eBook - ePub

Industrial Coal Gasification Technologies Covering Baseline and High-Ash Coal

- English

- ePUB (mobile friendly)

- Available on iOS & Android

eBook - ePub

Industrial Coal Gasification Technologies Covering Baseline and High-Ash Coal

About this book

The ongoing discussion about reaching the "peak-oil point" (maximal delivery rate with conventional methods) emphasizes a fundamental change of the frame conditions of oil-based basic products. The alternative with the largest potential is the use of coal. Coal gasification is the production of coal gas (a mixture of mainly hydrogen and carbon monoxide) from coal adding agents like steam/water and oxygen, which can be used in a number of industrial processes (e.g. hydroformulation and Fischer-Tropsch process). Many different kinds of coal do naturally occur, and due to shrinking natural resources, there has been a substantial gain of interest in poor, ash-rich coal. Beside the quality of coal, there is a number of other parameters influencing the efficiency of coal gasification, such as temperature, pressure, and reactor type.

Although several books dealing with the subject of gasification have recently been published, few are strictly focussed on coal as feedstock. This monograph provides the reader with the necessary chemical background on coal gasification. Several types of coal (baseline coal and ash-rich coal) are compared systematically, pointing out the technological efforts achieved so far to overcome this challenge. Using a new, innovative order scheme to evaluate the gasification process at a glance (the ternary diagram), the complex network of chemistry, engineering, and economic needs can be overviewed in a highly efficient way.

This book is a must-have for Chemical and Process Engineers, Engineering Students, as well as Scientists in the Chemical Industry.

Although several books dealing with the subject of gasification have recently been published, few are strictly focussed on coal as feedstock. This monograph provides the reader with the necessary chemical background on coal gasification. Several types of coal (baseline coal and ash-rich coal) are compared systematically, pointing out the technological efforts achieved so far to overcome this challenge. Using a new, innovative order scheme to evaluate the gasification process at a glance (the ternary diagram), the complex network of chemistry, engineering, and economic needs can be overviewed in a highly efficient way.

This book is a must-have for Chemical and Process Engineers, Engineering Students, as well as Scientists in the Chemical Industry.

Frequently asked questions

Yes, you can cancel anytime from the Subscription tab in your account settings on the Perlego website. Your subscription will stay active until the end of your current billing period. Learn how to cancel your subscription.

No, books cannot be downloaded as external files, such as PDFs, for use outside of Perlego. However, you can download books within the Perlego app for offline reading on mobile or tablet. Learn more here.

Perlego offers two plans: Essential and Complete

- Essential is ideal for learners and professionals who enjoy exploring a wide range of subjects. Access the Essential Library with 800,000+ trusted titles and best-sellers across business, personal growth, and the humanities. Includes unlimited reading time and Standard Read Aloud voice.

- Complete: Perfect for advanced learners and researchers needing full, unrestricted access. Unlock 1.4M+ books across hundreds of subjects, including academic and specialized titles. The Complete Plan also includes advanced features like Premium Read Aloud and Research Assistant.

We are an online textbook subscription service, where you can get access to an entire online library for less than the price of a single book per month. With over 1 million books across 1000+ topics, we’ve got you covered! Learn more here.

Look out for the read-aloud symbol on your next book to see if you can listen to it. The read-aloud tool reads text aloud for you, highlighting the text as it is being read. You can pause it, speed it up and slow it down. Learn more here.

Yes! You can use the Perlego app on both iOS or Android devices to read anytime, anywhere — even offline. Perfect for commutes or when you’re on the go.

Please note we cannot support devices running on iOS 13 and Android 7 or earlier. Learn more about using the app.

Please note we cannot support devices running on iOS 13 and Android 7 or earlier. Learn more about using the app.

Yes, you can access Industrial Coal Gasification Technologies Covering Baseline and High-Ash Coal by Martin Gräbner in PDF and/or ePUB format, as well as other popular books in Physical Sciences & Industrial & Technical Chemistry. We have over one million books available in our catalogue for you to explore.

Information

1

Introduction

A tendency toward a decrease in coal quality is reported from various parts of the world, especially in the coking coal sector. In terms of steam coals, countries such as South Africa [1], India [2], Japan [3], or even China [4] report about utilization of coal with elevated ash content. According to MacDonald et al. [5] and the ISO 11760 classification [6], coals are referred to as “high ash” or “moderately high ash” if they have an ash yield greater than 20 wt% (wf). In terms of gasification, several disadvantages can be expected as the ash content increases:

- The physical heating and cooling and melting of the ash material reduce process efficiency.

- High ash content is detrimental to carbon conversion for reasons of carbon encapsulation.

- Addition of fluxing agents to influence the ash behavior is limited.

- Increasing amounts of vaporized ash compounds could increase fouling in downstream heat exchangers.

- Coal preparation expenditures increase in terms of grinding, drying, or de-ashing.

Mineral matter reactions can additionally hamper the process, that is, oxygen consumption by substances that are not fully oxidized, such as Fe3O4 or FeS2, or CO2 release from carbonates. Special solvents might be considered to de-ash the coal [7]. However, because of recovery and regeneration problems, operational and capital costs increase while availability decreases and this option is mostly abandoned. As soon as the ash contains certain constituents (quartz and pyrite in particular), wear and abrasion in milling systems lead to extensive maintenance programs [8]. Thus, crushing should be kept at the lowest possible level.

The traditional approach to gasify such kind of feedstock is, of course, employing moving-bed systems featuring dry-ash removal, for example, Lurgi fixed-bed dry bottom (FBDB) gasification. But moving-bed technologies require a suitable grain size for bed percolation and can cope only with limited amounts of fine coal. In addition, modern mining technologies produce increasing quantities of fine coal and the high-ash content prevents acceptable agglomeration properties, for example, for briquetting. Consequently, vast amounts of high-ash coal fines are left over from moving-bed processes or other coal washing and beneficiation processes. These cannot be gasified efficiently using today's standard technologies [9].

The task of the present book is to investigate the capability of existing technologies and the potential of new concepts for processing high-ash coal. A study is carried out using a high-ash coal from South Africa – especially fines for pulverized coal application – compared to a baseline standard coal, which is American Pittsburgh No. 8 bituminous coal. To compare the different approaches, thermodynamic modeling and exergy analysis will be applied. The evaluation of the results should lead to the identification of the most promising concept, which is intended to be investigated in a case study.

References

- 1. Everson, R.C., Neomagus, H.W., Kaitano, R., van Falcon, R., Alphen, C., and du Cann, V.M. (2008) Properties of high ash char particles derived from inertinite-rich coal: 1. Chemical, structural and petrographic characteristics. Fuel, 87 (13–14), 3082–3090.

- 2. Iyengar, R. and Haque, R. (1991) Gasification of high-ash Indian coals for power generation. Fuel Processing Technology, 27 (3), 247–262.

- 3. Kurose, R., Ikeda, M., and Makino, H. (2001) Combustion characteristics of high ash coal in a pulverized coal combustion. Fuel, 80 (10), 1447–1455.

- 4. Liu, G., Zheng, L., Gao, L., Zhang, H., and Peng, Z. (2005) The characterization of coal quality from the jining coalfield. Energy, 30 (10), 1903–1914.

- 5. MacDonald, M., Chadwick, M., and Aslanian, G. (1996) The Environmental Management of Low-Grade Fuels, Earthscan Publications Limited, London.

- 6. ISO (2005) 11760, Classification of Coals, International Standards Organization, Geneva, Switzerland.

- 7. Okuyama, N., Komatsu, N., Shigehisa, T., Kaneko, T., and Tsuruya, S. (2004) Hyper-coal process to produce the ash-free coal. Fuel Processing Technology, 85 (8–10), 947–967.

- 8. Wells, J.J., Wigley, F., Foster, D.J., Gibb, W.H., and Williamson, J. (2004) The relationship between excluded mineral matter and the abrasion index of a coal. Fuel, 83 (3), 359–364.

- 9. Govender, A. and van Dyk, J.C. (2003) Effect of wet screening on particle size distribution and coal properties. Fuel, 82 (18), 2231–2237.

2

Coal Gasification in a Global Context

2.1 Applications of Coal Gasification

Any carbonaceous feedstock, may it be gaseous, liquid, or solid, can undergo a partial oxidation. As soon as oxidation heat is released, high-temperature conditions evolve permitting other gases, such as steam or carbon dioxide, to react with the carbonaceous feedstock. The result is the autothermal breakdown of the feedstock to the smallest stable chemical units that can still carry some energy. These units are the gases hydrogen, carbon monoxide, and sometimes methane. The breakdown process is called gasification and the gaseous product is called synthesis gas or syngas. Although the term “syngas” traces to gases produced for the sole purpose of downstream syntheses, it established itself as a term for any product gas from gasification independent of application. (Further details and thermodynamic definitions are provided in Chapter 4.)

The composition of the syngas varies and is essentially linked to the quality of the feedstock and the conditions of the gasification process, such as temperature and pressure. Furthermore, each kind of gasification process is specialized in a certain feedstock spectrum. Finally, the usage of the gas produced specifies varying parameters, such as heating value, pressure level, H2/CO ratio, and maximum concentration of sulfur compounds.

Hence, the closing of the gap between carbonaceous feedstock and a selected final product, which is intended to be sold from the plant, is a technical and economical optimization problem with usually more than one solution. In this framework, the different gasification technologies are the basis for competition on the market.

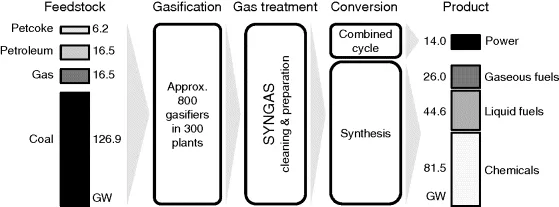

The conversion chain of gasification plants as shown in Figure 2.1 can be generalized in three steps moving from feedstock to product: gasification, gas treatment, and conversion to product.

Figure 2.1 Gasification conversion chain from feedstock to product. (The numbers in gigawatt (GW) refer to global syngas capacity of currently operating units and plants under construction [1].)

In Figure 2.1, the sum of installed and under-construction capacity in GW syngas is distinguished for feedstock and products. On the feedstock side, it can be seen that coal with 126.9 GW represents more than ...

Table of contents

- Cover

- Related Titles

- Title Page

- Copyright

- Dedication

- Preface

- Chapter 1: Introduction

- Chapter 2: Coal Gasification in a Global Context

- Chapter 3: Coal Characterization for Gasification

- Chapter 4: Fundamentals

- Chapter 5: Coal Gasification Modeling

- Chapter 6: Coal Gasification Technology Survey

- Chapter 7: Thermodynamic Process Assessment

- Chapter 8: Exergetic Process Assessment

- Chapter 9: Concept Study: The Internal Circulation Gasifier

- Chapter 10: Trends of Gasification Development

- Index

- End User License Agreement