- English

- ePUB (mobile friendly)

- Available on iOS & Android

About this book

Pipe jacking is a construction process for the no-dig laying of pipes. Successful pipe jacking demands low skin friction between the ground and the jacked pipe. This is achieved with bentonite lubrication. The bentonite slurry fed into the annular gap fulfils several purposes. It stabilises the annular gap by supporting the surrounding ground and reduces friction contact between ground and jacked pipe. The Bentonite Handbook deals comprehensibly with the relevant aspects of annular gap lubrication: starting with the ground conditions, which are of decisive importance for lubrication, through the rheological properties of the bentonite slurry to the technical components of lubrication technology and lubrication strategy. The use of standardised measuring apparatus is described as well as mixing equipment and the automatic lubrication system. Overview tables with calculations and suggested values for bentonite consumption quantities depending on the prevailing ground conditions and the pipe jacking parameters complete the recommendations.

Frequently asked questions

- Essential is ideal for learners and professionals who enjoy exploring a wide range of subjects. Access the Essential Library with 800,000+ trusted titles and best-sellers across business, personal growth, and the humanities. Includes unlimited reading time and Standard Read Aloud voice.

- Complete: Perfect for advanced learners and researchers needing full, unrestricted access. Unlock 1.4M+ books across hundreds of subjects, including academic and specialized titles. The Complete Plan also includes advanced features like Premium Read Aloud and Research Assistant.

Please note we cannot support devices running on iOS 13 and Android 7 or earlier. Learn more about using the app.

Information

1

Basics

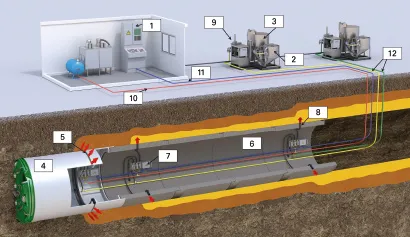

1.1 Basics and technical implementation of bentonite lubrication systems1)

- – Interval-controlled bentonite lubrication systems, in which the valves are controlled in a defined sequence.

- – Volume-controlled bentonite lubrication systems (since 2014), in which the valves are controlled according to configured demand along the route; alternatively, the valves can also be controlled in a defined sequence.

1: control unit;

2: mixing tank;

3: storage tank;

4: tunnelling machine;

5: lubrication ring;

6: advance pipe;

7: lubrication point;

8: injection fitting;

9: bentonite pump;

10: compressed air supply;

11: control cable;

12: bentonite feed.

1.1.1 Control unit

Table of contents

- Cover

- Table of Contents

- Title

- Copyright

- Dedication

- Acknowledgement

- Foreword

- List of symbols used

- 1 Basics

- 2 Bentonite and bentonite suspensions

- 3 Additives

- 4 Correct preparation of bentonite suspensions

- 5 Properties of the suspension and measurement processes

- 6 Ground and groundwater

- 7 Bentonite suspensions for annular gap lubrication

- 8 Lubrication technology

- 9 Reporting

- 10 Lists of the required injection quantities

- Literature

- End User License Agreement