- English

- ePUB (mobile friendly)

- Available on iOS & Android

Piping and Instrumentation Diagram Development

About this book

An essential guide for developing and interpreting piping and instrumentation drawings

Piping and Instrumentation Diagram Development is an important resource that offers the fundamental information needed for designers of process plants as well as a guide for other interested professionals. The author offers a proven, systemic approach to present the concepts of P&ID development which previously were deemed to be graspable only during practicing and not through training.

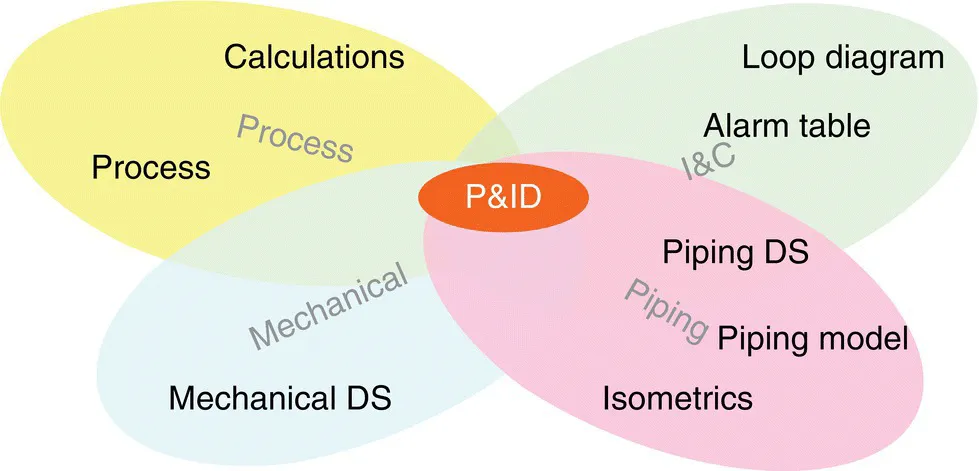

This comprehensive text offers the information needed in order to create P&ID for a variety of chemical industries such as: oil and gas industries; water and wastewater treatment industries; and food industries. The author outlines the basic development rules of piping and instrumentation diagram (P&ID) and describes in detail the three main components of a process plant: equipment and other process items, control system, and utility system. Each step of the way, the text explores the skills needed to excel at P&ID, includes a wealth of illustrative examples, and describes the most effective practices.

This vital resource:

- Offers a comprehensive resource that outlines a step-by-step guide for developing piping and instrumentation diagrams

- Includes helpful learning objectives and problem sets that are based on real-life examples

- Provides a wide range of original engineering flow drawing (P&ID) samples

- Includes PDF's that contain notes explaining the reason for each piece on a P&ID and additional samples to help the reader create their own P&IDs

Written for chemical engineers, mechanical engineers and other technical practitioners, Piping and Instrumentation Diagram Development reveals the fundamental steps needed for creating accurate blueprints that are the key elements for the design, operation, and maintenance of process industries.

Frequently asked questions

- Essential is ideal for learners and professionals who enjoy exploring a wide range of subjects. Access the Essential Library with 800,000+ trusted titles and best-sellers across business, personal growth, and the humanities. Includes unlimited reading time and Standard Read Aloud voice.

- Complete: Perfect for advanced learners and researchers needing full, unrestricted access. Unlock 1.4M+ books across hundreds of subjects, including academic and specialized titles. The Complete Plan also includes advanced features like Premium Read Aloud and Research Assistant.

Please note we cannot support devices running on iOS 13 and Android 7 or earlier. Learn more about using the app.

Information

Part I

Fundamentals of P&ID Development

1

What Is P&ID

1.1 Why Is P&ID Important?

Table of contents

- Cover

- Table of Contents

- Preface

- Acknowledgement

- About the Companion Website

- Part I: Fundamentals of P&ID Development

- Part II: Pipes and Equipment

- Part III: Instrumentation and Control System

- Part IV: Utilities

- Part V: Additional Information and General Procedure

- Index

- End User License Agreement