- English

- ePUB (mobile friendly)

- Available on iOS & Android

Understanding Color Management

About this book

An accessible but technically rigorous guide to color management for all users in all market segments

Understanding Color Management, 2nd Edition explains the basics of color science as needed to understand color profiling software, color measuring instruments, and software applications, such as Adobe Photoshop and proofing RIPs. It also serves as a practical guide to International Color Consortium (ICC) profiles describing procedures for managing color with digital cameras, LCD displays, inkjet proofers, digital presses and web browsers and tablets. Updates since the first edition include new chapters on iPads, tablets and smartphones; home-cinema projection systems, as well as, with the industrial user in mind, new additional chapters on large-format inkjet for signage and banner printing, flexography, xerography and spot color workflows.

Key features:

- Managing color in digital cameras with Camera Raw and DNG.

- Step-by-step approach to using color management in Adobe Photoshop CC.

- M0, M1, M2 instrument measurement modes explained.

- Testing of low cost, iPhone color measuring instruments.

- Updated to include iccMAX (Version 5.0) ICC profiles.

- G7 calibration explained with practical examples.

- Conventional printing conditions described - SNAP, GRACoL, SWOP, Fogra, CRPC.

- New sections on Pantone EXTENDED GAMUT Guide.

- Introduction to XML for color management applications.

Understanding Color Management, 2nd Edition is a valuable resource for digital photographers, keen amateurs and end-users, graphic designers and artists, web masters, production and prepress operators and supervisors, color scientists and researchers, color consultants, and manufacturers. It is a must-have course text for college and university students of graphics arts, graphic communications, digital photography, print media, and imaging arts and sciences.

The Society for Imaging Science and Technology (imaging.org) is an international professional society whose mission is to keep members and others aware of the latest scientific and technological developments in the greater field of imaging. A major objective of the Wiley-IS&T series is to advance this goal at the professional level. The broad scope of the series focuses on imaging in all its aspects, with particular emphasis on digital printing, electronic imaging, image assessment and reproduction, image archiving and preservation, color science, pre-press technologies, and hybrid imaging systems.

Tools to learn more effectively

Saving Books

Keyword Search

Annotating Text

Listen to it instead

Information

1

Introduction

Objectives

- Explain and define color management.

- Describe the older, closed-loop method of color control.

- List the activities of the International Color Consortium (ICC).

- Describe the three Cs of color management – calibration, characterization and conversion.

- Introduce RGB/CMYK colorspaces and Yxy/L*a*b*.

- Introduce typical color management workflows.

- Describe the benefits of a color management system.

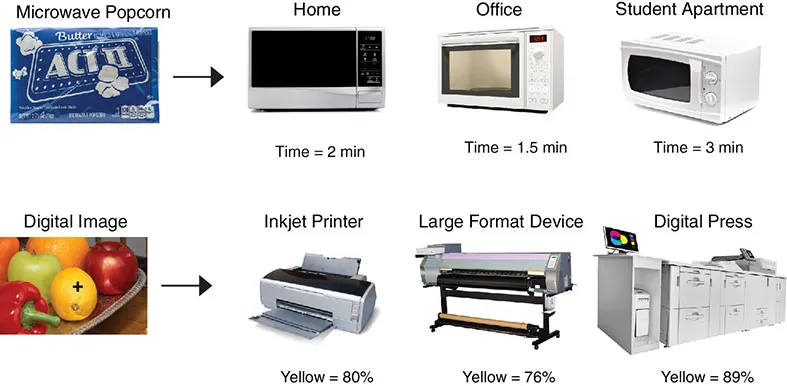

1.1 Why Do We Need Color Management?

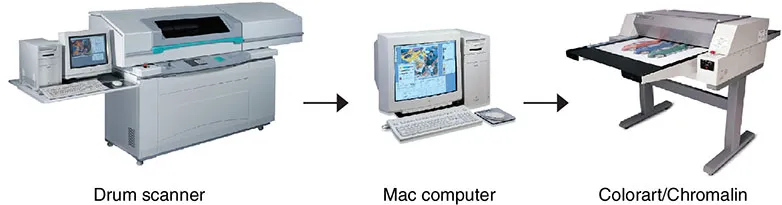

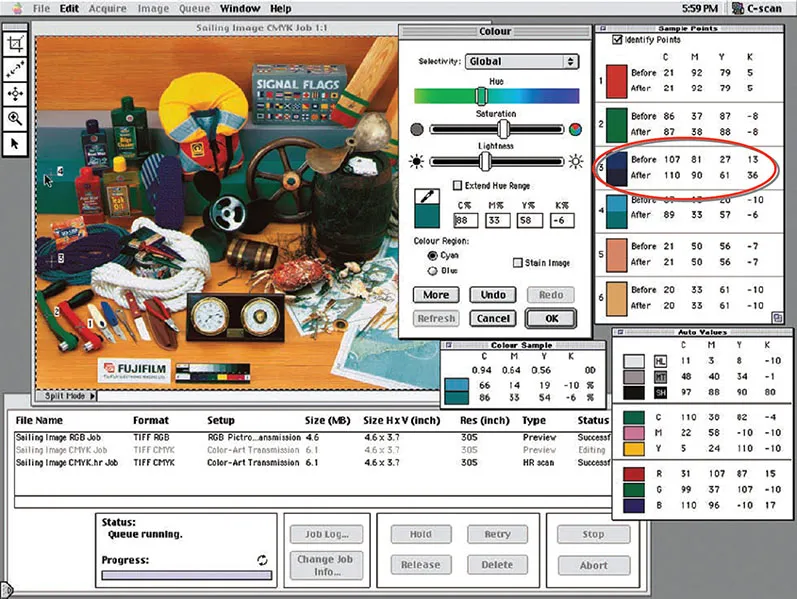

1.2 Closed-loop Color Control

Table of contents

- Cover

- Title Page

- Copyright

- Dedication

- Foreword to 2nd Edition

- Foreword to 1st Edition

- Preface

- Acknowledgments

- 1 Introduction

- 2 Principles of Light and Color

- 3 Color by Numbers

- 4 Measuring Instruments

- 5 Inside Profiles

- 6 Managing Color in Digital Cameras

- 7 Monitor Profiles

- 8 Press and Printer Profiling

- 9 Spot Colors & Expanded Gamut Printing

- 10 XML and Color Management

- 11 Color Management in Photoshop

- A Appendix

- Index

- End User License Agreement

Frequently asked questions

- Essential is ideal for learners and professionals who enjoy exploring a wide range of subjects. Access the Essential Library with 800,000+ trusted titles and best-sellers across business, personal growth, and the humanities. Includes unlimited reading time and Standard Read Aloud voice.

- Complete: Perfect for advanced learners and researchers needing full, unrestricted access. Unlock 1.4M+ books across hundreds of subjects, including academic and specialized titles. The Complete Plan also includes advanced features like Premium Read Aloud and Research Assistant.

Please note we cannot support devices running on iOS 13 and Android 7 or earlier. Learn more about using the app