- English

- ePUB (mobile friendly)

- Available on iOS & Android

eBook - ePub

About this book

An integral overview of the theory and design of printheads, authored by an expert with over 30 years' experience in the field of inkjet printing.

Clearly structured, the book presents the design of a printhead in a comprehensive and clear form, right from the start. To begin with, the working principle of piezo-driven drop-on-demand printheads in theory is discussed, building on the theory of mechanical vibrations and acoustics. Then the design of single-nozzle as well as multi-nozzle printheads is presented, including the importance of various parameters that need to be optimized, such as viscosity, surface tension and nozzle shape. Topics such as refilling the nozzle and the impact of the droplet on the surface are equally treated. The text concludes with a unique set of worked-out questions for training purposes as well as case studies and a look at what the future holds.

An essential reference for beginning as well as experienced researchers, from ink developers to mechanical engineers, both in industry and academia.

Clearly structured, the book presents the design of a printhead in a comprehensive and clear form, right from the start. To begin with, the working principle of piezo-driven drop-on-demand printheads in theory is discussed, building on the theory of mechanical vibrations and acoustics. Then the design of single-nozzle as well as multi-nozzle printheads is presented, including the importance of various parameters that need to be optimized, such as viscosity, surface tension and nozzle shape. Topics such as refilling the nozzle and the impact of the droplet on the surface are equally treated. The text concludes with a unique set of worked-out questions for training purposes as well as case studies and a look at what the future holds.

An essential reference for beginning as well as experienced researchers, from ink developers to mechanical engineers, both in industry and academia.

Frequently asked questions

Yes, you can cancel anytime from the Subscription tab in your account settings on the Perlego website. Your subscription will stay active until the end of your current billing period. Learn how to cancel your subscription.

No, books cannot be downloaded as external files, such as PDFs, for use outside of Perlego. However, you can download books within the Perlego app for offline reading on mobile or tablet. Learn more here.

Perlego offers two plans: Essential and Complete

- Essential is ideal for learners and professionals who enjoy exploring a wide range of subjects. Access the Essential Library with 800,000+ trusted titles and best-sellers across business, personal growth, and the humanities. Includes unlimited reading time and Standard Read Aloud voice.

- Complete: Perfect for advanced learners and researchers needing full, unrestricted access. Unlock 1.4M+ books across hundreds of subjects, including academic and specialized titles. The Complete Plan also includes advanced features like Premium Read Aloud and Research Assistant.

We are an online textbook subscription service, where you can get access to an entire online library for less than the price of a single book per month. With over 1 million books across 1000+ topics, we’ve got you covered! Learn more here.

Look out for the read-aloud symbol on your next book to see if you can listen to it. The read-aloud tool reads text aloud for you, highlighting the text as it is being read. You can pause it, speed it up and slow it down. Learn more here.

Yes! You can use the Perlego app on both iOS or Android devices to read anytime, anywhere — even offline. Perfect for commutes or when you’re on the go.

Please note we cannot support devices running on iOS 13 and Android 7 or earlier. Learn more about using the app.

Please note we cannot support devices running on iOS 13 and Android 7 or earlier. Learn more about using the app.

Yes, you can access Design of Piezo Inkjet Print Heads by J. Frits Dijksman in PDF and/or ePUB format, as well as other popular books in Technology & Engineering & Materials Science. We have over one million books available in our catalogue for you to explore.

Information

1

Introduction

Droplet‐on‐demand (DoD) inkjet print heads can be found in a range of different designs, from the single nozzle piezo‐driven micropipette (Microdrop (www.microdrop.com), MicroFab (www.microfab.com)) up to print heads with thousands of nozzles integrated (Xaar (www.xaar.com), Seiko‐Epson (http://global.epson.com/innovation/core_technology/micro_piezo.html), Fujifilm‐Dimatix (http://www.fujifilmusa.com/products/industrial_inkjet_printheads/), HP (www.hp.com), Konica‐Minolta (https://www.konicaminolta.com/inkjet/inkjethead/index.html), Memjet (www.memjet.com), Canon (www.canon.com, www.oce.com), Brother (www.brother.com)).

The sub‐assembly of the system of which the print head is part of, contains the print head, an ink reservoir of which the pressure is kept a level such that the print head does not leak when idling, an ink conveying supply line and electronics to drive the actuators of the different nozzles. An inkjet print head is an open fluidic system without any valves to control the flow direction. Surface tension and some under‐pressure keeps the fluid inside; the main flow direction is controlled by surface tension and inertia forces [1].

Focussing on the mechanism that generates droplets, all print heads are basically the same; behind each nozzle there is a small chamber, and each chamber is connected to the main ink supply, either directly or by a small duct called the throttle. In a piezoelectric‐driven print head, part of the wall of the chamber is covered with a piezoelectric platelet. In a bubble jet (thermal) print head, a part of the pump chamber is covered with a small resistor plate [2]. When the piezo platelet is activated in a pulse‐wise fashion, a pressure wave is generated that travels towards the nozzle, speeding up the fluid velocity in the nozzle [3]. The velocity is so high that ultimately a droplet or a series of droplets is formed. By applying an electrical pulse to the resistor plate, locally the fluid will be heated and turned into vapour. The sudden formation of the vapour bubble pushes the fluid through the nozzle and results into a droplet or a series of droplets. Viscous dissipation causes the fluid in the nozzle to come to a standstill after a few oscillations. After replenishing of the volume of the droplet(s) by surface tension and asymmetry effects in the nozzle caused by the meniscus motion and emptying of the nozzle due to droplet formation, the system is ready for the next pulse.

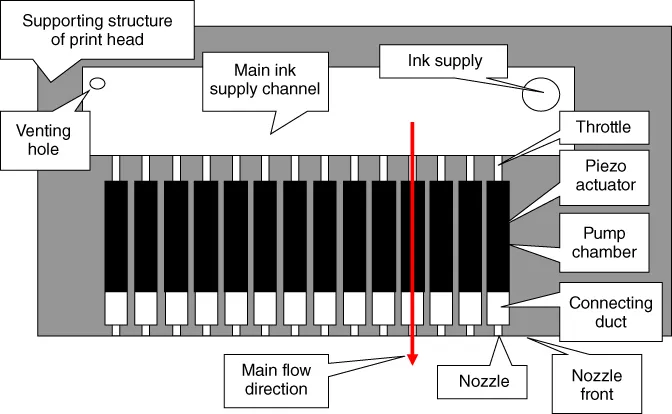

The present book is confined to piezo‐driven print heads. An example of such a print head is depicted in Figure 1.1.

Figure 1.1Schematic of piezo‐driven print head of the Helmholtz type.

A large number of pumps are integrated in a so‐called linear array print head. Linear array print heads can be stacked to form a matrix array print head. The dimensions of the print head are usually much smaller than the substrate to be printed. To cover the area of a substrate, several arrangements are possible:

- The print head is mounted on a stationary rig, and the substrate is placed on a so‐called XY stage; the substrate is printed in a number of subsequent X and Y motions of the stage.

- The print head is mounted on a carriage allowing for covering the substrate in width direction; the substrate is moved underneath the print head by a linear stage, whose motion is at right angles with respect to the motion of the carriage; the substrate is printed in a number of subsequent carriage motions and stepwise motion of the linear stage.

- A number of print heads are mounted on a stationary rig, such that the width of the substrate is covered; the substrate is placed on a linear stage. The substrate is printed in one continuous motion of the linear stage.

All the pumps are connected to the main supply channel through small channels, called throttles; such a set‐up of parts is referred to as the Helmholtz design [4]. The ink flows through the parallel‐placed chambers towards the nozzles. The wall of each pump is partly covered with a piezoelectric actuator; upon charging the actuator the volume of the pump chamber is changed causing a change in pressure. The ink is fed to the main supply channel through a feedhole, the ink supply. It is very important to fill the print head without any air bubbles; to visualize this need a venting hole is present. The nozzles are placed at a constant pitch; such a pitch is given in dots per inch (dpi) (1 dpi = 25.4 mm, 100 dpi = 0.254 mm = 254 μm).

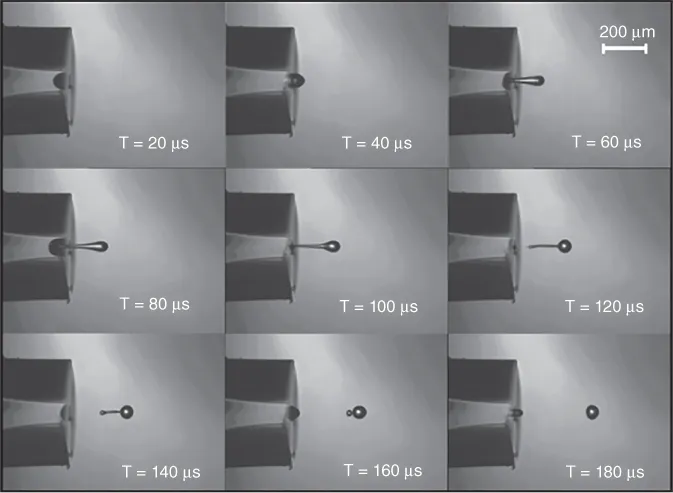

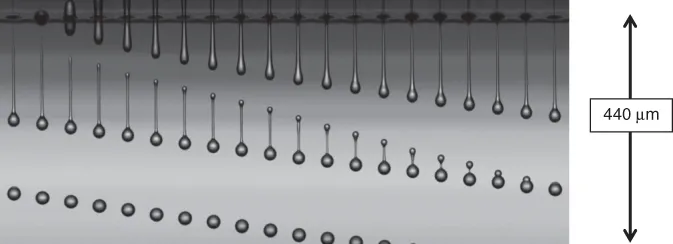

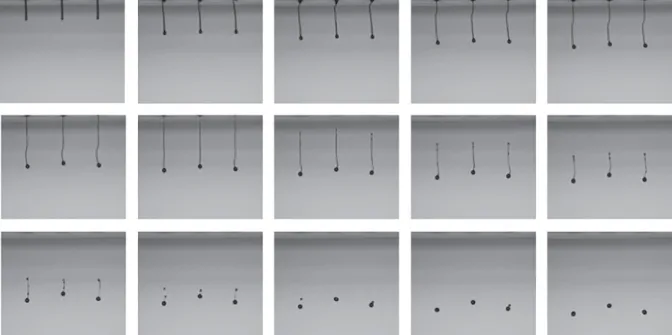

When the print head is driven by pulse‐wise actuation, droplet formation starts. A few examples are shown in the next three figures, displaying the jetting of a low viscosity ink, a high viscosity ink, and a viscoelastic ink (an ink made by dissolving a small amount of polymeric material in a low viscosity organic solvent) (Figures 1.2–1.4).

Figure 1.2Jetting of a low viscosity ink (water) from a Microdrop Autopipette AK 510 with a nozzle of 70 μm. The print head is driven with a negative pulse. Initially the meniscus retracts and then the droplet is formed. The droplet speed is about 2 m s−1; the droplet diameter is about equal to the nozzle diameter. Source: With permission from Microdrop GmbH Germany.

Figure 1.3Jetting of a high viscosity ink from a prototype print head (Océ Technologies, Venlo, the Netherlands) with a nozzle of 27 μm diameter and driven at 20 kHz with a positive pulse [5]. The ink is silicon oil with viscosity of 9.3 mPa s, density 930 kg m−3 and surface tension 20.2 mN m−1. The images were obtained by using a dual‐cavity Nd:Yag laser (wave length 532 nm) and fluorescent diffusor to remove any coherence in order to end up with images free of any speckle and interference fringes [6]. The pulse time of the flash has a duration of 8 ns. The picture is a concatenation of images taken with increasing delay from the leading edge of the pulse with steps of 2.5 μs. The droplet speed after the tail has merged with the main droplet is 3 m s−1. The droplet size measures 9.3 pl. Source: With permission from van der Meulen 2015 [5].

Figure 1.4Jetting of a viscoelastic ink. Series of photographs showing the evolution of the droplet formation of a viscoelastic ink from a Dimatix Galaxy 256 nozzle print head with 30 μm diameter nozzles [7]. The pitch between nozzles is 254 μm; the timing starts at 10 μs after the leading edge of the pulse, followed by images 10 μs apart in time. The shear viscosity of the ink has been tuned to 10 mPa s. The surface tension measures 30 mN m−1. The final droplet volume equals 15 pl, its speed 2 m s−1.

In order to understand the action of a piezo‐driven print head, several aspects must be considered:

- The mechanical design of it and the micro‐fluidic layout of the fluid path from reservoir all the way up to the nozzle.

- The properties of the ink like density ρ, surface tension γ, speed of sound c, and viscosity μ. For most of the cases to be discussed, these properties will be treated as constants. Ink may contain surfactants; during droplet formation the surface concentration of surfactants at the surface may be reduced, as diffusion from the bulk cannot cope with the fast extension of the surface during droplet formation [8]. Ink may also contain polymer additives that will cause the ink to behave viscoelastically. The fluid properties become rate and history dependent.

- The pulse shape. The electronics of the print head allow for flexibility in choosing the pulse shape.

This book is organized as follows:

In Chapter 2 the print head is modelled as a single cavity with a nozzle, also referred to as a single o...

Table of contents

- Cover

- Table of Contents

- Preface

- List of Symbols

- 1 Introduction

- 2 Single Degree of Freedom System

- 3 Two Degrees of Freedom System

- 4 Multi‐cavity Helmholtz Resonator Theory

- 5 Waveguide Theory of Single‐nozzle Print Head

- 6 Multi‐cavity Waveguide Theory

- 7 Droplet Formation

- 8 Droplet Flight, Evaporation, Impact, Spreading, Permeation, and Drying

- A Solving Algebraic Equations

- B Fourier Decomposition of a Pulse

- C Toroidal Co‐ordinate System

- Index

- End User License Agreement