- English

- ePUB (mobile friendly)

- Available on iOS & Android

eBook - ePub

About this book

This book provides designers and operators of chemical process facilities with a general philosophy and approach to safe automation, including independent layers of safety. An expanded edition, this book includes a revision of original concepts as well as chapters that address new topics such as use of wireless automation and Safety Instrumented Systems. This book also provides an extensive bibliography to related publications and topic-specific information.

Frequently asked questions

Yes, you can cancel anytime from the Subscription tab in your account settings on the Perlego website. Your subscription will stay active until the end of your current billing period. Learn how to cancel your subscription.

No, books cannot be downloaded as external files, such as PDFs, for use outside of Perlego. However, you can download books within the Perlego app for offline reading on mobile or tablet. Learn more here.

Perlego offers two plans: Essential and Complete

- Essential is ideal for learners and professionals who enjoy exploring a wide range of subjects. Access the Essential Library with 800,000+ trusted titles and best-sellers across business, personal growth, and the humanities. Includes unlimited reading time and Standard Read Aloud voice.

- Complete: Perfect for advanced learners and researchers needing full, unrestricted access. Unlock 1.4M+ books across hundreds of subjects, including academic and specialized titles. The Complete Plan also includes advanced features like Premium Read Aloud and Research Assistant.

We are an online textbook subscription service, where you can get access to an entire online library for less than the price of a single book per month. With over 1 million books across 1000+ topics, we’ve got you covered! Learn more here.

Look out for the read-aloud symbol on your next book to see if you can listen to it. The read-aloud tool reads text aloud for you, highlighting the text as it is being read. You can pause it, speed it up and slow it down. Learn more here.

Yes! You can use the Perlego app on both iOS or Android devices to read anytime, anywhere — even offline. Perfect for commutes or when you’re on the go.

Please note we cannot support devices running on iOS 13 and Android 7 or earlier. Learn more about using the app.

Please note we cannot support devices running on iOS 13 and Android 7 or earlier. Learn more about using the app.

Yes, you can access Guidelines for Safe Automation of Chemical Processes by in PDF and/or ePUB format, as well as other popular books in Technology & Engineering & Chemical & Biochemical Engineering. We have over one million books available in our catalogue for you to explore.

Information

Edition

21 PROCESS SAFETY AND SAFE AUTOMATION

Chemical processing is an industrial activity that involves using, storing, manufacturing, handling, or moving chemicals. Chemical processing may be accomplished in a single vessel or a group of interconnected vessels and process equipment. Process operation poses different types of risk dependent on the hazardous nature of the chemicals, the quantity of chemicals processed, and the process operating conditions.

The process equipment can be designed using inherently safer strategies to assure safe operation under foreseen process upsets, such as specifying design limits above the maximum and minimum operating parameters that exist under emergency conditions. An inherently safer process is designed to eliminate the potential for loss events with features that are inseparable from the process equipment. When process equipment is not designed to inherently withstand abnormal operation, process safety is achieved through functional safety management. Safeguards, including process control and safety systems, are specified to reduce the process risk to the risk criteria.

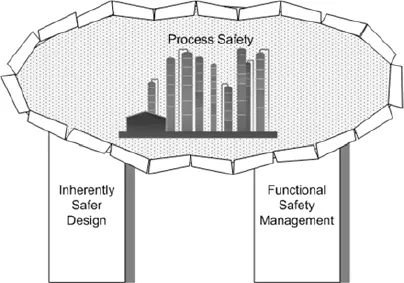

Consequently, safe operation of chemical processes is achieved through a process safety management program supported by the twin pillars of inherently safer design and functional safety management (Figure 1.1). Most process designs incorporate aspects of both inherently safer design and functional safety management. Fundamentally, it is the owner/operator’s responsibility to determine and document that the equipment is designed, maintained, inspected, tested, and operating in a safe manner, regardless of the means used to achieve this objective.

Figure 1.1. Process Safety Supported by Inherently Safer Design and Functional Safety Management

Inherently safer design involves making conscious choices to design and operate the process in a manner that avoids the hazard or minimizes the likelihood and consequence of the loss events. The word inherent means that the design feature is an essential constituent or characteristic of the process design; it becomes permanent and inseparable from the design. In contrast, functional safety management involves the addition of safeguards that act to achieve or maintain a safe state of the process when abnormal conditions occur. Safeguards can reduce the frequency and/or consequence of the loss event. Safeguards are specifically designed, maintained, inspected, tested, and operated to achieve the necessary risk reduction.

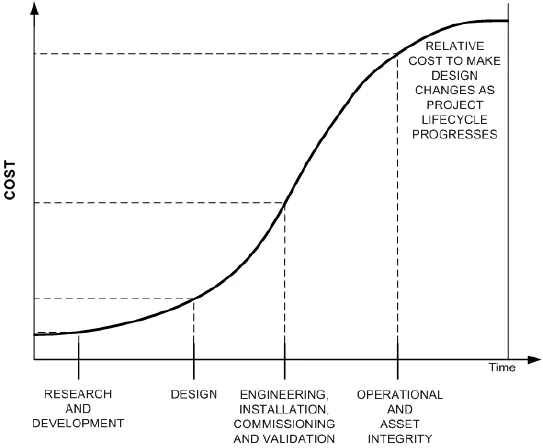

Process hazards can sometimes be reduced, or perhaps eliminated, during the design phase through inherently safer choices in process technology, equipment design, and operating parameters. When practicable, inherently safer design can minimize or eliminate the need for safeguards. Changes to the process design and operating plan should be considered as early as possible during the project life, since the relative cost of these changes typically escalates as the project progresses towards maturity (Figure 1.2). The particular means used to address risk is often influenced by the perceived effectiveness, availability, reliability, and sustainability of the protection relative to its lifecycle costs.

Figure 1.2. Relative Cost to Make Design Changes as a Function of Project Phase

Example: Designing a pipeline for maximum operating pressureConsider a scenario where the maximum discharge pressure from a pump is sufficient to overpressure a pipeline. The team evaluates 2 inherently safer design choices: (1) lower the maximum discharge pressure from the pump or (2) increase the pipeline pressure rating. Lowering the maximum pump discharge pressure requires evaluation of the needed flows and pressures for the different process operating modes to ensure that the selected pump supports the intended operating plan. A different pump specification may result in a slight capital cost change for a new installation or perhaps a maintenance expense for retrofitting an existing pump. Designing the pipeline to withstand the maximum operating pressure typically requires more capital, because higher rated piping generally is more expensive due to increased wall thickness. When the higher rated piping is installed, there is only one item to maintain – the pipe wall thickness - to assure the pipeline integrity during the facility life. If the pipeline has not been built yet, the increased pressure rating is simply a specification change with increased capital costs. If the pipeline has already been built, the change of specification would require demolition and replacement of an existing asset with associated demolition and construction costs.

The concept of designing a process to be inherently safer is covered by the Center for Chemical Process Safety (CCPS) publication, Inherently Safer Chemical Processes: A Life Cycle Approach [2009b]. A report issued by CCPS [2010a] to the Department of Homeland Security stated, “A technology can only be described as inherently safer when compared to a different technology, including a description of the hazard or set of hazards being considered, their location, and the potentially affected population.” Inherently safer design involves the use of four strategies:

- Minimize—reducing the quantity of material or energy contained in a manufacturing process or plant

- Substitute—replacing the material with a less hazardous substance; the replacement of a hazardous material or process with an alternative that reduce or eliminates the hazard

- Moderate—using materials under less hazardous conditions; using less hazardous conditions, a less hazardous form of a material, or facilities which minimize the impact of a release of hazardous material or energy

- Simplify—designing facilities which eliminate unnecessary complexity and make operating errors less likely and are forgiving of errors that are made

Inherently safer design becomes integral to the operating plan and process design basis. The design strategies typically are incorporated into customary practices, or “the way things are done,” at a site, so people come to expect certain types of design and management depending on the equipment classification. Inherently safer design involves design choices that make the process and its e...

Table of contents

- Cover

- Series Title Page

- Title Page

- Copyright

- Dedication

- List of Figures

- List of Tables

- Abbreviations

- Glossary

- Acknowledgements

- 1 Process Safety and Safe Automation

- 2 The Role of Automation In Process Safety

- 3 Automation Specification

- 4 Design and Implementation of Process Control Systems

- 5 Design and Implementation of Safety Controls, Alarms, and Interlocks (Scai)

- 6 Administrative Controls and Monitoring

- Appendix A. Control System Considerations

- Appendix B. Power, Grounding, and Shielding

- Appendix C. Communications

- Appendix D. Alarm Management

- Appendix E. Field Device Considerations

- Appendix F. Sis Equipment Selection

- Appendix G. Human Machine Interface Design

- Appendix H. Application Programming

- Appendix I. Instrument Reliability Program

- Appendix J. Acceptance Testing Guidelines

- Index

- Eula