Improving Product Reliability and Software Quality

Strategies, Tools, Process and Implementation

- English

- ePUB (mobile friendly)

- Available on iOS & Android

Improving Product Reliability and Software Quality

Strategies, Tools, Process and Implementation

About this book

The authoritative guide to the effective design and production of reliable technology products, revised and updated

While most manufacturers have mastered the process of producing quality products, product reliability, software quality and software security has lagged behind. The revised second edition of Improving Product Reliability and Software Quality offers a comprehensive and detailed guide to implementing a hardware reliability and software quality process for technology products. The authors – noted experts in the field – provide useful tools, forms and spreadsheets for executing an effective product reliability and software quality development process and explore proven software quality and product reliability concepts.

The authors discuss why so many companies fail after attempting to implement or improve their product reliability and software quality program. They outline the critical steps for implementing a successful program. Success hinges on establishing a reliability lab, hiring the right people and implementing a reliability and software quality process that does the right things well and works well together. Designed to be accessible, the book contains a decision matrix for small, medium and large companies. Throughout the book, the authors describe the hardware reliability and software quality process as well as the tools and techniques needed for putting it in place. The concepts, ideas and material presented are appropriate for any organization. This updated second edition:

- Contains new chapters on Software tools, Software quality process and software security.

- Expands the FMEA section to include software fault trees and software FMEAs.

- Includes two new reliability tools to accelerate design maturity and reduce the risk of premature wearout.

- Contains new material on preventative maintenance, predictive maintenance and Prognostics and Health Management (PHM) to better manage repair cost and unscheduled downtime.

- Presents updated information on reliability modeling and hiring reliability and software engineers.

- Includes a comprehensive review of the reliability process from a multi-disciplinary viewpoint including new material on uprating and counterfeit components.

- Discusses aspects of competition, key quality and reliability concepts and presents the tools for implementation.

Written for engineers, managers and consultants lacking a background in product reliability and software quality theory and statistics, the updated second edition of Improving Product Reliability and Software Quality explores all phases of the product life cycle.

Tools to learn more effectively

Saving Books

Keyword Search

Annotating Text

Listen to it instead

Information

Part I

Reliability and Software Quality – It's a Matter of Survival

1

The Need for a New Paradigm for Hardware Reliability and Software Quality

1.1 Rapidly Shifting Challenges for Hardware Reliability and Software Quality

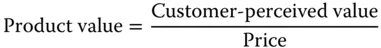

1.2 Gaining Competitive Advantage

1.3 Competing in the Next Decade – Winners Will Compete on Reliability

- Higher first‐pass yield in test,

- Less material scrap,

- Less product rework (which helps to lower product cost and improve product reliability),

- Fewer field failures,

- Reduced warranty costs (this saving can be passed onto the consumer to provide a competitive price advantage),

- Lower risk of recall,

- Superior designs that are easier to manufacture.

1.4 Concurrent Engineering

Table of contents

- Cover

- Table of Contents

- About the Authors

- List of Figures

- List of Tables

- Series Editor's Foreword

- Series Foreword Second Edition

- Series Foreword First Edition

- Foreword First Edition

- Preface Second Edition

- Preface First Edition

- Acknowledgments

- Glossary

- Part I: Reliability and Software Quality – It's a Matter of Survival

- Part II: Unraveling the Mystery

- Part III: Steps to Successful Implementation

- Part IV: Reliability and Quality Process for Product Development

- Appendix A:

- Appendix B:

- Index

- End User License Agreement

Frequently asked questions

- Essential is ideal for learners and professionals who enjoy exploring a wide range of subjects. Access the Essential Library with 800,000+ trusted titles and best-sellers across business, personal growth, and the humanities. Includes unlimited reading time and Standard Read Aloud voice.

- Complete: Perfect for advanced learners and researchers needing full, unrestricted access. Unlock 1.4M+ books across hundreds of subjects, including academic and specialized titles. The Complete Plan also includes advanced features like Premium Read Aloud and Research Assistant.

Please note we cannot support devices running on iOS 13 and Android 7 or earlier. Learn more about using the app