Material Forming Processes

Simulation, Drawing, Hydroforming and Additive Manufacturing

- English

- ePUB (mobile friendly)

- Available on iOS & Android

Material Forming Processes

Simulation, Drawing, Hydroforming and Additive Manufacturing

About this book

Manufacturing industries strive to improve the quality and reliability of their products, while simultaneously reducing production costs. To do this, modernized work tools must be produced; this will enable a reduction in the duration of the product development cycle, optimization of product development procedures, and ultimately improvement in the productivity of design and manufacturing phases.

Numerical simulations of forming processes are used to this end, and in this book various methods and models for forming processes (including stamping, hydroforming and additive manufacturing) are presented. The theoretical and numerical advances of these processes involving large deformation mechanics on the basis of large transformations are explored, in addition to the various techniques for optimization and calculation of reliability.

The advances and techniques within this book will be of interest to professional engineers in the automotive, aerospace, defence and other industries, as well as graduates and undergraduates in these fields.

Tools to learn more effectively

Saving Books

Keyword Search

Annotating Text

Listen to it instead

Information

1

Forming Processes

1.1. Introduction

1.2. Different processes

- – smelting;

- – machining;

- – powder metallurgy;

- – hot or cold plastic strain forming.

- – the abilities of the material in relation to the different processes (particular attention should be given to the difference between a foundry alloy and alloys deemed “wrought”) regarding the form and the dimension of the product;

- – the defined metallurgical health (limitation of defects such as cracks, porosities and chemical segregations);

- – the usage properties of the product in the mechanical field;

- – the desired surface condition (in terms of cleanliness, roughness, of residual stresses, etc.).

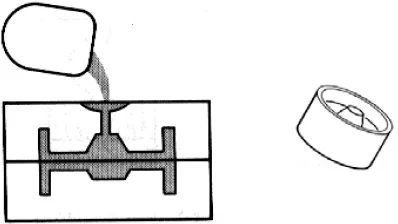

1.2.1. Smelting

- – The mold is made up of sand and inside it a cavity can be found that will represent the resulting piece. The first operation consists of building a pattern generating the shape of the desired casting by integrating the machining allowances and the useful drafts. The pattern represents the mold cavity left in the sand when the mold is closed. The mold is opened to extract the pattern therefrom and closed to the molten metal. When solidification is achieved after slow cooling, the mold is broken in order to retrieve the final product. One casting is thus obtained per mold.

- – The mold is in metal and thus is reusable. The cooling proves to be much faster than the sand casting process. The pattern is obtained by machining the mass and with respect to the hollow parts, they can be achieved with eventually destructible cores.

- – Die-casting integrates a metal mold but the filling of the pattern is ensured by means of a piston that pushes the liquid at high speed in a short period of time (a few 1/10 of a second). A slight overpressure can be maintained in the mold, which has the effect of properly feeding the pattern, while avoiding the design of a hot-top to perform this function. The mechanization of the process is total. On the other hand, the tools undergo very significant repeated efforts, which reduces their life expectancy (20,000–50,000 parts depending on the nature of the cast alloy).

- – Centrifugal casting concerns all so-called revolution parts. The fundamental difference lies at the level of the introduction of liquid material, which is carried out along an axis around which the mold revolves. The centrifugal force promotes uniform filling. The structural composition is finer and full.

1.2.2. Machining

- – Chip formation: Machining takes place following optimized cutting conditions, which consider the geometry of the cutting tool, the cutting fluid and the dimension of the non-deformed chip. It is formed following primary shearing of the metal when making contact with the cutting edge of the tool and following a secondary shear when in contact with the external edge of the tool. This effort zone undergoes superficial strain hardening and heating. In addition, the chip is subjected to the same efforts coupled to the tool on its external edge. Futhermore, the cutting speed Vc plays a paramount role and is thus expressed:

- – The machined surface: It is defined by a heated and hard-tempered underlying superficial area. The microstructure can therefore be modified (constituents or phase change) or even undergo local strain hardening by cold working. Often, there remains a significant local residual stress field. Moreover, microcracks can be observed.

- – The chip: When the material is fragile, it quickly becomes fragmented into lemels (for example some smeltings). In the event that it is ductile and slightly consolidates. However, when this consolidation occurs as a result of the hardening phenomenon, it easily fragments. On the other hand, a few obstacles to chip formation may surge notably due to heating and pressure. A galling phenomenon can be observed between tool and chip forming a bui...

Table of contents

- Cover

- Table of Contents

- Title

- Copyright

- Preface

- 1 Forming Processes

- 2 Contact and Large Deformation Mechanics

- 3 Stamping

- 4 Hydroforming

- 5 Additive Manufacturing

- 6 Optimization and Reliability in Forming

- 7 Application of Metamodels to Hydroforming

- 8 Parameters Identification in Metal Forming

- Appendices

- Bibliography

- Index

- End User License Agreement

Frequently asked questions

- Essential is ideal for learners and professionals who enjoy exploring a wide range of subjects. Access the Essential Library with 800,000+ trusted titles and best-sellers across business, personal growth, and the humanities. Includes unlimited reading time and Standard Read Aloud voice.

- Complete: Perfect for advanced learners and researchers needing full, unrestricted access. Unlock 1.4M+ books across hundreds of subjects, including academic and specialized titles. The Complete Plan also includes advanced features like Premium Read Aloud and Research Assistant.

Please note we cannot support devices running on iOS 13 and Android 7 or earlier. Learn more about using the app