- English

- ePUB (mobile friendly)

- Available on iOS & Android

Mechanics of Aeronautical Composite Materials

About this book

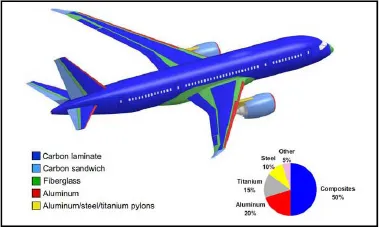

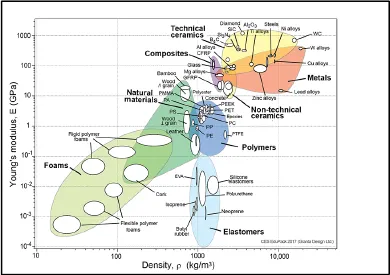

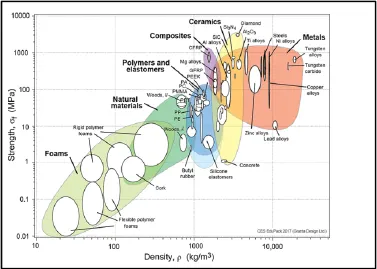

This book presents the principles of composite laminate sizing widely used for composite structures. The focus is on aeronautics in particular, including the concepts of limit loads and ultimate loads.

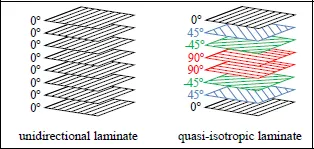

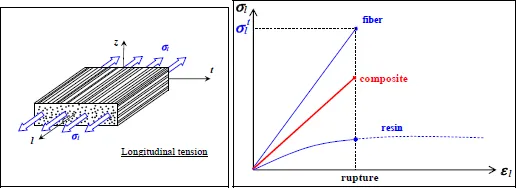

After a brief overview of the main composite materials used in aeronautics, the basic theory of laminated plates and the associated rupture criteria are given. The author presents two fundamental cases of the sizing of aeronautical composite structures: the calculation of the holed structures and their subsequent multi-bolt joints, and the calculation of the buckling.

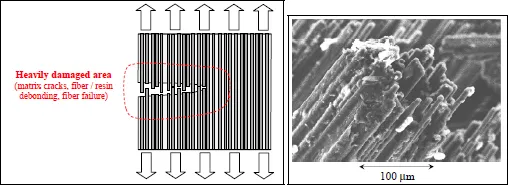

The concept of damage tolerance is also explored, with a focus on its application for tolerance to impact damage. These notions are fundamental for understanding the specificities of the sizing of aeronautical composite structures.

The book also contains corrected exercises for the reader to test their understanding of the different topics covered.

Frequently asked questions

- Essential is ideal for learners and professionals who enjoy exploring a wide range of subjects. Access the Essential Library with 800,000+ trusted titles and best-sellers across business, personal growth, and the humanities. Includes unlimited reading time and Standard Read Aloud voice.

- Complete: Perfect for advanced learners and researchers needing full, unrestricted access. Unlock 1.4M+ books across hundreds of subjects, including academic and specialized titles. The Complete Plan also includes advanced features like Premium Read Aloud and Research Assistant.

Please note we cannot support devices running on iOS 13 and Android 7 or earlier. Learn more about using the app.

Information

1

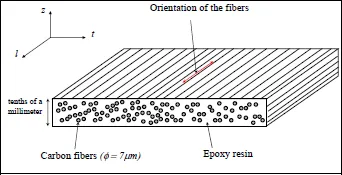

Presentation of an Aeronautical Unidirectional Composite

1.1. Introduction

1.2. Carbon/epoxy composite T300/914

1.3. Polymers

Table of contents

- Cover

- Table of Contents

- Title

- Copyright

- Foreword

- Preface

- Introduction

- 1 Presentation of an Aeronautical Unidirectional Composite

- 2 Characteristics of UD Ply

- 3 Characteristics of a UD Ply in a Given Direction

- 4 Fracture of a Laminated Composite

- 5 Fracture Criteria of a UD Ply

- 6 Membrane Behavior of a Laminated Composite Plate

- 7 Bending Behavior of a Laminated Composite Plate

- 8 The Fracture Criterion of a Laminate

- 9 Damage Tolerance

- 10 Interlaminar and Out-of-Plane Shear Stress

- 11 Holed and Bolted Plates

- 12 Buckling

- 13 Miscellaneous Rules for Stacking

- 14 Exercises

- 15 Solutions to the Exercises

- Bibliography

- Index

- End User License Agreement