Non-Destructive Evaluation of Corrosion and Corrosion-assisted Cracking

- English

- ePUB (mobile friendly)

- Available on iOS & Android

Non-Destructive Evaluation of Corrosion and Corrosion-assisted Cracking

About this book

A comprehensive text to the non-destructive evaluation of degradation of materials due to environment that takes an interdisciplinary approach

Non-Destructive Evaluation of Corrosion and Corrosion-assisted Cracking is an important resource that covers the critical interdisciplinary topic of non-destructive evaluation of degradation of materials due to environment. The authors—noted experts in the field—offer an overview of the wide-variety of approaches to non-destructive evaluation and various types of corrosion. The text is filled with instructive case studies from a range of industries including aerospace, energy, defense, and processing.

The authors review the most common non-destructive evaluation techniques that are applied in both research and industry in order to evaluate the properties and more importantly degradation of materials components or systems without causing damage. Ultrasonic, radiographic, thermographic, electromagnetic, and optical are some of the methods explored in the book. This important text:

- Offers a groundbreaking interdisciplinary approach to of non-destructive evaluation of corrosion and corrosion-assisted cracking

- Discusses techniques for non-destructive evaluation and various types of corrosion

- Includes information on the application of a variety of techniques as well as specific case studies

- Contains information targeting industries such as aerospace, energy, processing

- Presents information from leading researchers and technologists in both non-destructive evaluation and corrosion

Written for life assessment and maintenance personnel involved in quality control, failure analysis, and R&D, Non-Destructive Evaluation of Corrosion and Corrosion-assisted Cracking is an essential interdisciplinary guide to the topic.

Frequently asked questions

- Essential is ideal for learners and professionals who enjoy exploring a wide range of subjects. Access the Essential Library with 800,000+ trusted titles and best-sellers across business, personal growth, and the humanities. Includes unlimited reading time and Standard Read Aloud voice.

- Complete: Perfect for advanced learners and researchers needing full, unrestricted access. Unlock 1.4M+ books across hundreds of subjects, including academic and specialized titles. The Complete Plan also includes advanced features like Premium Read Aloud and Research Assistant.

Please note we cannot support devices running on iOS 13 and Android 7 or earlier. Learn more about using the app.

Information

1

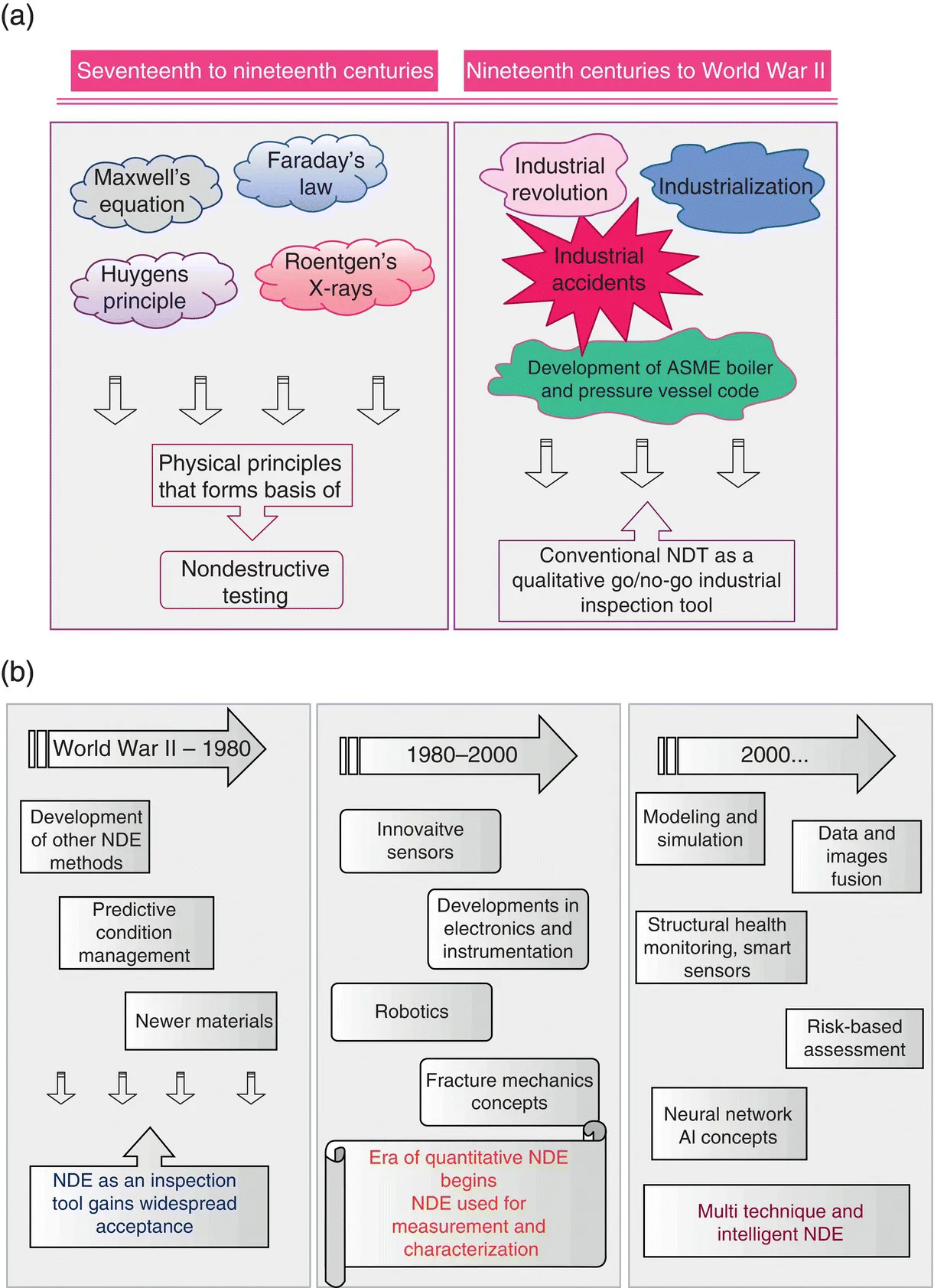

Nondestructive Testing: An Overview of Techniques and Application for Quality Evaluation

1.1 Corrosion Damage and NDE

- Ensures product quality and safety and thus fitness for purpose.

- Provides crucial inputs with respect to flaw dimensions for fracture mechanics‐based risk assessment and remnant life prediction.

- Aids in optimizing the future product design.

- Ensures reliability and customer satisfaction.

- Helps in predictive condition management by revealing incipient corrosion damage areas. Preventive measures can then be taken in timely manner, thus preventing costly shutdowns.

- Right choice of NDE techniques (single or complementary NDE techniques).

- Qualified and certified personnel.

- Calibrated sensors and equipment.

- Documented procedures with clearly defined evaluation and acceptance criteria based on standards and codes.

Table of contents

- Cover

- Table of Contents

- List of Contributors

- Foreword

- Preface

- 1 Nondestructive Testing

- 2 Corrosion

- 3 Nondestructive Evaluation of Corrosion

- 4 NDE Methods for Monitoring Corrosion and Corrosion‐assisted Cracking

- 5 Lock‐in Thermography for the Wide Area Detection of Paint Degradation and Incipient Corrosion

- 6 Electrochemical Impedance Spectroscopy for Nondestructive Evaluation of Corrosion Processes

- 7 Electrochemical Noise as Nondestructive Evaluation Technique for Understanding and Monitoring Corrosion

- 8 Evaluation of Cracking and Spallation of Oxide Scales by Acoustic Emission

- 9 Nondestructive Testing and Corrosion Monitoring

- Index

- End User License Agreement