- English

- ePUB (mobile friendly)

- Available on iOS & Android

About this book

The bestselling step-by-step framing guide—updated and expanded to meet 2018 codes and standards

Complete Book of Framing, Second Edition—Updated and Expanded is a comprehensive guide to rough carpentry and framing, written by an expert with over forty years of framing experience. This book guides the reader through step-by-step framing instructions for floors, walls, roofs, door and window openings, and stairs. Hundreds of full-color illustrations and photos enable novice and professional framers to understand and master framing techniques.

This Updated and Expanded Second Edition includes the framing techniques of the 2018 International Building Code (IBC), International Residential Code (IRC), and updated OSHA rules. It also includes new coverage of today's electric tools, wind and earthquake framing, medical and physiological factors of framing, and a revised safety chapter. Builders will find information on nailing patters, overall layout, engineered wood patterns, and green framing. In addition, the book offers readers tools and techniques for preparing for a job and managing a team. This Second Edition—Updated and Expanded:

- Includes hundreds of full-color illustrations depicting step-by-step framing techniques

- Offers guidance on today's electric tools and structural enhancements for natural disasters

- Features a revised chapter on safety to reflect the medical and physiological factors of framing

- Meets the framing techniques of the 2018 International Building Code (IBC), International Residential Code (IRC), and Occupational Safety and Health Administration (OSHA) standards

Complete Book of Framing: An Illustrated Guide for Residential Construction, Second Edition—Updated and Expanded is an excellent resource for framers, carpenters, and contractors of all experience levels. Framer-friendly tips throughout the book show how to complete framing tasks efficiently and effectively.

Frequently asked questions

- Essential is ideal for learners and professionals who enjoy exploring a wide range of subjects. Access the Essential Library with 800,000+ trusted titles and best-sellers across business, personal growth, and the humanities. Includes unlimited reading time and Standard Read Aloud voice.

- Complete: Perfect for advanced learners and researchers needing full, unrestricted access. Unlock 1.4M+ books across hundreds of subjects, including academic and specialized titles. The Complete Plan also includes advanced features like Premium Read Aloud and Research Assistant.

Please note we cannot support devices running on iOS 13 and Android 7 or earlier. Learn more about using the app.

Information

Contents

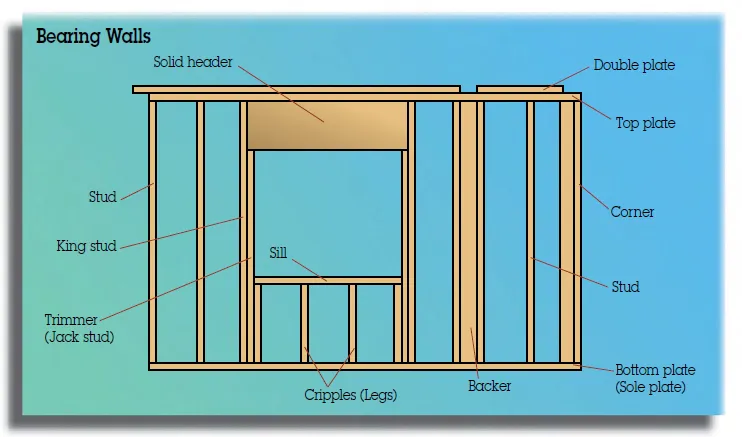

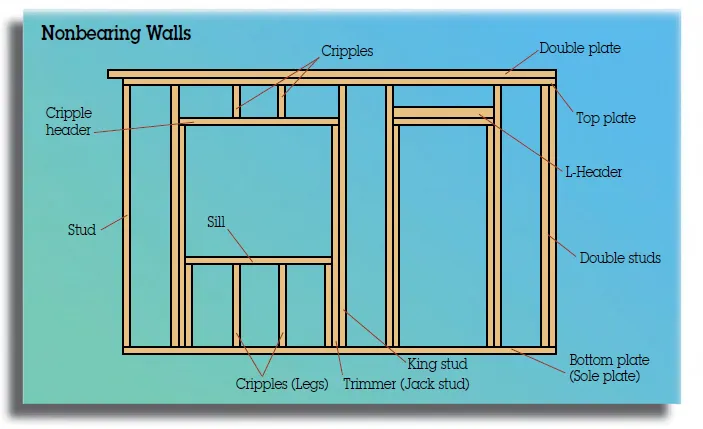

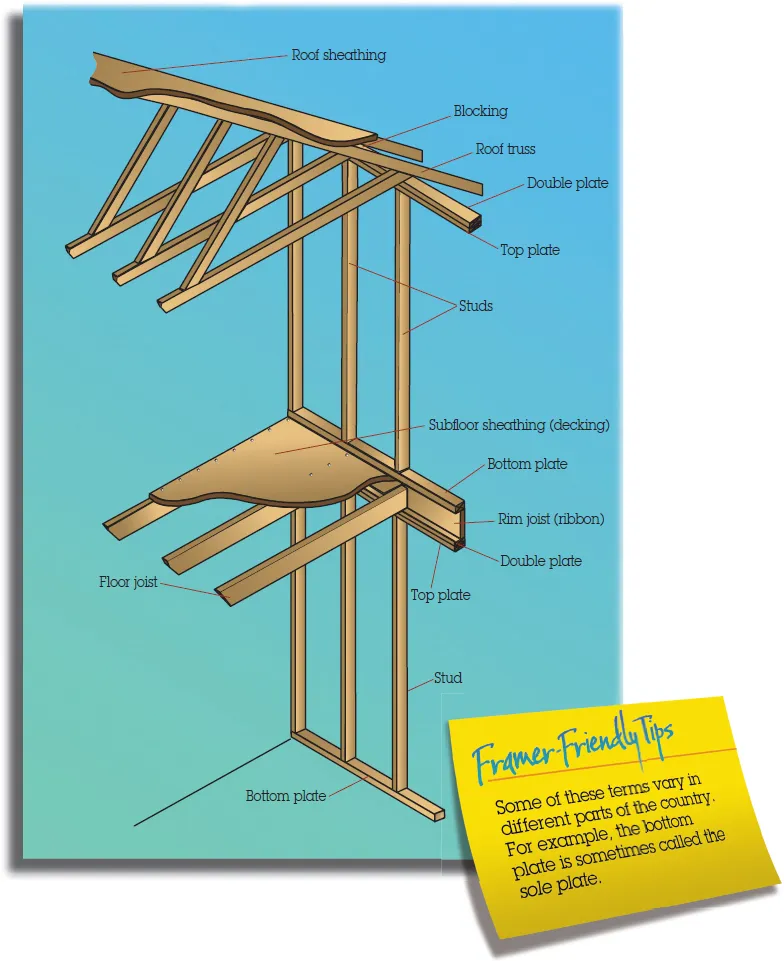

- Framing Terms

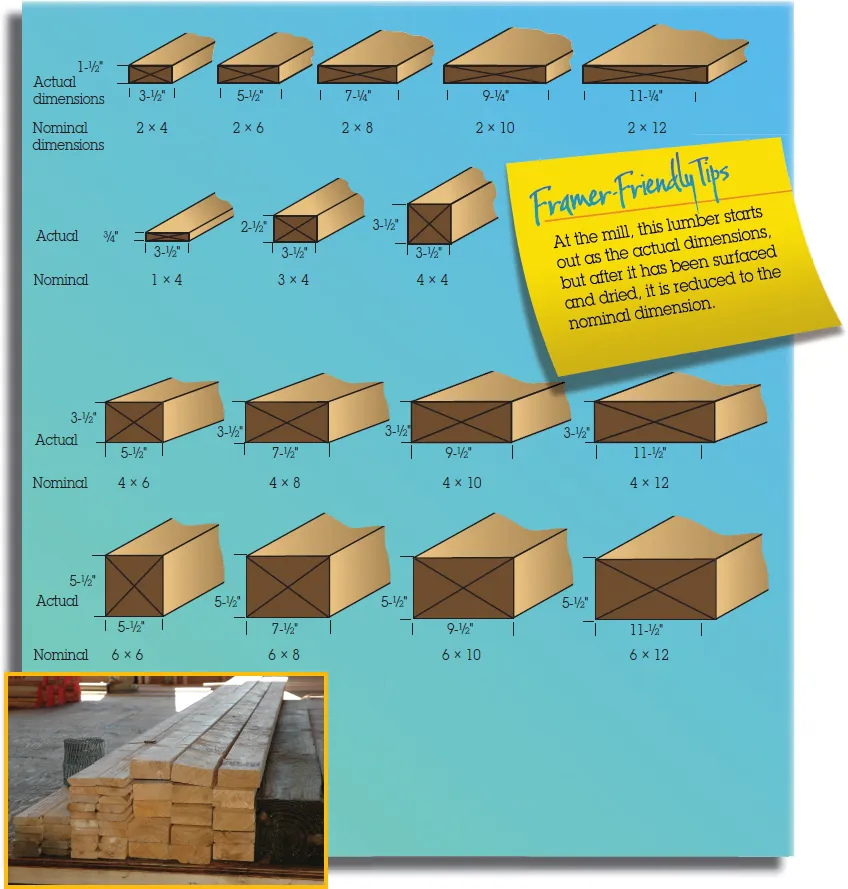

- Framing Lumber

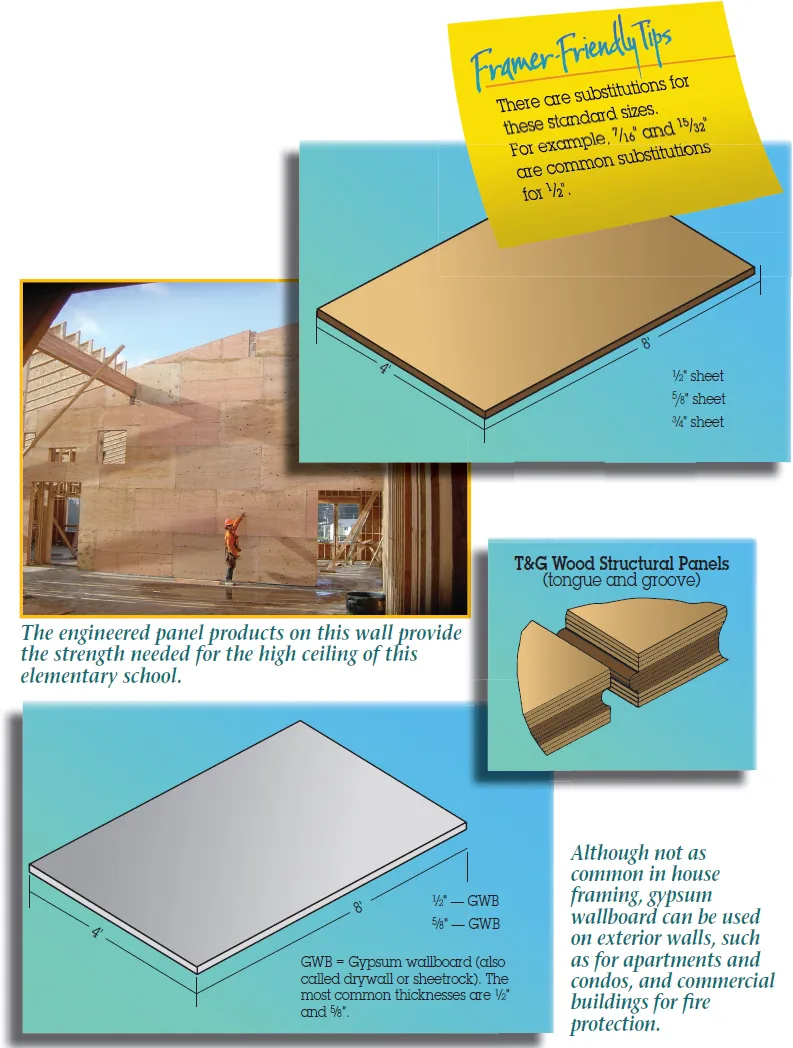

- Framing Sheathing

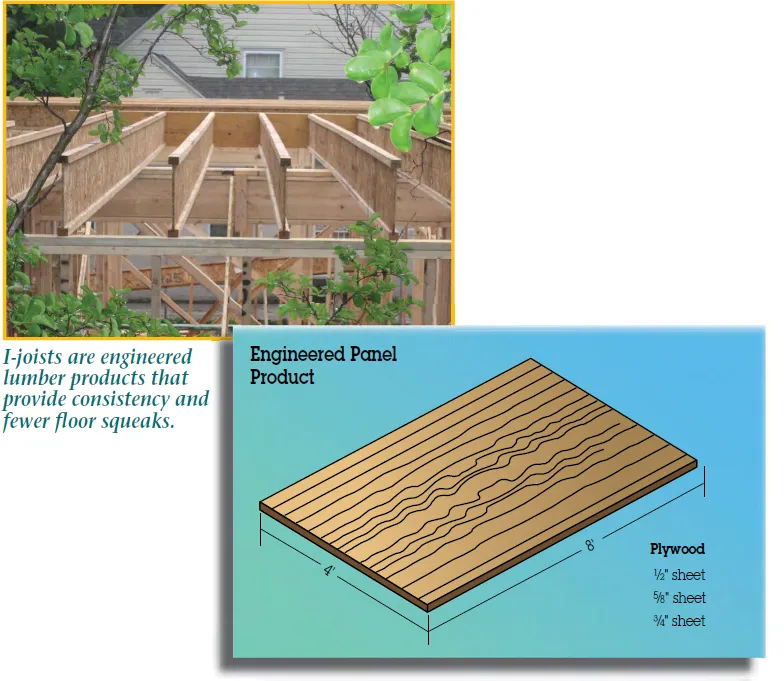

- Engineered Wood Products

- Lumber and Wood Structural Panel Grade Stamps

- Framing Nails

- Framing Tools

- Cordless Tools

- Framing Tool Truck

- Cutting Lumber

- Protecting Lumber from Decay

- Preservative Treated Wood

Framing Terms

Framing Lumber

Framing Sheathing

Engineered Panel Products

Engineered Wood Products

Table of contents

- Cover

- Title Page

- Copyright

- About the Author

- Acknowledgments

- Introduction

- Chapter One Introduction to Framing

- Chapter Two Nailing Patterns

- Chapter Three Floor Framing

- Chapter Four Wall Framing

- Chapter Five Roof Framing

- Chapter Six Doors, Windows, and Stairs

- Chapter Seven Layout

- Chapter Eight Engineered Wood products

- Chapter Nine Wind and Earthquake Framing

- Chapter Ten Building Code Requirements

- Chapter Eleven Green Framing

- Chapter Twelve Preparing for a Job

- Chapter Thirteen Managing the Framing Start

- Chapter Fourteen Managing a Framing Team

- Chapter Fifteen Safety

- Chapter Sixteen Healthy Framing

- Glossary

- WILEY END USER LICENSE AGREEMENT