eBook - ePub

A Practical Guide to Welding Solutions

Overcoming Technical and Material-Specific Issues

- English

- ePUB (mobile friendly)

- Available on iOS & Android

eBook - ePub

A Practical Guide to Welding Solutions

Overcoming Technical and Material-Specific Issues

About this book

As critically important as welding is to a wide spectrum of manufacturing, construction, and repair, it is not without its problems. Those dependent on welding know only too well how easy it is to find information on the host of available processes and on the essential metallurgy that can enable success, but how frustratingly difficult it can be to find guidance on solving problems that sooner or later arise with welding, welds, or weldments.

Here for the first time is the book those that practice and/or depend upon welding have needed and awaited. A Practical Guide to Welding Solutions addresses the numerous technical and material-specific issues that can interfere with success. Renowned industrial and academic welding expert and prolific author and speaker Robert W. Messler, Jr. guides readers to the solutions they seek with a well-organized search based on how a problem manifests itself (i.e., as distortion, defect, or appearance), where it appears (i.e., in the fusion zone heat-affected zone, or base metal), or it certain materials or situations.

Here for the first time is the book those that practice and/or depend upon welding have needed and awaited. A Practical Guide to Welding Solutions addresses the numerous technical and material-specific issues that can interfere with success. Renowned industrial and academic welding expert and prolific author and speaker Robert W. Messler, Jr. guides readers to the solutions they seek with a well-organized search based on how a problem manifests itself (i.e., as distortion, defect, or appearance), where it appears (i.e., in the fusion zone heat-affected zone, or base metal), or it certain materials or situations.

Tools to learn more effectively

Saving Books

Keyword Search

Annotating Text

Listen to it instead

Information

Edition

1Subtopic

Industrial & Technical Chemistry 1

Introduction

Welding as a process for joining materials, in general, and metals and alloys, in particular, is a double‐edged sword.1 On the one hand, welding offers one of the best methods for obtaining joints with strength comparable to (or even superior to) the physical elements being joined, with a lesser weight penalty than mechanical fastening (e.g. bolting or riveting) and a greater environmental durability than adhesive bonding (whether using organic adhesives, such as epoxies, or inorganic adhesives, such as cement). It also offers one of the assured ways of achieving leak tightness against fluids (i.e. gases and liquids), can be performed indoors or outdoors, manually or automatically (using mechanization or robots) using a wide variety of process embodiments, and, for better or worse, produces joints that are permanent.2 On the other hand, the use of welding always demands thoughtful structures and joint designs, proper equipment and consumables (e.g. shielding gases or fluxes and fillers), skilled operators, appropriate quality assurance for joint performance demands, and, most importantly, an understanding of what it takes to produce a sound weld. The latter requirement typically leads to most problems encountered with welding.

Problems with welding normally relate to unacceptable welds, i.e. welds that fail to pass nondestructive evaluation immediately following their production or welds that fail to provide intended functions in service. Some examples of the former include welded assemblies that fail to meet the geometric and dimensional criteria (i.e. do not provide needed fit and/or function), welds that contain surface or internal flaws or defects that fail to meet the required quality specifications (e.g. freedom from cracks and freedom from porosity), or welds that degraded the base material components (e.g. because of cracking, severe oxidation, hardness loss, or, contrarily, embrittlement). Also not to be ignored are welds that do not look good, as, in welding, internal “beauty” (i.e. quality) is often related to external “beauty” (i.e. appearance) the reason being a lack of care in welding, in particular, suggest a lack of care in manufacturing, in general, and, ultimately, a lack of care in design, marketing, senior management, etc. Very typically, the quality of an organization, starts at the top, with leadership by example meaning more than rules and regulations.

Figure 1.3a,b shows a couple of examples of extremely well‐executed welds made in stainless steel and an Al alloy using the gas tungsten arc process with a filler wire, whereas Figure 1.3c shows a very badly executed repair weld on a steel automobile part, and Figure 1.3d shows a badly factory‐made gas–metal arc repair weld on an Al alloy boat.

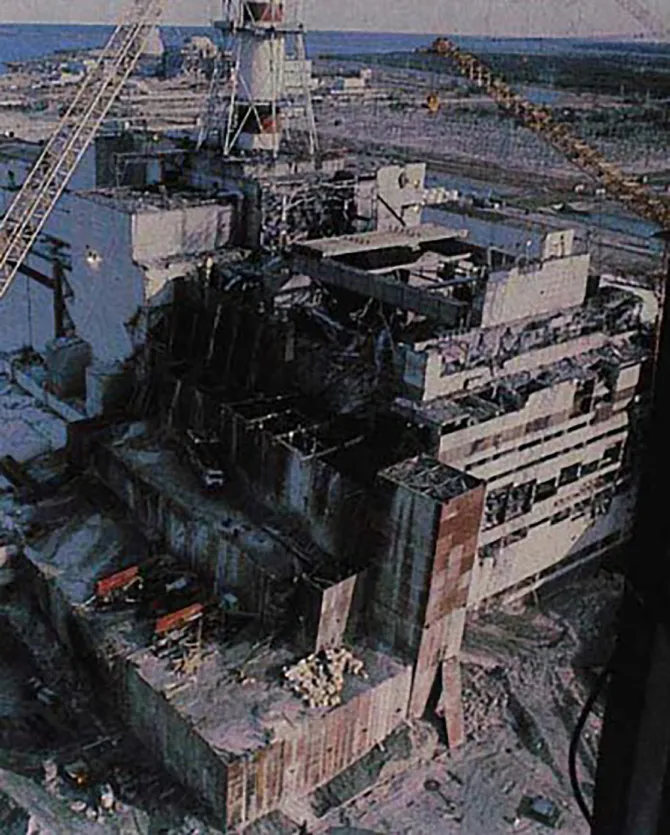

Figure 1.1 Remains of the #4 light water graphite‐moderated reactor unit at the Chernobyl Nuclear Power Plant near Pripyat in Ukraine shortly after it catastrophically failed on 26 April 1986, because of a series of errors by Soviet operators during safety check tests.

Source: Photograph by an unknown source posted by Garvey STS on en.wikibooks.org. Freely used under Creative Commons ShareAlike CC BY‐SA 4.0.

Figure 1.2 After several iterations to safely contain the highly radioactive remnants of the #4 reactor unit at the Chernobyl Nuclear Power Plant, the current New Safe Confinement or NSC was in position as of October 2017. Entombment was necessary because much of the steel structure used in the reactor containment vessel could not be disassembled as it was welded to be permanent and because it is highly radioactive. Besides safe containment of radiation, the €1.5B structure prevents damage by weather and runoff of lingering radioactive contamination.

Source: Wikipedia.com “Chernobyl new safe confinement”. Freely used under CC BY‐SA 4.0; posted by Tim Porter on 13 October 2017.

Figure 1.3 Two examples of superbly made fusion arc welds using manual gas tungsten arc (TIG) welding in (a) steel fittings and (b) Al alloy bicycle frames. In addition, two badly made welds: using a gas–metal arc to repair (c) a steel automobile part and (d) an Al alloy boat structure at a factory repair shop, with neither source being identified – fortunately for them – as images are in the public domain!

Source: The former by Scott Raabe at his Clean Cut Metal Works, Houston, TX, USA and used with his kind permission; and the latter on the website www.cycling.zanconato.com by Mike Zanconato at Zanconato Custom Cycles, Sutton, MA, USA and used with his kind permission.

To date, books that deal with the welding of metals and alloys, at least, have been found to deal with one or the other of (i) the processes employed to make welds or (ii) the metallurgy that underlies welding (i.e. welding metallurgy).3 The former seldom, if ever, mention problems with welding or welds, as welding, not welds, is their purpose. The latter typically spend the first 80–90% of the book presenting the underlying physical metallurgy that allow welds to be made in metals and alloys in the first place and that can produce sound structure in the weld (i.e. fusion zone and surrounding heat‐affected zone using fusion‐welding processes), if everything is done properly. The remaining 10–20% on what can go wrong, how to detect such short‐comings, and, finally, how to resolve any short‐coming(s). It is almost as if the author is telling a story and carefully avoiding the outcome, as in a mystery. Not surprisingly, producing high‐quality welds through welding is a mystery for many users.

This book will approach the problems with welding and the welds produced in a reverse order: starting with the problem(s) and working backward to the

cause(s) and resolution(s).4 As such, not to underestimate the ultimate importance of understanding the process (i.e. physics and chemistry) that is used to make a weld and, even more importantly, the physical metallurgy that underlies and enables the production of welds of sound quality and properties, but to simply deal with the nature of real‐world engineering in which pragmatism often prevails over detailed understanding of principles, the reason for the rising of various problems encountered will be covered briefly. Details will be left to the reader to seek information on welding metallurgy from other references. The rationale behind the approach of this book is as follows: engineers seek answers to problems and often achieve their goal(s) without having to delve into every detail. Every young engineer soon learns upon entering practice from college: the solution to a problem often only needs to be good enough, not perfect. A minimalist approach to engineering is often just as good as the minimalist approach used by a jockey to get a thoroughbred to win a race. Encourage the horse by clicks and chortles, tugs on the mane, and the light snap of a riding crop to increase the length of its stride at full gallop, without needing to know and understand all the details of equine physiology, like a veterinarian. After all, few veterinarians could ever ride a horse to victory in any race, no less in the Kentucky Derby!

This approach will work because those electing to use welding to create a structural assembly employ a backward problem‐solving technique anyway. Knowing the end goal of a challenge (e.g. to get a man onto the Moon and back to the Earth safely), they work backward from the desired goal to identify the steps, methods, and procedures needed at each step to incrementally reach that goal from some given starting point. Regrettably, this enlightenment only dawns on young engineers once they leave engineering school, where most of what they are taught is the step‐by‐step process for reaching a goal by starting from first principles and seeing where the steps lead.

The reason a backward problem‐solving approach often works, and often suffices, is that the first step will be to recognize the shortcoming (e.g. a severely distorted structure following cooling after welding; cracks in the fusion zone of a weld made i...

Table of contents

- Cover

- Table of Contents

- Preface

- 1 Introduction

- 2 Categorization of Welding and Weld Problems

- Part I Manifestation of Problems with Welds and Weldments

- Part II Location of Problems in Welds

- Part III Material-Specific Weld-Related Problems

- Closing Thoughts

- Index

- End User License Agreement

Frequently asked questions

Yes, you can cancel anytime from the Subscription tab in your account settings on the Perlego website. Your subscription will stay active until the end of your current billing period. Learn how to cancel your subscription

No, books cannot be downloaded as external files, such as PDFs, for use outside of Perlego. However, you can download books within the Perlego app for offline reading on mobile or tablet. Learn how to download books offline

Perlego offers two plans: Essential and Complete

- Essential is ideal for learners and professionals who enjoy exploring a wide range of subjects. Access the Essential Library with 800,000+ trusted titles and best-sellers across business, personal growth, and the humanities. Includes unlimited reading time and Standard Read Aloud voice.

- Complete: Perfect for advanced learners and researchers needing full, unrestricted access. Unlock 1.4M+ books across hundreds of subjects, including academic and specialized titles. The Complete Plan also includes advanced features like Premium Read Aloud and Research Assistant.

We are an online textbook subscription service, where you can get access to an entire online library for less than the price of a single book per month. With over 1 million books across 990+ topics, we’ve got you covered! Learn about our mission

Look out for the read-aloud symbol on your next book to see if you can listen to it. The read-aloud tool reads text aloud for you, highlighting the text as it is being read. You can pause it, speed it up and slow it down. Learn more about Read Aloud

Yes! You can use the Perlego app on both iOS and Android devices to read anytime, anywhere — even offline. Perfect for commutes or when you’re on the go.

Please note we cannot support devices running on iOS 13 and Android 7 or earlier. Learn more about using the app

Please note we cannot support devices running on iOS 13 and Android 7 or earlier. Learn more about using the app

Yes, you can access A Practical Guide to Welding Solutions by Robert W. Messler, Jr. in PDF and/or ePUB format, as well as other popular books in Technology & Engineering & Industrial & Technical Chemistry. We have over one million books available in our catalogue for you to explore.