- English

- ePUB (mobile friendly)

- Available on iOS & Android

eBook - ePub

About this book

This book has been written to address many of the developments since the 1 st Edition which have improved how companies survey and select new sites, evaluate acquisitions, or expand their existing facilities. This book updates the appendices containing both the recommended separation distances and the checklists to help the teams obtain the information they need when locating the facility within a community, when arranging the processes within the facility, and when arranging the equipment within the process units.

Frequently asked questions

Yes, you can cancel anytime from the Subscription tab in your account settings on the Perlego website. Your subscription will stay active until the end of your current billing period. Learn how to cancel your subscription.

No, books cannot be downloaded as external files, such as PDFs, for use outside of Perlego. However, you can download books within the Perlego app for offline reading on mobile or tablet. Learn more here.

Perlego offers two plans: Essential and Complete

- Essential is ideal for learners and professionals who enjoy exploring a wide range of subjects. Access the Essential Library with 800,000+ trusted titles and best-sellers across business, personal growth, and the humanities. Includes unlimited reading time and Standard Read Aloud voice.

- Complete: Perfect for advanced learners and researchers needing full, unrestricted access. Unlock 1.4M+ books across hundreds of subjects, including academic and specialized titles. The Complete Plan also includes advanced features like Premium Read Aloud and Research Assistant.

We are an online textbook subscription service, where you can get access to an entire online library for less than the price of a single book per month. With over 1 million books across 1000+ topics, we’ve got you covered! Learn more here.

Look out for the read-aloud symbol on your next book to see if you can listen to it. The read-aloud tool reads text aloud for you, highlighting the text as it is being read. You can pause it, speed it up and slow it down. Learn more here.

Yes! You can use the Perlego app on both iOS or Android devices to read anytime, anywhere — even offline. Perfect for commutes or when you’re on the go.

Please note we cannot support devices running on iOS 13 and Android 7 or earlier. Learn more about using the app.

Please note we cannot support devices running on iOS 13 and Android 7 or earlier. Learn more about using the app.

Yes, you can access Guidelines for Siting and Layout of Facilities by in PDF and/or ePUB format, as well as other popular books in Technology & Engineering & Chemical & Biochemical Engineering. We have over one million books available in our catalogue for you to explore.

Information

Edition

21

INTRODUCTION

1.1 OBJECTIVES

This guideline describes in sequence how the risks associated with hazardous materials and processes are managed when siting a facility, when arranging new or modified process units within a facility, and then when arranging the new or modified equipment within the process unit. It provides a starting point for companies to help make decisions on how to select a facility’s location, how to recognize and assess the facility’s long-term risks, and how to lay out the processing units and the equipment within the facility. The location of and the arrangement of process units and associated equipment for a petrochemical facility is described to help illustrate how on-site and off-site risks can be reduced when locating the facility, and how on-site risks can be reduced when arranging process units within a facility or equipment within a process unit. This guideline’s appendices include additional references, tables listing recommended process unit and equipment separation distances for fire scenarios compiled from industry practices, guidelines, checklists, and standards for selecting the location of facilities (their siting) and for selecting the distances between processes and equipment (their layout within the selected location).

The objectives of this guideline include:

- Applying a Risk Based Process Safety (RBPS) approach [CCPS 2007a] and providing guidance when selecting the location of a facility handling hazardous materials and energies, when arranging the process units within the facility, and when arranging the equipment within the process units (the “siting” and the “layout” of the facility),

- Providing guidance for selecting the location selection team, taking into account the type of facility and the local conditions (e.g., geographical, weather, etc.)

- Applying inherently safer design principles when selecting a facility location, when locating process units within a facility (their “blocks”) and when locating the equipment within the process units,

- Providing guidance on reducing the risks associated with both the potential off-site and on-site consequences, helping reduce a facility’s life cycle costs, and

- Providing guidance when making changes to existing facilities.

The scope of this guideline is for onshore, outside (“open air”) refining, petrochemical and chemical operations that handle, process, or store hazardous materials, including:

- Large and small facilities

- New and existing facilities

Although this guideline addresses some of the design issues for structures that enclose process units, it beyond the scope to address the distances between process equipment within these enclosed structures. In addition, this guideline refers to but does not detail the quantitative methods designed to evaluate the impacts on personnel and structures after an outside loss of containment of hazardous materials. These methods are described in more detail in other references [e.g., API RP 752, API RP 753, API RP 756, CCPS 1999b, CCPS 2009a, and CCPS 2012b].

The information provided in this guideline will help those deciding: 1) on locations for new facilities (a “location selection” team); and, 2) on the layout and separation distances of process units and their associated equipment within the facility (“process unit layout” and “equipment layout” teams). It is important that the decisions made by these teams are consistent with the company’s risk tolerance levels, since locating facilities and the processes within a facility may affect potential risks to the facility’s infrastructure, to the facility’s security, to the surrounding community, and to the environment.

The costs, complexity and safety of process operations and maintenance are highly dependent on the location of the facility and the layout of the process units and their equipment within the facility. Since building inherently safer design into a facility’s layout can help reduce both the operational costs and the process complexity, it makes sense to locate a facility and choose the layout for the equipment using inherently safer design principles early when designing the process. Note that changing the process design may not be feasible once the project is approved since such changes may delay the approved project schedule and business objectives to meet the projected market demand. Although it is beyond the scope of this guideline to address cost-benefit analyses, there may be costly design changes once the facility is constructed if the siting and layout issues are not addressed early. Optimal siting of facilities, and subsequent process unit and equipment layout within them, helps minimize material and construction costs, and more importantly, helps minimize losses throughout the facility’s life cycle with potentially less physical/structural damages and decreased business interruption time.

1.2 A SITING AND LAYOUT APPROACH

This guideline describes a preferred approach used to ensure that new or modified facilities consider essential issues early in the process of searching for the location. This can help avoid issues that may become costly short-term project-related design changes, may involve costly changes during construction, or may become costly long term operating and maintenance issues once the facility is built. This siting philosophy begins first with a review of the material and processing hazards, such as toxicity, flammability, explosivity, reactivity, or a combination of these hazards. Other potential hazards should also be considered since they may be unacceptable to the surrounding community, such as odors, loud noises, or the light from flares.

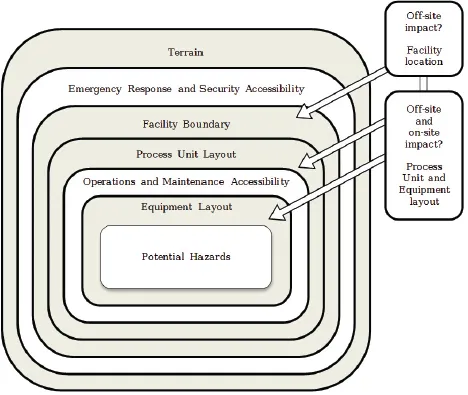

Once the types of hazards have been identified, their potential off-site and on-site impacts can be addressed. This step includes determining how the local terrain affects the release scenarios (the ultimate impact on the surrounding community), emergency responder accessibility, and security accessibility (the risks at the facility’s boundary). At the same time, the layout of the process units and associated areas within the facility, such as storage tank areas or flares, should be arranged to reduce risks. The layout of the equipment, including both their orientation and the separation distances between them, may affect both off-site and on-site consequences, as well. Since the layout of equipment can affect day-to-day operations, it is important to address the balance between reduced or increased distances and the impact on accessibility when evaluating the on-site consequences. The illustration in Figure 1.1 provides a high level view of this inter- related approach, beginning with understanding the hazards and potential consequences, understanding the effects of the location’s terrain, and then understanding both the potential off- site and on-site impacts due to process unit and equipment layout and accessibility.

Figure 1.1. A Siting and Layout Approach

1.3 HOW TO USE THIS GUIDELINE

This guideline is written to provide a starting point when deciding on locations for new facilities. Once the location has been determined, guidance is provided when evaluating and determining the layout of, and separation distances between, process units and their associated equipment wit...

Table of contents

- COVER

- PRAISE

- TITLE PAGE

- COPYRIGHT

- DEDICATION

- ACRONYMS AND ABBREVIATIONS

- GLOSSARY

- ACKNOWLEDGMENTS

- FOREWORD

- PREFACE

- 1 INTRODUCTION

- 2 OVERVIEW OF BENEFITS

- 3 IDENTIFYING THE PROCESS HAZARDS AND RISKS

- 4 SELECTING A FACILITY LOCATION

- 5 SELECTING THE PROCESS UNIT LAYOUT WITHIN A FACILITY

- 6 SELECTING THE EQUIPMENT LAYOUT WITHIN A PROCESS UNIT

- 7 MANAGING CHANGES

- 8 CASE HISTORIES

- 9 REFERENCES

- 10 APPENDICES

- APPENDIX A. ADDITIONAL SITING AND LAYOUT REFERENCES

- APPENDIX B. CCPS RECOMMENDED DISTANCE TABLES FOR SITING AND LAYOUT OF FACILITIES

- APPENDIX C. CHECKLIST FOR IDENTIFYING THE PROCESS HAZARDS AND RISKS

- APPENDIX D. CHECKLIST FOR SELECTING A FACILITY LOCATION

- APPENDIX E. CHECKLIST FOR SELECTING THE PROCESS UNIT LAYOUT WITHIN A FACILITY

- APPENDIX F. CHECKLIST FOR SELECTING THE EQUIPMENT LAYOUT WITHIN A PROCESS UNIT

- INDEX

- EULA