Bioprocessing Piping and Equipment Design

A Companion Guide for the ASME BPE Standard

- English

- ePUB (mobile friendly)

- Available on iOS & Android

Bioprocessing Piping and Equipment Design

A Companion Guide for the ASME BPE Standard

About this book

The only comprehensive and authoritative reference guide to the ASME Bioprocessing Piping and Equipment (BPE) standard

This is a companion guide to the ASME Bioprocessing Piping and Equipment (BPE) Standard and explains what lies behind many of the requirements and recommendations within that industry standard. Following an introductory narrative to the Standard's early history, industry related codes and standards are explained; the design and engineering aspects cover construction materials, both metallic and nonmetallic; then components, fabrication, assembly and installation of piping systems are explored. Examination, Inspection and Testing then precede the ASME BPE certification process, concluding with a discussion on system design.

The author draws on many years' experience and insights from first-hand involvement in the field of industrial piping design, engineering, construction, and management, which includes the bioprocessing industry. The reader will learn why dimensions and tolerances, process instrumentation, and material selection play such an integral part in the manufacture of components and instrumentation.

This easy to understand and navigate guide will assist engineers (design, piping, chemical, etc.) who need to understand the basis for much of the Standard's content, as do the contractors and inspectors who have to meet and validate compliance with the BPE Standard.

Frequently asked questions

- Essential is ideal for learners and professionals who enjoy exploring a wide range of subjects. Access the Essential Library with 800,000+ trusted titles and best-sellers across business, personal growth, and the humanities. Includes unlimited reading time and Standard Read Aloud voice.

- Complete: Perfect for advanced learners and researchers needing full, unrestricted access. Unlock 1.4M+ books across hundreds of subjects, including academic and specialized titles. The Complete Plan also includes advanced features like Premium Read Aloud and Research Assistant.

Please note we cannot support devices running on iOS 13 and Android 7 or earlier. Learn more about using the app.

Information

1

Introduction, Scope, and General Requirements of the BPE

1.1 Introduction

1.2 Scope of the ASME BPE Standard

- Part GR—General Requirements: This section sets the tone and defines the scope and intent of the Standard. It defines terms that are specific to the bioprocessing industry and other terms that may have originated elsewhere and have been adopted by the BPE standard and given a definition that better relates to its intended use. It also provides a listing of documentation that is essential in meeting Food and Drug Association (FDA) compliance requirements. These are documents that would serve other industries well in proving verifiable and traceable evidence of material and workmanship.

- Part SD—Systems Design: Part SD creates a forum for lessons learned in the bioprocessing industry and also establishes standardized methodologies for achieving cleanable process systems. It provides discussion on how to design cleanability and sterility into a system and covers specific design issues with regard to instrumentation, hose assemblies, filtration, and other equipment. In addition to hydrostatic testing, this section also touches on testing fundamentals for spray balls, drainability, cleanability, and sterility. This section is one place in which the BPE Standard steps beyond the main focus of the B31.3 format. For instance, B31.3 is written and developed around the cornerstone of safety and system integrity, and the BPE, while also integrating safety and integrity, is focused mainly on providing acceptable criteria for system design. Since its inception, the SD subcommittee (SC) has taken on the task of researching accepted industry design practices that are currently being used in the bioprocessing industry. This, in an effort to validate, and, where necessary, rectify those largely unsubstantiated design practices and criteria while developing new and beneficial design criteria for adoption into the BPE Standard.

- Part DT—Dimensions and Tolerances for Process Components: Part DT has created standard dimensions for HP fittings. Prior to the availability of the BPE Standard and Part DT, there were no industry standard dimensions on fittings and valves and no common set of manufacturing tolerances. This meant that components from one manufacturer to the next were not necessarily interchangeable. This was a situation that had long presented a nightmare for many designers, forcing a situation in which all fittings had to be purchased from the same manufacturer to ensure compatibility. By working with the fitting manufacturers, they were able to create a standardized set of fittings. In addition they added a much needed option for the sulfur content of ASTM A270 stainless steel to support the use of autogenous orbital welding. This will be discussed in depth in Chapter 4 of this book.

- Part MJ—Materials Joining: For both metallic and nonmetallic material Part MJ touches on all aspects of the welding and bonding of pressure vessels, tanks, tubing, and fittings. It provides guidance on acceptable requirements related to material selection, inspection, examination, and testing. It also discusses joining processes and procedures, weld joint design and preparation, weld acceptance criteria, procedure and performance qualification, and documentation requirements. Several tables list weld acceptance criteria, and detailed graphics illustrate ac...

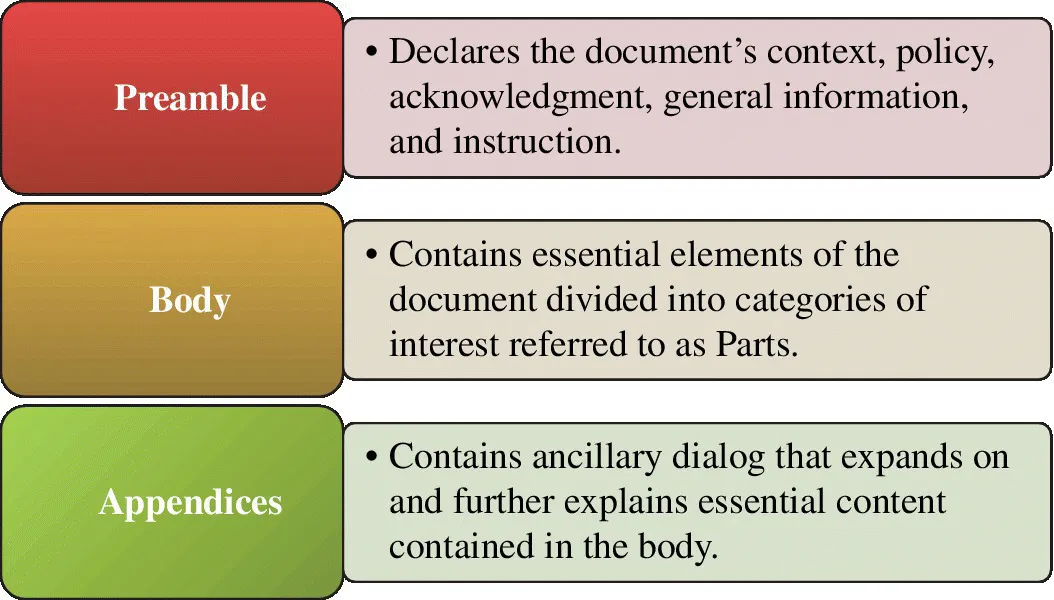

Table of contents

- Cover

- Title Page

- Table of Contents

- ASME BPE 2014

- List of Figures

- List of Tables

- List of Forms

- Series Preface

- Preface

- Acknowledgments

- About the Author

- 1 Introduction, Scope, and General Requirements of the BPE

- 2 Materials

- 3 Process Components

- 4 Fabrication, Assembly, and Installation

- 5 Examination, Inspection, and Testing

- 6 Equipment and Component Quality

- 7 Design

- 8 BPE Appendices

- Appendix A: Cleaning and Leak Testing Procedure

- Appendix B: Biotechnology Inspection Guide Reference Materials and Training Aids

- Appendix C: Guide to Inspections of High Purity Water Systems

- Appendix D: Guide to Inspections of Lyophilization of Parenterals

- Appendix E: Guide to Inspections and Validation of Cleaning Processes

- Appendix F: Guide to Inspections of Dosage Form Drug Manufacturer’s—CGMPR’s

- Appendix G: Guide to Inspections Oral Solutions and Suspensions

- Appendix H: Guide to Inspections of Sterile Drug Substance Manufacturers

- Appendix J: Guide to Inspections of Topical Drug Products

- Appendix K: BPE History—Letters and Notes

- Appendix L: Component Dimensions

- Further Reading

- Index

- End User License Agreement