- English

- ePUB (mobile friendly)

- Available on iOS & Android

Multi-physics Modeling of Technological Systems

About this book

The development of mechatronic and multidomain technological systems requires the dynamic behavior to be simulated before detailed CAD geometry is available. This book presents the fundamental concepts of multiphysics modeling with lumped parameters. The approach adopted in this book, based on examples, is to start from the physical concepts, move on to the models and their numerical implementation, and finish with their analysis. With this practical problem-solving approach, the reader will gain a deep understanding of multiphysics modeling of mechatronic or technological systems – mixing mechanical power transmissions, electrical circuits, heat transfer devices and electromechanical or fluid power actuators. Most of the book's examples are made using Modelica platforms, but they can easily be implemented in other 0D/1D multidomain physical system simulation environments such as Amesim, Simulink/Simscape, VHDL-AMS and so on.

Tools to learn more effectively

Saving Books

Keyword Search

Annotating Text

Listen to it instead

Information

1

Role of Simulation in the Design Cycle of Complex Technological Systems

1.1. Approach to the design of complex systems

- – The multi-level design aspect of the prototype requirements, coupled with the necessity for multi-view (system, geometric, structural, behavioral, etc.) descriptions;

- – Multi-domain aspect (automation, mechanics, computing, electronics, etc.);

- – Multi-scale (geometric and temporal) refinement levels;

- – Finally, interactions between (multidisciplinary) teams.

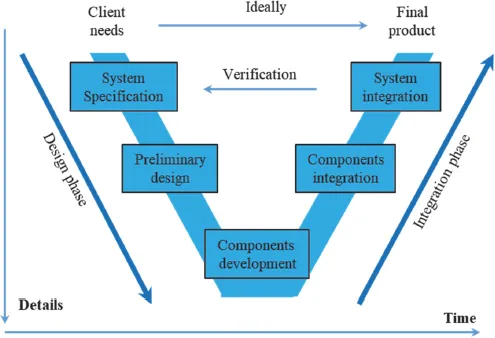

1.1.1. Engineering activities in the design cycle

- – “System specification” level. This phase justifies the creation of a system and defines what it should do to adequately satisfy the needs expressed by its potential users. This involves conducting a functional analysis of the need and implementing a Functional Specifications Document (FSD);

- – “Preliminary design” level. This phase enables the precise definition of what the system should be, the choice of various components and technical solutions, as well as the way in which they are interconnected. The system architect defines, at this level, one or several solution concepts. These concepts are evaluated against the functions and requirements defined in the previous phase, as well as against various technical, economic or other criteria. Only one concept is finally retained. The comparison of various potential solutions relies on the definition of their logical architecture (information chain) and structural architecture (power chain) and on the sizing of their parts. At the end of this phase, a file of specifications for the detailed design of various hardware and software components (parts) must be generated;

- – “Components development” or “geometric” level. This level involves the final choice of components. Professionals specializing in various fields (mechanics, electronics, heat transfer, etc.) size and optimize each part, to make sure that the specifications formulated in the previous stage are met. In-depth analysis of the components is also conducted under specific physical conditions (field of mechanical stresses, deformations, temperatures, fluxes, etc.). Digital prototypes are built and manufacturing plans are defined. Computer codes are implemented.

1.1.2. Modeling and simulation roles in the design cycle

Table of contents

- Cover

- Table of Contents

- Foreword

- 1 Role of Simulation in the Design Cycle of Complex Technological Systems

- 2 Fundamental Concepts of Lumped Parameter-Based Multi-Physics Modeling

- 3 Setting Up a Lumped Parameter Model

- 4 Numerical Simulation of Multi-Physics Systems

- 5 Dynamic Performance Analysis Tools

- 6 Mechanical and Electromechanical Power Transmissions

- 7 Power Transmission by Low-Compressibility Fluids

- 8 Heat Power Transmission

- 9. Thermal Power Conversion

- References

- Index

- End User License Agreement

Frequently asked questions

- Essential is ideal for learners and professionals who enjoy exploring a wide range of subjects. Access the Essential Library with 800,000+ trusted titles and best-sellers across business, personal growth, and the humanities. Includes unlimited reading time and Standard Read Aloud voice.

- Complete: Perfect for advanced learners and researchers needing full, unrestricted access. Unlock 1.4M+ books across hundreds of subjects, including academic and specialized titles. The Complete Plan also includes advanced features like Premium Read Aloud and Research Assistant.

Please note we cannot support devices running on iOS 13 and Android 7 or earlier. Learn more about using the app