Microbial Sensing in Fermentation

- English

- ePUB (mobile friendly)

- Available on iOS & Android

Microbial Sensing in Fermentation

About this book

A comprehensive review of the fundamental molecular mechanisms in fermentation and explores the microbiology of fermentation technology and industrial applications

Microbial Sensing in Fermentation presents the fundamental molecular mechanisms involved in the process of fermentation and explores the applied art of microbiology and fermentation technology. The text contains descriptions regarding the extraordinary sensing ability of microorganisms towards small physicochemical changes in their surroundings. The contributors — noted experts in the field — cover a wide range of topics such as microbial metabolism and production (fungi, bacteria, yeast etc); refined and non-refined carbon sources; bioprocessing; microbial synthesis, responses and performance; and biochemical, molecular and extra/intracellular controlling.

This resource contains a compilation of literature on biochemical and cellular level mechanisms for microbial controlled production and includes the most significant recent advances in industrial fermentation.

The text offers a balanced approach between theory and practical application, and helps readers gain a clear understanding of microbial physiological adaptation during fermentation and its cumulative effect on productivity. This important book:

- Presents the fundamental molecular mechanisms involved in microbial sensing in relation to fermentation technology

- Includes information on the significant recent advances in industrial fermentation

- Contains contributions from a panel of highly-respected experts in their respective fields

- Offers a resource that will be essential reading for scientists, professionals and researchers from academia and industry with an interest in the biochemistry and microbiology of fermentation technology

Written for researchers, graduate and undergraduate students from diverse backgrounds, such as biochemistry and applied microbiology, Microbial Sensing in Fermentation offers a review of the fundamental molecular mechanisms involved in the process of fermentation.

Tools to learn more effectively

Saving Books

Keyword Search

Annotating Text

Listen to it instead

Information

1

Biochemical Aspects of Microbial Product Synthesis: a Relook

1.1 Introduction

1.2 History of Industrial Production of Microbial Products

1.2.1 Advances of Biochemical Engineering and Their Effects on Global Market of Microbial Products

Table of contents

- Cover

- Table of Contents

- 1 Biochemical Aspects of Microbial Product Synthesis: a Relook

- 2 Cellular Events of Microbial Production: Important Findings So Far

- 3 Microbial Metabolism in a Refined Carbon Source: Generalities

- 4 Non‐refined Carbon Sources and Microbial Performance

- 5 Cellular versus Biochemical Control over Microbial Products

- 6 Pre‐Treatment of Alternative Carbon Source: How Does it Make Sense to Microorganism at Cellular Level?

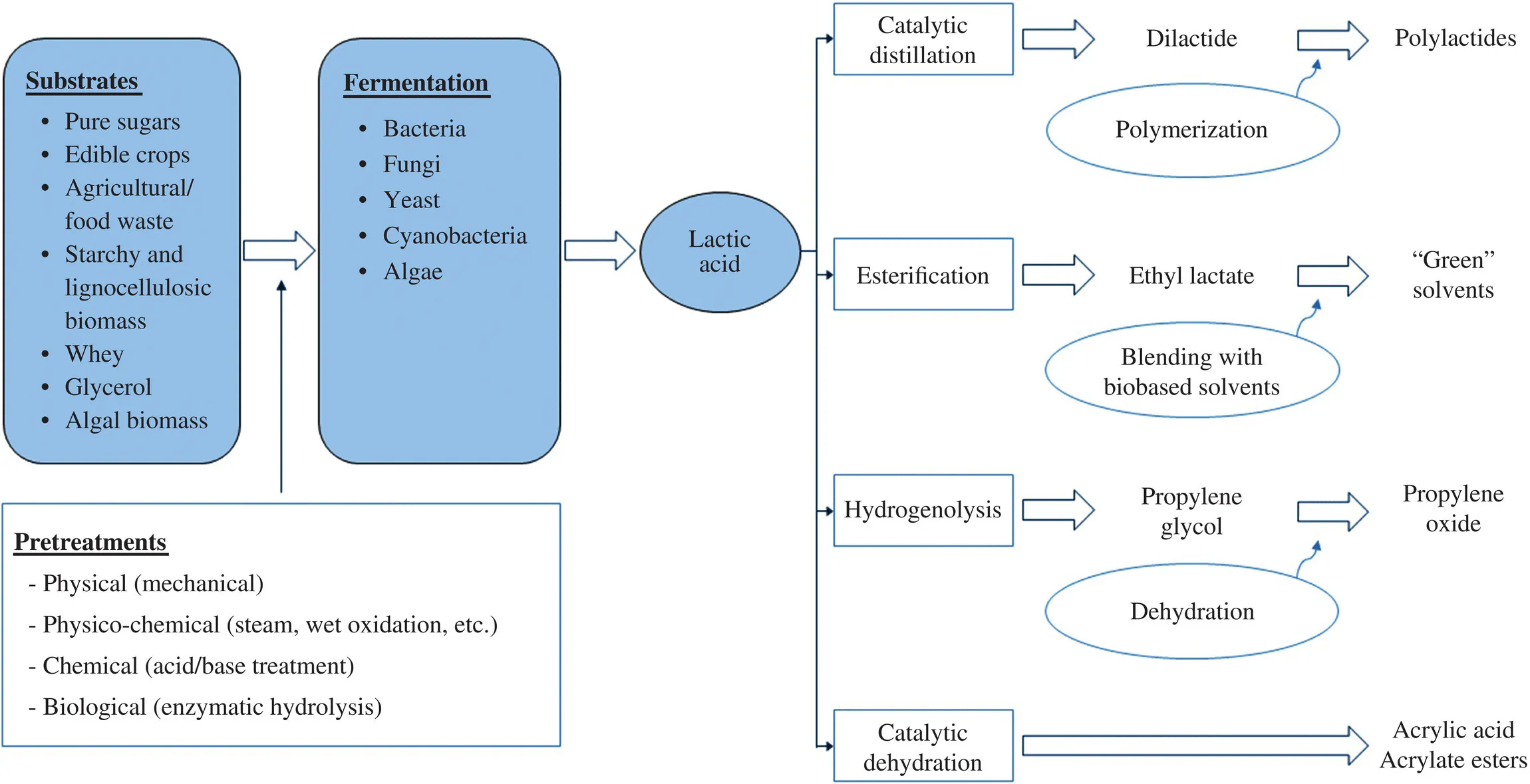

- 7 Microbial Metabolic Pathways in the Production of Valued‐added Products

- 8 Communication for a Collective Response to Environmental Stress

- 9 Biochemical and Cellular Events in Controlling Microbial Performance

- 10 Qualitative vs. Quantitative Control Over Microbial Products

- 11 Microbes and Their Products as Sensors in Industrially Important Fermentations

- 12 Practical Aspects and Case Studies of Industrial Scale Fermentation

- 13 Future Market and Policy Initiatives of New High Value Products

- Index

- End User License Agreement

Frequently asked questions

- Essential is ideal for learners and professionals who enjoy exploring a wide range of subjects. Access the Essential Library with 800,000+ trusted titles and best-sellers across business, personal growth, and the humanities. Includes unlimited reading time and Standard Read Aloud voice.

- Complete: Perfect for advanced learners and researchers needing full, unrestricted access. Unlock 1.4M+ books across hundreds of subjects, including academic and specialized titles. The Complete Plan also includes advanced features like Premium Read Aloud and Research Assistant.

Please note we cannot support devices running on iOS 13 and Android 7 or earlier. Learn more about using the app