Roll-to-Roll Manufacturing

Process Elements and Recent Advances

- English

- ePUB (mobile friendly)

- Available on iOS & Android

Roll-to-Roll Manufacturing

Process Elements and Recent Advances

About this book

A single-volume resource featuring state-of-the art reviews of key elements of the roll-to-roll manufacturing processing methodology

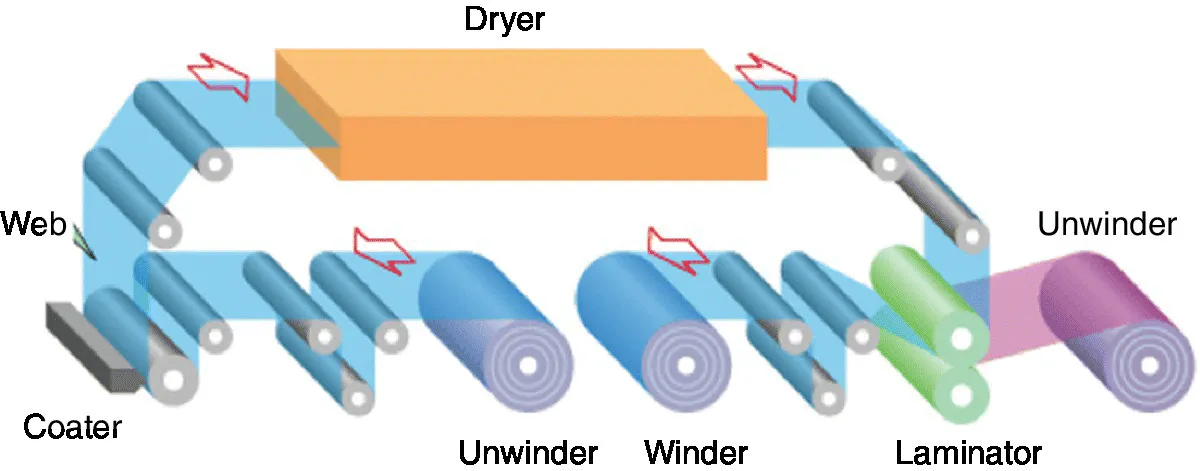

Roll-to-roll (R2R) manufacturing is an important manufacturing technology platform used extensively for mass-producing a host of film-type products in several traditional industries such as printing, silver-halide photography, and paper. Over the last two decades, some of the methodologies and know-how of R2R manufacturing have been extended and adapted in many new technology areas, including microelectronics, display, photovoltaics, and microfluidics. This comprehensive book presents the state-of-the-art unit operations of the R2R manufacturing technology, providing a practical resource for scientists, engineers, and practitioners not familiar with the fundamentals of R2R technology.

Roll-to-Roll Manufacturing: Process Elements and Recent Advances reviews new developments in areas such as flexible glass, display, and photovoltaics and covers a number of process innovations implemented recently to extend and improve the capabilities of traditional R2R lines. It covers such topics as: coating and solidification processes, in-line vacuum deposition, drying, web handling and winding, polymer film substrates, novel hybrid composite films, flexible solar cells and more. Additionally, this book:

- Examines key elements (unit operations) of the R2R technology, and discusses how these elements are utilized and integrated to achieve desired process efficiencies in a host of applications.

- Illustrates several established and novel application areas where R2R processing is utilized in current or future products.

- Discusses process design methodology and key advantages of R2R manufacturing technology over batch or sheet-to-sheet operations.

Roll-to-Roll Manufacturing: Process Elements and Recent Advances is an ideal book for undergraduate and graduate students in various science and engineering disciplines, as well as for scientists, engineers, and technical and business leaders associated in any way with the development, commercialization, and manufacture of a variety of film products.

Tools to learn more effectively

Saving Books

Keyword Search

Annotating Text

Listen to it instead

Information

1

Roll‐to‐Roll Manufacturing: An Overview

1.1 Introduction

Table of contents

- Cover

- Title Page

- Table of Contents

- Preface

- 1 Roll‐to‐Roll Manufacturing: An Overview

- 2 Coating and Solidification

- 3 Drying of Polymer Solutions: Modeling and Real‐Time Tracking of the Process

- 4 In‐Line Vacuum Deposition

- 5 Web Handling and Winding

- 6 Polymer Film Substrates for Roll‐to‐Roll Manufacturing: Process–Structure–Property Relationships

- 7 Curl Effects in Roll‐to‐Roll Operations

- 8 Roll‐to‐Roll Processing of Glass

- 9 Novel Hybrid Composite Films by Roll‐to‐Roll Processing

- 10 Roll‐to‐Roll Manufacturing of Flexible Displays

- 11 Flexible Solar Cells

- 12 Field‐Assisted Self‐Assembly of Nanocomposite Films: A Roll‐to‐Roll Approach

- Index

- End User License Agreement

Frequently asked questions

- Essential is ideal for learners and professionals who enjoy exploring a wide range of subjects. Access the Essential Library with 800,000+ trusted titles and best-sellers across business, personal growth, and the humanities. Includes unlimited reading time and Standard Read Aloud voice.

- Complete: Perfect for advanced learners and researchers needing full, unrestricted access. Unlock 1.4M+ books across hundreds of subjects, including academic and specialized titles. The Complete Plan also includes advanced features like Premium Read Aloud and Research Assistant.

Please note we cannot support devices running on iOS 13 and Android 7 or earlier. Learn more about using the app