Process Architecture in Biomanufacturing Facility Design

- English

- ePUB (mobile friendly)

- Available on iOS & Android

Process Architecture in Biomanufacturing Facility Design

About this book

Essential information for architects, designers, engineers, equipment suppliers, and other professionals who are working in or entering the biopharmaceutical manufacturing field

Biomanufacturing facilities that are designed and built today are radically different than in the past. The vital information and knowledge needed to design and construct these increasingly sophisticated biopharmaceutical manufacturing facilities is difficult to find in published literature—and it's rarely taught in architecture or design schools. This is the first book for architects and designers that fills this void. Process Architecture in Biomanufacturing Facility Design provides information on design principles of biopharmaceutical manufacturing facilities that support emerging innovative processes and technologies, use state-of-the-art equipment, are energy efficient and sustainable, and meet regulatory requirements.

Relying on their many years of hands-on design and operations experience, the authors emphasize concepts and practical approaches toward design, construction, and operation of biomanufacturing facilities, including product-process-facility relationships, closed systems and single use equipment, aseptic manufacturing considerations, design of biocontainment facility and process based laboratory, and sustainability considerations, as well as an outlook on the facility of the future.

- Provides guidelines for meeting licensing and regulatory requirements for biomanufacturing facilities in the U.S.A and WHO—especially in emerging global markets in India, China, Latin America, and the Asia/Pacific regions

- Focuses on innovative design and equipment, to speed construction and time to market, increase energy efficiency, and reduce footprint, construction and operational costs, as well as the financial risks associated with construction of a new facility prior to the approval of the manufactured products by regulatory agencies

- Includes many diagrams that clarify the design approach

Process Architecture in Biomanufacturing Facility Design is an ideal text for professionals involved in the design of facilities for manufacturing of biopharmaceuticals and vaccines, biotechnology, and life-science industry, including architects and designers of industrial facilities, construction, equipment vendors, and mechanical engineers. It is also recommended for university instructors, advanced undergraduates, and graduate students in architecture, industrial engineering, mechanical engineering, industrial design, and industrial interior design.

Tools to learn more effectively

Saving Books

Keyword Search

Annotating Text

Listen to it instead

Information

Chapter 1

Introduction to Biomanufacturing

1.1 Introduction

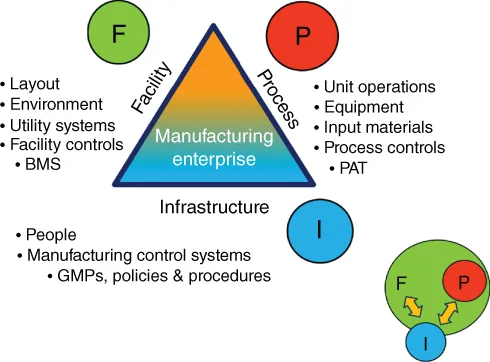

- Identify and describe a biopharmaceutical manufacturing enterprise's three basic elements (process, facility, and infrastructure);

- Briefly describe the constituents used in biopharmaceutical manufacturing processes to appreciate the complexity and fundamental issues of operating the process's unit operations (UOs) within the facility;

- Identify the basic process UOs typically used in biopharmaceutical manufacturing;

- Provide a framework for describing, evaluating, and controlling the facility and process UOs, and;

- Provide an understanding of how the overall manufacturing enterprise is operated and controlled.

1.2 The Basic Constituents of Biopharmaceuticals

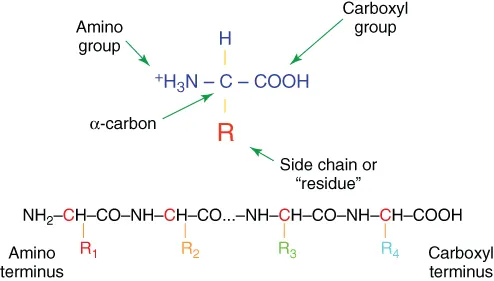

1.2.1 Proteins

- Primary: the linear amino acid sequence of the polypeptide;

- Secondary: the localized folding of the primary structure into substructures sometimes called helices, strands, and sheets;

- Tertiary: the combining of the secondary spiral and flat elements to form larger three-dimensional structures;

- Quaternary: combining of tertiary structures to form a much larger complex three-dimensional structures.

Table of contents

- Cover

- Title Page

- Copyright

- Table of Contents

- Dedication

- Contributors

- Foreword

- Preface: Why a Book on Process Architecture?

- Chapter 1: Introduction to Biomanufacturing

- Chapter 2: Product–Process–Facility Relationship

- Chapter 3: Regulatory Considerations of Biomanufacturing Facilities

- Chapter 4: Biopharmaceutical Facility Design and Validation

- Chapter 5: Closed Systems in Bioprocessing

- Chapter 6: Aseptic Manufacturing Considerations for Biomanufacturing Facility Design

- Chapter 7: Facility Control of Microorganisms: Containment and Contamination

- Chapter 8: Process-Based Laboratory Design

- Chapter 9: Case Study: Pharmaceutical Pilot Plant Design and Operation

- Chapter 10: Addressing Sustainability in Biomanufacturing Facility Design

- Chapter 11: Technology's Impact on the Biomanufacturing Facility of the Future

- Glossary

- Index

- End User License Agreement

Frequently asked questions

- Essential is ideal for learners and professionals who enjoy exploring a wide range of subjects. Access the Essential Library with 800,000+ trusted titles and best-sellers across business, personal growth, and the humanities. Includes unlimited reading time and Standard Read Aloud voice.

- Complete: Perfect for advanced learners and researchers needing full, unrestricted access. Unlock 1.4M+ books across hundreds of subjects, including academic and specialized titles. The Complete Plan also includes advanced features like Premium Read Aloud and Research Assistant.

Please note we cannot support devices running on iOS 13 and Android 7 or earlier. Learn more about using the app