- English

- ePUB (mobile friendly)

- Available on iOS & Android

eBook - ePub

Freeze-Drying

About this book

This completely updated and enlarged third edition of the classic text adopts a practical approach to describe the fundamentals of freeze-drying, backed by many explanatory examples.

Following an introduction to the fundamentals, the book goes on to discuss process and plant automation as well as methods to transfer pilot plant qualifications and process data to production. An entire section is devoted to a large range of different pharmaceutical, biological, and medical products. New to this edition are chapters on antibodies, freeze-dry microscopy, TEMPRIS, microwave freeze-drying, spray freeze-drying, and PAT.

Their many years of experience in freeze-drying enable the authors to supply valuable criteria for the selection of laboratory, pilot and production plants, discussing the advantages, drawbacks and limitations of different plant designs. Alongside guidelines for the evaluation and qualification of plants and processes, the author also includes a troubleshooting section.

Following an introduction to the fundamentals, the book goes on to discuss process and plant automation as well as methods to transfer pilot plant qualifications and process data to production. An entire section is devoted to a large range of different pharmaceutical, biological, and medical products. New to this edition are chapters on antibodies, freeze-dry microscopy, TEMPRIS, microwave freeze-drying, spray freeze-drying, and PAT.

Their many years of experience in freeze-drying enable the authors to supply valuable criteria for the selection of laboratory, pilot and production plants, discussing the advantages, drawbacks and limitations of different plant designs. Alongside guidelines for the evaluation and qualification of plants and processes, the author also includes a troubleshooting section.

Tools to learn more effectively

Saving Books

Keyword Search

Annotating Text

Listen to it instead

Information

1

Foundations and Process Engineering

Freeze-drying or lyophilization is a drying process in which the solvent and/or the suspension medium is crystallized at low temperatures and thereafter sublimed from the solid state directly into the vapor phase.

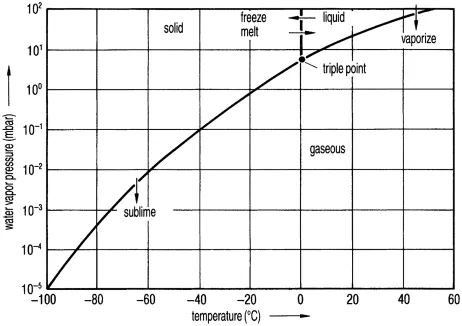

Freeze-drying is mostly done with water as solvent. Figure 1.1 shows the phase diagram of water and the area in which this transfer from solid to vapor is possible.

Figure 1.1 Phase diagram of water.

Table 1.1 shows the relation of temperature (°C), mTorr, and mbar.

Table 1.1 Vapor pressure of water.

| Temperature (°C) | mTorr | mbar | Temperature (°C) | mTorr | mbar |

| 0 | 4579 | 6.108 | −40 | 96.6 | 0.1238 |

| −4 | 3280 | 4.372 | −44 | 60.9 | 0.0809 |

| −8 | 2326 | 3.097 | −48 | 37.8 | 0.0502 |

| −12 | 1832 | 2.172 | −52 | 23.0 | 0.0300 |

| −16 | 1132 | 1.506 | −56 | 13.8 | 0.0183 |

| −20 | 930 | 1.032 | −60 | 8.0 | 0.0107 |

| −24 | 526 | 0.6985 | −64 | 4.6 | 0.0061 |

| −28 | 351 | 0.4669 | −68 | 2.8 | 0.0034 |

| −32 | 231 | 0.3079 | −72 | 1.4 | 0.0018 |

| −36 | 150 | 0.2020 |

This step is relatively straightforward for pure water. If the product contains two or more components in true solutions or suspensions, the situation can become so complicated that simplified model substances have to be used to make the process more understandable. Such complex systems occur ubiquitously in biological substances.

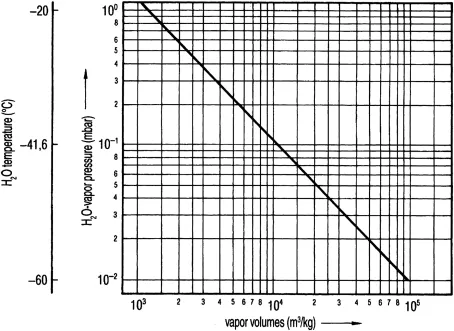

The drying transforms the ice or water in an amorphous phase into vapor. Owing to the low vapor pressure of the ice, the vapor volumes become large, as can be seen in Figure 1.2. During the second step of the drying, the water adsorbed on the solids is desorbed.

Figure 1.2 Specific volume of water vapor as a function of the water vapor pressure. The temperature of the vapor in this diagram is that of ice.

The goal of freeze-drying is to produce a substance with good shelf stability and which is unchanged after reconstitution with water, although this depends also very much on the last step of the process: the packing and conditions of storage.

The advantages of freeze-drying can be summarized as follows:

- The drying at low temperatures reduces degradation of heat-sensitive products.

- The liquid product can be accurately dosed.

- The moisture content of the final product can be controlled during the process.

- The dry product can have an appealing physical form.

- The dry product with a high specific surface area is rapidly reconstituted.

The disadvantages are as follows:

- The high investment, operating and maintenance costs.

- The complexity of the process and the equipment requires a team of skilled and permanently trained collaborators.

1.1 Freezing

To freeze a substance, it must be cooled to a temperature at which the water and the solids are fully crystallized or at which areas of crystallized ice and solids are enclosed in zones in which amorphous concentrated solids and water remain in a mechanically solid state (see Section 1.1.2). In the zone of freezing, the ice crystals first grow, thus concentrating the remaining solution, which can vary the pH value. In many substances an eutectic temperature can be determined, but in many others this value does not exist. The crystallization depends on several factors that influence each other: cooling rate, initial concentration, end temperature of cooling, and the time at this temperature. In several products, no crystallization takes place and the ...

Table of contents

- Cover

- Title Page

- Copyright

- Preface to Third Edition and Acknowledgment

- Preface to the Second Edition

- Chapter 1: Foundations and Process Engineering

- Chapter 2: Installation and Equipment Technique

- Chapter 3: Pharmaceutical, Biological, and Medical Products

- Chapter 4: Metal Oxides, Ceramic Powders

- Chapter 5: Trouble Shooting

- Chapter 6: Regulatory Issues

- Appendix: Abbreviations, Symbols, and Unit of Measure

- Index

- End User License Agreement

Frequently asked questions

Yes, you can cancel anytime from the Subscription tab in your account settings on the Perlego website. Your subscription will stay active until the end of your current billing period. Learn how to cancel your subscription

No, books cannot be downloaded as external files, such as PDFs, for use outside of Perlego. However, you can download books within the Perlego app for offline reading on mobile or tablet. Learn how to download books offline

Perlego offers two plans: Essential and Complete

- Essential is ideal for learners and professionals who enjoy exploring a wide range of subjects. Access the Essential Library with 800,000+ trusted titles and best-sellers across business, personal growth, and the humanities. Includes unlimited reading time and Standard Read Aloud voice.

- Complete: Perfect for advanced learners and researchers needing full, unrestricted access. Unlock 1.4M+ books across hundreds of subjects, including academic and specialized titles. The Complete Plan also includes advanced features like Premium Read Aloud and Research Assistant.

We are an online textbook subscription service, where you can get access to an entire online library for less than the price of a single book per month. With over 1 million books across 990+ topics, we’ve got you covered! Learn about our mission

Look out for the read-aloud symbol on your next book to see if you can listen to it. The read-aloud tool reads text aloud for you, highlighting the text as it is being read. You can pause it, speed it up and slow it down. Learn more about Read Aloud

Yes! You can use the Perlego app on both iOS and Android devices to read anytime, anywhere — even offline. Perfect for commutes or when you’re on the go.

Please note we cannot support devices running on iOS 13 and Android 7 or earlier. Learn more about using the app

Please note we cannot support devices running on iOS 13 and Android 7 or earlier. Learn more about using the app

Yes, you can access Freeze-Drying by Peter Haseley,Georg-Wilhelm Oetjen in PDF and/or ePUB format, as well as other popular books in Physical Sciences & Industrial & Technical Chemistry. We have over one million books available in our catalogue for you to explore.