- English

- ePUB (mobile friendly)

- Available on iOS & Android

eBook - ePub

About this book

In this expert handbook both the topics and contributors are selected so as to provide an authoritative view of possible applications for this new technology. The result is an up-to-date survey of current challenges and opportunities in the design and operation of bioreactors for high-value products in the biomedical and chemical industries.

Combining theory and practice, the authors explain such leading-edge technologies as single-use bioreactors, bioreactor simulators, and soft sensor monitoring, and discuss novel applications, such as stem cell production, process development, and multi-product reactors, using case studies from academia as well as from industry. A final section addresses the latest trends, including culture media design and systems biotechnology, which are expected to have an increasing impact on bioreactor design.

With its focus on cutting-edge technologies and discussions of future developments, this handbook will remain an invaluable reference for many years to come.

Combining theory and practice, the authors explain such leading-edge technologies as single-use bioreactors, bioreactor simulators, and soft sensor monitoring, and discuss novel applications, such as stem cell production, process development, and multi-product reactors, using case studies from academia as well as from industry. A final section addresses the latest trends, including culture media design and systems biotechnology, which are expected to have an increasing impact on bioreactor design.

With its focus on cutting-edge technologies and discussions of future developments, this handbook will remain an invaluable reference for many years to come.

Frequently asked questions

Yes, you can cancel anytime from the Subscription tab in your account settings on the Perlego website. Your subscription will stay active until the end of your current billing period. Learn how to cancel your subscription.

No, books cannot be downloaded as external files, such as PDFs, for use outside of Perlego. However, you can download books within the Perlego app for offline reading on mobile or tablet. Learn more here.

Perlego offers two plans: Essential and Complete

- Essential is ideal for learners and professionals who enjoy exploring a wide range of subjects. Access the Essential Library with 800,000+ trusted titles and best-sellers across business, personal growth, and the humanities. Includes unlimited reading time and Standard Read Aloud voice.

- Complete: Perfect for advanced learners and researchers needing full, unrestricted access. Unlock 1.4M+ books across hundreds of subjects, including academic and specialized titles. The Complete Plan also includes advanced features like Premium Read Aloud and Research Assistant.

We are an online textbook subscription service, where you can get access to an entire online library for less than the price of a single book per month. With over 1 million books across 1000+ topics, we’ve got you covered! Learn more here.

Look out for the read-aloud symbol on your next book to see if you can listen to it. The read-aloud tool reads text aloud for you, highlighting the text as it is being read. You can pause it, speed it up and slow it down. Learn more here.

Yes! You can use the Perlego app on both iOS or Android devices to read anytime, anywhere — even offline. Perfect for commutes or when you’re on the go.

Please note we cannot support devices running on iOS 13 and Android 7 or earlier. Learn more about using the app.

Please note we cannot support devices running on iOS 13 and Android 7 or earlier. Learn more about using the app.

Yes, you can access Bioreactors by Carl-Fredrik Mandenius in PDF and/or ePUB format, as well as other popular books in Biological Sciences & Biotechnology. We have over one million books available in our catalogue for you to explore.

Information

Chapter 1

Challenges for Bioreactor Design and Operation

Carl-Fredrik Mandenius

1.1 Introduction

As per definition, the bioreactor is the designed space where biological reactions take place. Hence, the bioreactor is essentially an engineering achievement and its design a challenge for bioengineers.

The bioreactor should create a biosphere that as profoundly and adequately as possible provides the ideal environment for the biological reaction.

The path for reaching, attaining, and maintaining this is the main task for bioreactor engineers to find. That task decomposes into several endeavors necessary to accomplish. One is to design the physical entity of the bioreactor itself – by that, ensuring favorable physical conditions for transport of gases and liquids and solids over time. Another is to ensure that the physical entity of the bioreactor is favorably adapted to the biological system that performs the bioreactions. Yet another is to ensure that the dynamic biophysical and biochemical events taking place are operable in an industrial environment.

In some of these design perspectives, bioreactor design is addressed at a process development stage where the performance of operations is independent of scale or biological system inside the bioreactor. Others address specific biological systems and the particular requirements of these. Others take the viewpoint at the holistic level: how to integrate the bioreactor and its design into an entire bioprocess with the constraints that this creates. Others concern provision of methodologies for observing the bioreactor at R&D as well as at operation stages in order to monitor and control and to optimize its performance from a variety of needs and purposes. Others provide better methods for supporting plant engineers and technicians to manage to operate the bioreactor processes under unpredictable industrial conditions where unexpected events, faults, and mishaps must be interpreted in short time and acted upon.

Importantly, all these aspects on design and operation may, and even must, be amalgamated into coherent design methodologies that are conceivable and practically achievable. It is the ambition of this book to provide a collection of design options where engineering principles and design tools are presented that facilitate to develop and apply good solutions to emerging needs in bioreactor design.

1.2 Biotechnology Milestones with Implications on Bioreactor Design

The bioreactor is a historical apparatus known since ancient times. Old antique cultures were able to solve bioengineering design challenges for practical purposes such as wine and beer making from mere experience and observations. This paved the way for the evolvement of biotechnological processes, primarily for preparation and production of food products [1].

The notion that microscopic life is a huge industrial resource came gradually to man and with some resistance from the established scientific society itself. An array of fundamental scientific steps paved the way for the unfolding of industrial biotechnology. Growing understanding of the mechanisms of diseases and its interplay with cell biology supported the development.

In the early nineteenth century, scientists such as Lorenz Oken (1779–1851), Theodor Schwann (1810–1882), and others did stepwise begin to fathom the fundamental principles of the cell's behavior in the body and in culture [2]. Louis Pasteur (1822–1895) took these observations and conclusions further into a coherent description of the fermentation mechanisms [3]. Later, researchers such as Emile Roux (1853–1933) and Robert Koch (1843–1910) realized the implications to bacteriology and for spread of diseases. These consorted ascents in cell biology and medicine did synergistically create the necessary background for the exploitation of the industrial potential of cells. By that, also important prerequisites for a furthering of bioreactor design were set.

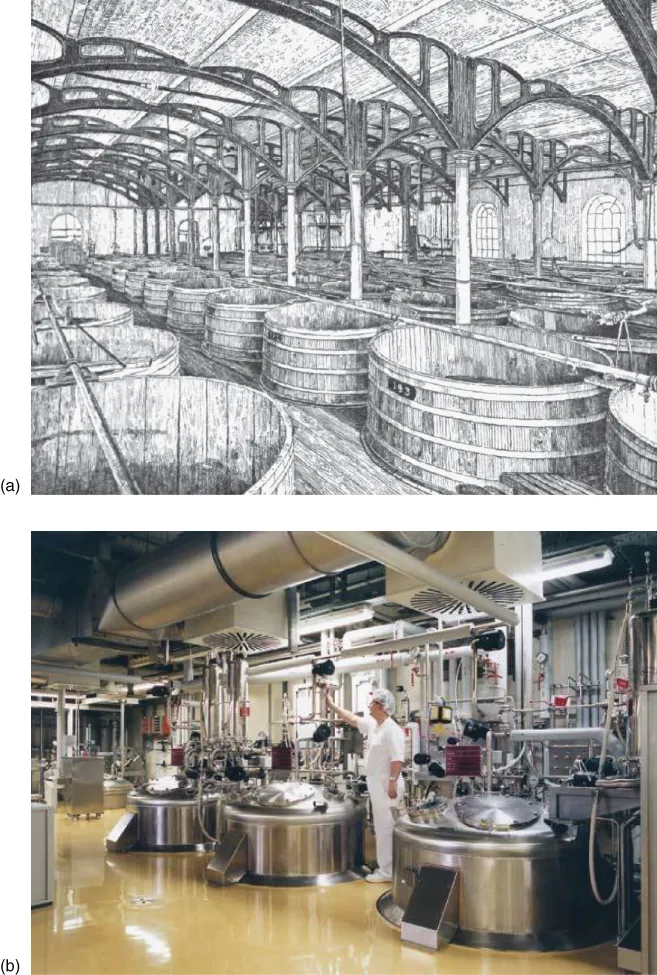

The microbiology research brought better insights into the up-till-then-hidden processes of the cell and, hence, to the development of bioengineering and to the widespread industrial biotechnology applications during the twentieth century. It is in this framework of bioindustrial activity and progress the bioreactors and their design have been shaped. Still, it is noteworthy that 100 years ago an industrial bioreactor facility did not look too different from today's industrial sites (Figure 1.1).

Figure 1.1 (a) An old fermentation plant from the late nineteenth century. (b) A modern fermentation plant one century later. The gap in time between the plants reveals that some of the design features have undergone changes, while others are unchanged: the bioreactors are cylindrical vessels, the containment of the broth and concern about contamination were in former days less, piping are essential, many vessels are using the available plant space, and few plant operators are close to the process.

In the early twentieth century, large-scale fermentation processes were set up with impact onto the war-time industry of that period. Glycerol production for use in the manufacture of explosives, using yeast for conversion from glucose, was established. Another contemporary example is the large-scale production of butanol and acetone by butyric acid bacteria, as developed by Chaim Weizmann, used first for explosives and then for rubber manufacture in the emerging car industry [4]. However, these bio...

Table of contents

- Cover

- Title Page

- Copyright

- Table of Contents

- Preface

- List of Contributors

- Chapter 1: Challenges for Bioreactor Design and Operation

- Chapter 2: Design and Operation of Microbioreactor Systems for Screening and Process Development

- Chapter 3: Bioreactors on a Chip

- Chapter 4: Scalable Manufacture for Cell Therapy Needs

- Chapter 5: Artificial Liver Bioreactor Design

- Chapter 6: Bioreactors for Expansion of Pluripotent Stem Cells and Their Differentiation to Cardiac Cells

- Chapter 7: Culturing Entrapped Stem Cells in Continuous Bioreactors

- Chapter 8: Coping with Physiological Stress During Recombinant Protein Production by Bioreactor Design and Operation

- Chapter 9: Design, Applications, and Development of Single-Use Bioreactors

- Chapter 10: Computational Fluid Dynamics for Bioreactor Design

- Chapter 11: Scale-Up and Scale-Down Methodologies for Bioreactors

- Chapter 12: Integration of Bioreactors with Downstream Steps

- Chapter 13: Multivariate Modeling for Bioreactor Monitoring and Control

- Chapter 14: Soft Sensor Design for Bioreactor Monitoring and Control

- Chapter 15: Design-of-Experiments for Development and Optimization of Bioreactor Media

- Chapter 16: Operator Training Simulators for Bioreactors

- Index

- End User License Agreement