack tip and generalized Griffith’s Theory (Irwin 1957) that described the relationship between applied nominal stress and crack length at fracture. Between 1955 and 1963, Waloddi Weibull produced several publications related to modeling of fatigue and creep mechanisms that also discussed evaluating associated data (Weibull 1959). In 1961, Weibull published a book on materials and fatigue testing while working as a consultant for the U.S. Air Force Materials Laboratory (Weibull 1961). Building on Irwin’s work on stress intensity factor, Paris et al. (Paris, Gomez and Anderson 1961) introduced methods for predicting the rate of fatigue crack growth.

Given this background in mechanistic-based life models (particularly to assess fatigue and fracture failures), Rome Air Development Center (RADC—the predecessor to the U.S. Air Force Rome Laboratory) introduced a PoF program in 1961 to address the growing complexity of military equipment and the consequent increase in number of failures observed. In 1962, researchers from Bell Labs published a paper on “High Stress Aging to Failure of Semiconductor Devices” that justified using the kinetic theory’s interpretation of the Arrhenius equation: a simple yet accurate formula for the temperature dependence of the reaction rate constant as a basis for assessment of temperature-induced aging of semiconductor devices (Dodson and Howard 1961). Later, the RADC and Armor Research Foundation of the Illinois Institute of Technology (now IIT Research Institute) organized the first PoF symposium in electronics in Chicago in September 1962. This symposium laid the groundwork for future research and development activities related to PoF by RADC and several other organizations. Numerous original papers and ideas introducing and explaining the PoF concepts and methods were presented in these symposia, which continue today in IEEE International Reliability Physics symposia and Reliability and Maintainability Symposia (RAMS).

The PoF approach to reliability utilized scientific knowledge of damage and degradation processes and the load profile applied to an item, its structure, material properties and environmental conditions to identify potential failure mechanisms that individually or in combination lead to the item’s failure. The PoF models would then be used to assess reliability, expended life and remaining life. Using PoF diminishes the need for enormous amounts of use-level life data and uses smaller sets of accelerated test data and other relevant data to present a more representative model. The PoF approach employs the available well-developed knowledge about the mechanisms of failure. The PoF models show how and why items fail, reducing the need for large (and expensive) quantities of life data.

The most critical step in a PoF approach is to understand failure mechanisms (such as corrosion or fatigue) in order to appropriately model degradation and time that a failure occurs. Accelerated life testing based on PoF models is an approach that can reduce long and costly life testing. In this approach, one seeks to relate the fundamental physical and chemical properties of materials to reliability metrics (such as degradation, life or cycles-to-failure). To eliminate (or reduce) the occurrence of failures, one must eliminate (or reduce) their root causes. To do that, one must also understand the physics of the material and failure mechanisms involved (Vaccaro 1962). Sometimes it is impossible to build several identical units or prototypes for reliability testing. Cases in point include large-scale systems (like buildings and space vehicles), one-of-a-kind or highly expensive systems, and units that must work properly at the first time. In these cases, performance and field data are not available, and a PoF approach to degradation and life assessment is the most appropriate. As such, the PoF approach is particularly useful in the design stage when there are limited prototypes or test facilities. Finally, the PoF approach has great utility when dealing with highly reliable units, when there is very little failure data to analyze.

PoF techniques can be used to interpret and extrapolate field data for failure prediction for in-service components. This field data might include parameters that are related to traditional physical measures but can only be used as a loose model for failure prediction. A good example of this is vibration of a bearing. The vibration is suggestive of a flaw, but since the flaw itself cannot be tracked, the vibration can be used to estimate failure. This obviously presents potential for high uncertainty because changes in the model cannot be easily detected; for example, there is no assurance that if a new flaw develops it would expedite the failure, so that it can be detected and incorporated into the model. However, this method at least presents some means of tracking the degradation of the component. This is useful for maintenance practitioners, as it provides a means of failure estimation when traditional methods cannot be used due to the lack of measurable PoF model parameters.

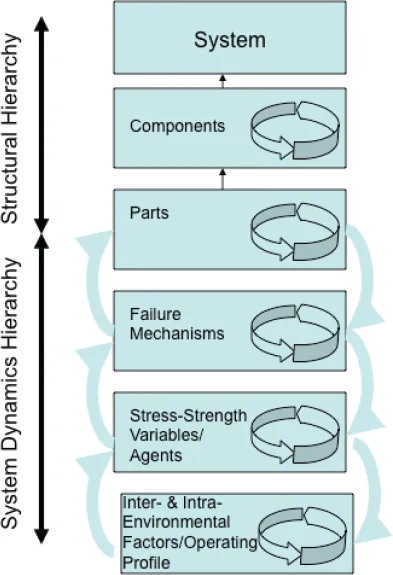

There is no single methodology for performing PoF-based reliability analysis. Chapter 2 discusses in more detail the steps involved in developing a PoF model of an item. If an item involves multiple subassemblies (parts and components), each subject to different failure mechanisms, then the combined effect of applicable failure mechanisms should be modeled. Figure 1.1 depicts the structural and dynamic hierarchy of PoF analysis elements for a multi-component system. The lowest level in this hierarchy is inter- and intra-environmental factors. The intra-environmental factors refer to conditions resultant from unit operation itself. This includes, for example, heat dissipation or vibration caused by an imbalanced rotating shaft. The inter-environmental factors are those imposed externally from its design boundary. Examples include relative humidity and prevalence of dust particles. There may be a causal chain among inter- and intra-environmental factors such that one may lead to another or vice versa in a synergistic manner. For example, a low temperature may cause condensation, leading to accelerated corrosion.

Figure 1.1: System hierarchy used in PoF analysis

All environmental factors potentially lead to various forms of stress. For example, high temperature (as either an inter- or intra-environment factor) leads to thermal expansion, and (if the unit is confined) can cause mechanical stresses. Such stress agents are key actors in activating or a...

Table of contents

- Cover

- Title page

- Copyright page

- Preface

- Chapter 1: Overview of Probabilistic Physics-of-Failure Approach to Reliability

- Chapter 2: Summary of Mechanisms of Failure and Associated PoF Models

- Chapter 3: Types of Accelerated Testing and Modeling Concepts

- Chapter 4: Analysis of Accelerated Life Testing Data and Physics-Based Reliability Model Development

- Chapter 5: Analysis of Accelerated Degradation Data and Reliability Model Development

- Chapter 6: Accelerated Test Planning

- Chapter 7: Accounting for Uncertainties and Model Validation

- Index

- End User License Agreement

Frequently asked questions

Yes, you can cancel anytime from the Subscription tab in your account settings on the Perlego website. Your subscription will stay active until the end of your current billing period. Learn how to cancel your subscription

No, books cannot be downloaded as external files, such as PDFs, for use outside of Perlego. However, you can download books within the Perlego app for offline reading on mobile or tablet. Learn how to download books offline

Perlego offers two plans: Essential and Complete

- Essential is ideal for learners and professionals who enjoy exploring a wide range of subjects. Access the Essential Library with 800,000+ trusted titles and best-sellers across business, personal growth, and the humanities. Includes unlimited reading time and Standard Read Aloud voice.

- Complete: Perfect for advanced learners and researchers needing full, unrestricted access. Unlock 1.4M+ books across hundreds of subjects, including academic and specialized titles. The Complete Plan also includes advanced features like Premium Read Aloud and Research Assistant.

We are an online textbook subscription service, where you can get access to an entire online library for less than the price of a single book per month. With over 1 million books across 990+ topics, we’ve got you covered! Learn about our mission

Look out for the read-aloud symbol on your next book to see if you can listen to it. The read-aloud tool reads text aloud for you, highlighting the text as it is being read. You can pause it, speed it up and slow it down. Learn more about Read Aloud

Yes! You can use the Perlego app on both iOS and Android devices to read anytime, anywhere — even offline. Perfect for commutes or when you’re on the go.

Please note we cannot support devices running on iOS 13 and Android 7 or earlier. Learn more about using the app

Please note we cannot support devices running on iOS 13 and Android 7 or earlier. Learn more about using the app

Yes, you can access Probabilistic Physics of Failure Approach to Reliability by Mohammad Modarres,Mehdi Amiri,Christopher Jackson in PDF and/or ePUB format, as well as other popular books in Technology & Engineering & Electrical Engineering & Telecommunications. We have over one million books available in our catalogue for you to explore.