- English

- ePUB (mobile friendly)

- Available on iOS & Android

Progress in Adhesion and Adhesives, Volume 3

About this book

A solid collection of interdisciplinary review articles on the latest developments in adhesion science and adhesives technology

With the ever-increasing amount of research being published, it is a Herculean task to be fully conversant with the latest research developments in any field, and the arena of adhesion and adhesives is no exception. Thus, topical review articles provide an alternate and very efficient way to stay abreast of the state-of-the-art in many subjects representing the field of adhesion science and adhesives.

Based on the success of the preceding volumes in this series "Progress in Adhesion and Adhesives"), the present volume comprises 12 review articles published in Volume 5 (2017) of Reviews of Adhesion and Adhesives.

The subject of these 12 reviews fall into the following general areas:

1. Nanoparticles in reinforced polymeric composites.

2. Wettability behavior and its modification, including superhydrophobic surfaces.

3. Ways to promote adhesion, including rubber adhesion.

4. Adhesives and adhesive joints

5. Dental adhesion.

The topics covered include: Nanoparticles as interphase modifiers in fiber reinforced polymeric composites; fabrication of micro/nano patterns on polymeric substrates to control wettability behavior; plasma processing of aluminum alloys to promote adhesion; UV-curing of adhesives; functionally graded adhesively bonded joints; adhesion between unvulgarized elastomers; electrowetting for digital microfluidics; control of biofilm at the tooth-restoration bonding interface; easy-to-clean superhydrophobic coatings; cyanoacrylates; promotion of resin-dentin bond longevity in adhesive dentistry; and effects of nanoparticles on nanocomposites Mode I and Mode II fractures.

Frequently asked questions

- Essential is ideal for learners and professionals who enjoy exploring a wide range of subjects. Access the Essential Library with 800,000+ trusted titles and best-sellers across business, personal growth, and the humanities. Includes unlimited reading time and Standard Read Aloud voice.

- Complete: Perfect for advanced learners and researchers needing full, unrestricted access. Unlock 1.4M+ books across hundreds of subjects, including academic and specialized titles. The Complete Plan also includes advanced features like Premium Read Aloud and Research Assistant.

Please note we cannot support devices running on iOS 13 and Android 7 or earlier. Learn more about using the app.

Information

Chapter 1

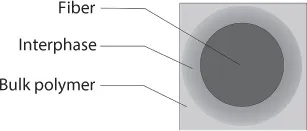

Nanoparticles as Interphase Modifiers in Fiber Reinforced Polymeric Composites: A Critical Review

Abstract

1.1 Introduction

1.2 Grown Interphases from Fiber Surfaces

1.2.1 Introduction

Table of contents

- Cover

- Title page

- Copyright page

- Preface

- Chapter 1: Nanoparticles as Interphase Modifiers in Fiber Reinforced Polymeric Composites: A Critical Review

- Chapter 2: Fabrication of Micro/Nano Patterns on Polymeric Substrates Using Laser Ablation Methods to Control Wettability Behaviour: A Critical Review

- Chapter 3: Plasma Processing of Aluminum Alloys to Promote Adhesion: A Critical Review

- Chapter 4: UV-Curing of Adhesives: A Critical Review

- Chapter 5: Stress and Failure Analyses of Functionally Graded Adhesively Bonded Joints of Laminated FRP Composite Plates and Tubes: A Critical Review

- Chapter 6: Adhesion Between Unvulcanized Elastomers: A Critical Review

- Chapter 7: Dielectrowetting for Digital Microfluidics: Principle and Application. A Critical Review

- Chapter 8: Control of Biofilm at the Tooth-Restoration Bonding Interface: A Question for Antibacterial Monomers? A Critical Review

- Chapter 9: Easy-to-Clean Superhydrophobic Coatings Based on Sol-Gel Technology: A Critical Review

- Chapter 10: Cyanoacrylates: Towards High Temperature Resistant Instant Adhesives. A Critical Review

- Chapter 11: Strategies to Inactivate the Endogenous Dentin Proteases to Promote Resin-Dentin Bond Longevity in Adhesive Dentistry: A Critical Review

- Chapter 12: Effects of Nanoparticles on Nanocomposites Mode I and II Fracture: A Critical Review

- End User License Agreement