eBook - ePub

Biodegradable and Biobased Polymers for Environmental and Biomedical Applications

- English

- ePUB (mobile friendly)

- Available on iOS & Android

eBook - ePub

Biodegradable and Biobased Polymers for Environmental and Biomedical Applications

About this book

This volume incorporates 13 contributions from renowned experts from the relevant research fields that are related biodegradable and biobased polymers and their environmental and biomedical applications.

Specifically, the book highlights:

- Developments in polyhydroxyalkanoates applications in agriculture, biodegradable packaging material and biomedical field like drug delivery systems, implants, tissue engineering and scaffolds

- The synthesis and elaboration of cellulose microfibrils from sisal fibres for high performance engineering applications in various sectors such as the automotive and aerospace industries, or for building and construction

- The different classes and chemical modifications of tannins

- Electro-activity and applications of Jatropha latex and seed

- The synthesis, properties and applications of poly(lactic acid)

- The synthesis, processing and properties of poly(butylene succinate), its copolymers, composites and nanocomposites

- The different routes for preparation polymers from vegetable oil and the effects of reinforcement and nano-reinforcement on the physical properties of such biobased polymers

- The different types of modified drug delivery systems together with the concept of the drug delivery matrix for controlled release of drugs and for antitumor drugs

- The use of nanocellulose as sustainable adsorbents for the removal of water pollutants mainly heavy metal ions, organic molecules, dyes, oil and CO 2

- The main extraction techniques, structure, properties and different chemical modifications of lignins

- Proteins and nucleic acids based biopolymers

- The role of tamarind seed polysaccharide-based multiple-unit systems in sustained drug release

Frequently asked questions

Yes, you can cancel anytime from the Subscription tab in your account settings on the Perlego website. Your subscription will stay active until the end of your current billing period. Learn how to cancel your subscription.

No, books cannot be downloaded as external files, such as PDFs, for use outside of Perlego. However, you can download books within the Perlego app for offline reading on mobile or tablet. Learn more here.

Perlego offers two plans: Essential and Complete

- Essential is ideal for learners and professionals who enjoy exploring a wide range of subjects. Access the Essential Library with 800,000+ trusted titles and best-sellers across business, personal growth, and the humanities. Includes unlimited reading time and Standard Read Aloud voice.

- Complete: Perfect for advanced learners and researchers needing full, unrestricted access. Unlock 1.4M+ books across hundreds of subjects, including academic and specialized titles. The Complete Plan also includes advanced features like Premium Read Aloud and Research Assistant.

We are an online textbook subscription service, where you can get access to an entire online library for less than the price of a single book per month. With over 1 million books across 1000+ topics, we’ve got you covered! Learn more here.

Look out for the read-aloud symbol on your next book to see if you can listen to it. The read-aloud tool reads text aloud for you, highlighting the text as it is being read. You can pause it, speed it up and slow it down. Learn more here.

Yes! You can use the Perlego app on both iOS or Android devices to read anytime, anywhere — even offline. Perfect for commutes or when you’re on the go.

Please note we cannot support devices running on iOS 13 and Android 7 or earlier. Learn more about using the app.

Please note we cannot support devices running on iOS 13 and Android 7 or earlier. Learn more about using the app.

Yes, you can access Biodegradable and Biobased Polymers for Environmental and Biomedical Applications by Susheel Kalia,Luc Avérous in PDF and/or ePUB format, as well as other popular books in Technologie et ingénierie & Ingénierie de la chimie et de la biochimie. We have over one million books available in our catalogue for you to explore.

Information

Chapter 1

Biomedical Applications for Thermoplastic Starch

Abstract

Thermoplastic starch (TPS) emerged recently as a new polymeric material based on biodegradable and renewable resources. Since its beginning in the 1990s, several researchers described the use of TPS for biomedical applications, which increased recently due to new TPS-based materials such as blends with other polymers, composites and nanocomposites. Its non-toxic, resorbable and biodegradable characteristics make TPS a key material for biomedical applications, allowing its use in implantable materials, opening a new field of research. In this chapter we introduce TPS and we describe the most recent research on its applications and new developments in biomedical and pharmaceutical areas.

Keywords: Thermoplastic starch, processing, biomedical in vivo tests, scaffolds, resorbable material

1.1 Starch as Source of Materials in the Polymer Industry

Thermoplastic starch (TPS) emerged as new class of biodegradable materials in the 1990s and quickly become one of the most studied polymer system in the field of biodegradable materials derived from renewable resources [1–9]. One reason for this interest is the fact that starch is one of the few natural polymers that can be used directly as a thermoplastic material without any chemical modification [9], with possible uses in package and in food and biomedical industries. In this chapter we describe the approach for TPS preparation, as well as its blends, some methods for chemical modification of starch and the most advanced materials prepared from starch for application in pharmaceutical and biomedical fields.

1.2 Starch in Plastic Materials and Thermoplastic Starch

The use of starch in compositions in the plastic industry is not new. Since the 1960s starch has been used in its native form as granule or gelatinized in compositions with other polymers such as rubber [10, 11], polyvinyl chloride (PVC) [10, 12] and in low-density polyehylene (LDPE) as filler [13]. However, further investigations into these processes were not undertaken due to several problems such as the need of drying and poor adhesion of the hydrophilic starch granules to the high hydrophobic polymer matrix.

Relative success in producing films by casting a dispersion of gelatinized starch and poly(ethylene-co-acrylic acid) (EAA) was described by Otey and co-workers [10, 14–16]. However, the high costs involved limited its application in high extension. Other attempts to use starch were also described by the same research group. The main examples consisted of blends of starch and poly(ethylene-co-acrylic acid), which after drying were processed by extrusion-blowing. This blends where plasticized with sorbitol, glycerol, urea, starch-based polyols [17]. These materials where partially biodegradable, which also limited its application.

The fundamentals of TPS preparation have long become well-known because starch gelatinization leads to the same kind of material. The process can be divided into two conditions, in excess of water, and in low water concentrations.

When native starch is heated above a characteristic temperature (known as the gelatinization temperature), in excess of water or of another solvent such as liquid ammonia, formamide, dimethyl sulfoxide and others, it undergoes an irreversible order-disorder transition known as gelatinization or destructuration [9]. The process involves two steps: hydration limited by the diffusion of the solvent through the granule, and melting of the starch crystallites [18, 19]. The phenomenon is characterized either by a large excess of water in a single endotherm peak observed by DTA or DSC, corresponding to the gelatinization temperature; or by an endotherm event, at a higher temperature, in which the maximum temperature depends on the water concentration attributed to the melting of the starch crystallites. When water concentration is intermediate between the gelatinization and the melting, two endothermic transitions are observed. The same final results can be obtained when TPS is produced in limited amounts of water or in the presence of a high boiling point hydroxyl compounds.

Thermoplastic starch behaves as a conventional thermoplastic and may be repeatedly softened and hardened, so that it becomes amenable to moulding/shaping by the action of heat and shear forces. This behaviour allows TPS processing with commonly techniques used in the plastic industry — a very attractive feature, since a low additional investment is required to achieve effective industrial use [1, 20, 21]. The temperature for TPS processing depends on the proportions of starch/plasticizer and, in general, it is between 120 °C and 160 °C. Expanded materials can be obtained when water is used alone or in combination with starch to produce TPS.

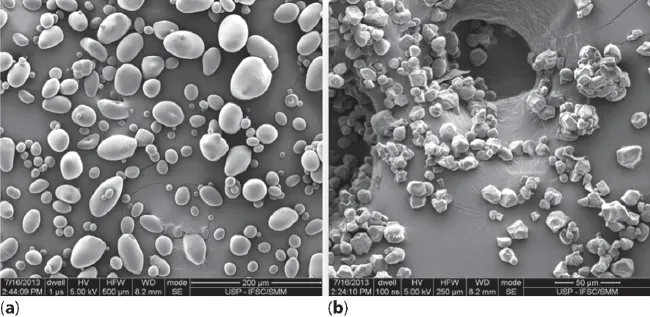

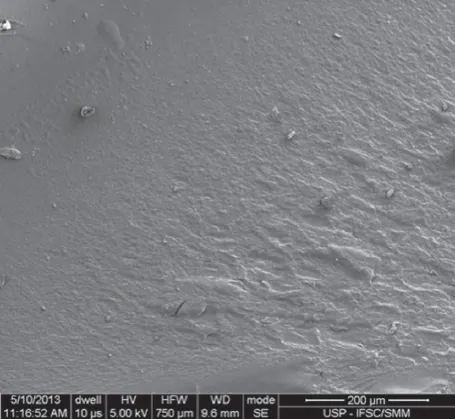

Starch granules structure is completely destroyed when it is plasticized to produce TPS. The scanning electron microscopy (SEM) images in Figure 1.1 shows the morphology of native starch granules from two different food sources, potato (a) and regular corn starch (b). Figure 1.2 shows the smooth surface of a TPS film evidencing the complete granules disruption. TPS is processed conventionally by extrusion in wires, strips or in pellets. Figure 1.3 shows samples of extruded TPS in strips and wires before pellet cutting.

Figure 1.1 Starch granules from potato (a – scale correspond to 200 µm) and corn (b- scale correspond to 50 µm).

Figure 1.2 Scanning electron microscopy of a TPS film.

Figure 1.3 Extruded TPS (A) and an extruded sheet of TPS (B).

The choices of plasticizer type and concentration are of fundamental importance not only for the processing conditions, but also for the final properties of the material. These can vary from a rigid and fragile material, to a soft and rubbery material at room temperature [22]. The most common plasticizer for starch is glycerol [8, 9] however other such as urea [3], fructose [23], xylitol, sorbitol, maltitol [8, 22, 24], glycols (EG, TEG, PG, PEG) [9], ethanolamine [25] and formamide [26] have also been used. In essence, the plasticizer is any substance capable of forming stable hydrogen bonds at the processing temperatures used for TPS production. The presence of water in the compositions, which works as a “processing” plasticizer is recommended, since it improves the destructuration efficiency, decreases melt viscosity and consequently, reduces starch degradation rate during its processing [27, 28].

Alternatively, starch may be dried before processing and the processes conducted in the presence of glycerol, resulting in materials with superior thermoplastic feature [29].

Although the process to produce TPS is based on the destruction of the crystalline structure of the native starch, TPS is not completely amorphous and undergoes crystallization, especially when stored at temperatures above its glass transition temperature. Crystallization of starch in TPS leads to crystalline forms different from the native starch granule, being the most important the B-, V- and E-forms. V- and E-types can be observed just after extrusion because they are generated during processing [30, 31]. Two sub types of V-type exist, the anhydrous Va-type for materials containing low moisture concentrations and the hydrated form Vh-type for materials containing higher moisture concentrations. The E-type occurs only in samples with low moisture concentrations [32], B-type crystallinity is similar to that observed in native starch from potato and tapioca and is formed slowly during storage [6].

Materials based on starch are biodegradable and biocompatible, widely available at low cost, and irreplaceable in a wide range of applications due to their unique properties. The search for new applications of starch is fast increasing in the last years, and the biomedical uses of such materials represents an important advance in the research field [33].

1.3 Uses of Starch and TPS in Biomedical and Pharmaceutical Fields

Starch is used in packaging, food and pharmaceutical industry for decades and its application field is growing because its singular properties, specially its physicochemical properties, biocompatibility and biodegradability [34, 35]. In pharmaceutical industry starch is an important functional ingredient for formulations of tablets, capsules [36], coatings [37], subcutaneous implants [38] and matrix for drug release systems [33, 39, 40].

Studies related to applications of starch in pharmaceutical and biomedical areas progressed gradually. The earliest focus of the scientific reports regards to the study of food and pharmaceutical uses of starch in its natural form as extracted from vegetables. These studies included structure determination, morphology characterization and the properties as food and drug modifier. In the food industry, starch is extensively used as a thickener, while in the pharmaceutical industry it is extensively used as excipient. However, its special properties have widened its range of applications. Current research is directed toward the development of starch-based materials aiming the improvement of pharmaceutical, cosmetics, and healthy & care formulations. Some important research have been developed with respect to the use of starch as a biosorbable material for temporary implants. The features that make starch interesting for these applications include the combination of its mechanical properties and its hydrophilic and resorbable characters, allowing its use inside human and animal body as implants and other devices. The high degree of chemical functionality of starch, due to the presence of hydroxyl groups allows its chemical modification, generating a wide range of materials with interesting properties for use in biomedical and pharmaceutical areas.

Apart from the demand it enjoys in the research, field, starch has also found a consolidated demand in pharmaceutical industry, mainly for use as excipient in solid formulations like tablets and powder presentations. However, many starch-based products have been developed for uses in tissue engineering, drug delivery and wound healing, including its chemical modification.

1.3.1 Native Starch (Granule) as Pharmaceutical Excipient

Excipients are usually inert and inactive ingredients that make up the vehicle or matrix, used as basic drug carriers in pharmacological formulations. Despite this inactivity they nevertheless fulfil secondary functions as stabilizers, preservatives, buffers, diluents, binders, disintegrants, lubricants, dye and-or flavouring agents. The conventional concept of excipient as a simple, chemically and pharmacologically inert vehicle of a formulation has been changing to an essential functional agent that optimizes and improves the performance of the drug [34]. Excipients can interact with the active molecules from the formulation and affect its dissolution, absorption and bioavailability. In this venue, the drug delivery technology has been improving the pharmaceutical systems and drug bioavailability. Excipients can also help the manufacture processing and disintegration, preventing the fast release of the drug. The hole of starch is remarkable as a pharmaceutical excipient mainly as a diluent and disintegrant agent in tablets and capsules formulations when used as unmodified granules and as a binder, when it is pre-gelatinized.

Several research strategies that have emerged recently as the dominant trends in thermoplastic starch-based materials for biomedical uses, and the use of blends for the development of biocompatible materials and its preliminar tests in biological in vivo systems are described here.

1.3.2 Gelatinized and Thermoplastic Starch in Biomedical Application

Regarding the use of starch for the manufacture of capsules for drug delivery, thermoplastic starch-based polyvinyl alcohol material obtained by extrusion are noteworthy. They were developed as a potential substitute for soft gelatin capsules [41]. Gelatin has been used for decades for capsules preparation because of its physicochemical properties. One of the drawbacks of gelatin for hydrophilic lipid-based formulations is the high content of water of the matrix (up to 35%), which migrate...

Table of contents

- Cover

- Half Title page

- Title page

- Copyright page

- Preface

- Chapter 1: Biomedical Applications for Thermoplastic Starch

- Chapter 2: Polyhydroxyalkanoates: The Application of Eco-Friendly Materials

- Chapter 3: Cellulose Microfibrils from Natural Fiber Reinforced Biocomposites and its Applications

- Chapter 4: Tannins: A Resource to Elaborate Aromatic and Biobased Polymers

- Chapter 5: Electroactivity and Applications of Jatropha Latex and Seed

- Chapter 6: Characteristics and Applications of PLA

- Chapter 7: PBS Makes its Entrance into the Family of Biobased Plastics

- Chapter 8: Development of Biobased Polymers and Their Composites from Vegetable Oils

- Chapter 9: Polymers as Drug Delivery Systems

- Chapter 10: Nanocellulose as a Millennium Material with Enhancing Adsorption Capacities

- Chapter 11: Towards Biobased Aromatic Polymers from Lignins

- Chapter 12: Biopolymers – Proteins (Polypeptides) and Nucleic Acids

- Chapter 13: Tamarind Seed Polysaccharide-based Multiple-Unit Systems for Sustained Drug Release

- Index