Common Rail Fuel Injection Technology in Diesel Engines

- English

- ePUB (mobile friendly)

- Available on iOS & Android

Common Rail Fuel Injection Technology in Diesel Engines

About this book

A wide-ranging and practical handbook that offers comprehensive treatment of high-pressure common rail technology for students and professionals

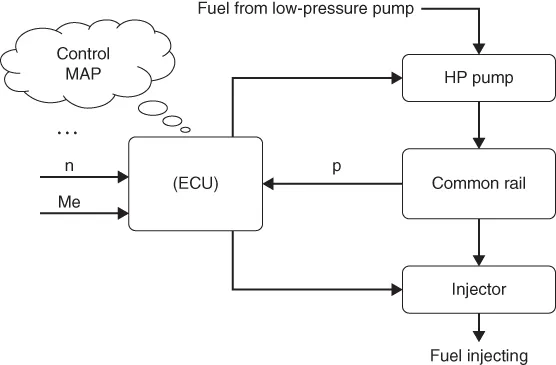

In this volume, Dr. Ouyang and his colleagues answer the need for a comprehensive examination of high-pressure common rail systems for electronic fuel injection technology, a crucial element in the optimization of diesel engine efficiency and emissions. The text begins with an overview of common rail systems today, including a look back at their progress since the 1970s and an examination of recent advances in the field. It then provides a thorough grounding in the design and assembly of common rail systems with an emphasis on key aspects of their design and assembly as well as notable technological innovations. This includes discussion of advancements in dual pressure common rail systems and the increasingly influential role of Electronic Control Unit (ECU) technology in fuel injector systems. The authors conclude with a look towards the development of a new type of common rail system. Throughout the volume, concepts are illustrated using extensive research, experimental studies and simulations. Topics covered include:

- Comprehensive detailing of common rail system elements, elementary enough for newcomers and thorough enough to act as a useful reference for professionals

- Basic and simulation models of common rail systems, including extensive instruction on performing simulations and analyzing key performance parameters

- Examination of the design and testing of next-generation twin common rail systems, including applications for marine diesel engines

- Discussion of current trends in industry research as well as areas requiring further study

Common Rail Fuel Injection Technology is the ideal handbook for students and professionals working in advanced automotive engineering, particularly researchers and engineers focused on the design of internal combustion engines and advanced fuel injection technology. Wide-ranging research and ample examples of practical applications will make this a valuable resource both in education and private industry.

Frequently asked questions

- Essential is ideal for learners and professionals who enjoy exploring a wide range of subjects. Access the Essential Library with 800,000+ trusted titles and best-sellers across business, personal growth, and the humanities. Includes unlimited reading time and Standard Read Aloud voice.

- Complete: Perfect for advanced learners and researchers needing full, unrestricted access. Unlock 1.4M+ books across hundreds of subjects, including academic and specialized titles. The Complete Plan also includes advanced features like Premium Read Aloud and Research Assistant.

Please note we cannot support devices running on iOS 13 and Android 7 or earlier. Learn more about using the app.

Information

1

Introduction

- (1) The degree of control freedom increases. The electronic control fuel injection system can optimize comprehensive control on the injection parameters in accordance with the different operating conditions.

- (2) The control precision improves. For instance, the injection timing control accuracy (CA) is higher than 0.5° CA and the accuracy is four times higher than with mechanical control.

- (3) Since the diesel engine fuel injection system has the characteristics of high voltage and high frequency and pulse, it will be able to achieve these objectives and will certainly bring about the complexity of actuator and control and strict requirements on reliability and duration of system that are required.

1.1 The Development of an Electronic Control Fuel Injection System

1.1.1 Position Type Electronic Control Fuel Injection System

| Form | System name | Control characteristics |

| S T | ||

| Pump Zexel (Japan) COPEC | High‐speed solenoid valve control injection time, variable inductance displacement control fuel injection quantity | |

| R A | BOSCH (Germany company) EDR | High‐speed solenoid valve control gear lever displacement, adjustable CAM phase |

| I G | (American Caterpillar company) PEEC – ECD‐P3 | Brushless torque motor control gear lever displacement, linear potentiometer control injection time |

| H | (Japan Toyota) ECD‐p | High‐speed solenoid valve control injection time, adjustable CAM phase |

| T | BOSCH (Germany company) TICS | High‐speed solenoid valve control plunger sleeve and gear lever position, the variable stroke |

| C | (Japan Toyota) ECD‐p | High‐speed solenoid valve control injection time, adjustable CAM phase |

| O | (British Lucas) EPIC | The phase of the CAM ring to control injection timing, control the distribution of rotor axial displacement control of oil |

| L U | (Stanadyne companies in the United States) PCF | Control CAM follower body axial displacement control of oil, the control of fuel injection advance unit control injection time |

| M N | BOSCH (Germany company) ECD – COVEC | Rotating magnet control sliding sleeve position, solenoid valve control injection time |

1.1.2 Time Type Electronic Control Fuel Injection System

Table of contents

- Cover

- Table of Contents

- Preface

- Introduction

- 1 Introduction

- 2 Common Rail System Simulation and Overall Design Technology

- 3 Electronically Controlled Injector Design Technologies

- 4 High‐Pressure Fuel Pump Design Technology

- 5 ECU Design Technique

- 6 Research on Matching Technology

- 7 Development of the Dual Pressure Common Rail System

- Index

- End User License Agreement