eBook - ePub

Handbook of Software Solutions for ICME

- English

- ePUB (mobile friendly)

- Available on iOS & Android

eBook - ePub

Handbook of Software Solutions for ICME

About this book

As one of the results of an ambitious project, this handbook provides a well-structured directory

of globally available software tools in the area of Integrated Computational Materials

Engineering (ICME).

The compilation covers models, software tools, and numerical methods allowing describing

electronic, atomistic, and mesoscopic phenomena, which in their combination determine the

microstructure and the properties of materials. It reaches out to simulations of component

manufacture comprising primary shaping, forming, joining, coating, heat treatment, and

machining processes. Models and tools addressing the in-service behavior like fatigue, corrosion,

and eventually recycling complete the compilation.

An introductory overview is provided for each of these different modelling areas highlighting the

relevant phenomena and also discussing the current state for the different simulation approaches.

A must-have for researchers, application engineers, and simulation software providers seeking

a holistic overview about the current state of the art in a huge variety of modelling topics.

This handbook equally serves as a reference manual for academic and commercial software developers

and providers, for industrial users of simulation software, and for decision makers seeking

to optimize their production by simulations. In view of its sound introductions into the different

fields of materials physics, materials chemistry, materials engineering and materials processing

it also serves as a tutorial for students in the emerging discipline of ICME, which requires a broad

view on things and at least a basic education in adjacent fields.

of globally available software tools in the area of Integrated Computational Materials

Engineering (ICME).

The compilation covers models, software tools, and numerical methods allowing describing

electronic, atomistic, and mesoscopic phenomena, which in their combination determine the

microstructure and the properties of materials. It reaches out to simulations of component

manufacture comprising primary shaping, forming, joining, coating, heat treatment, and

machining processes. Models and tools addressing the in-service behavior like fatigue, corrosion,

and eventually recycling complete the compilation.

An introductory overview is provided for each of these different modelling areas highlighting the

relevant phenomena and also discussing the current state for the different simulation approaches.

A must-have for researchers, application engineers, and simulation software providers seeking

a holistic overview about the current state of the art in a huge variety of modelling topics.

This handbook equally serves as a reference manual for academic and commercial software developers

and providers, for industrial users of simulation software, and for decision makers seeking

to optimize their production by simulations. In view of its sound introductions into the different

fields of materials physics, materials chemistry, materials engineering and materials processing

it also serves as a tutorial for students in the emerging discipline of ICME, which requires a broad

view on things and at least a basic education in adjacent fields.

Frequently asked questions

Yes, you can cancel anytime from the Subscription tab in your account settings on the Perlego website. Your subscription will stay active until the end of your current billing period. Learn how to cancel your subscription.

No, books cannot be downloaded as external files, such as PDFs, for use outside of Perlego. However, you can download books within the Perlego app for offline reading on mobile or tablet. Learn more here.

Perlego offers two plans: Essential and Complete

- Essential is ideal for learners and professionals who enjoy exploring a wide range of subjects. Access the Essential Library with 800,000+ trusted titles and best-sellers across business, personal growth, and the humanities. Includes unlimited reading time and Standard Read Aloud voice.

- Complete: Perfect for advanced learners and researchers needing full, unrestricted access. Unlock 1.4M+ books across hundreds of subjects, including academic and specialized titles. The Complete Plan also includes advanced features like Premium Read Aloud and Research Assistant.

We are an online textbook subscription service, where you can get access to an entire online library for less than the price of a single book per month. With over 1 million books across 1000+ topics, we’ve got you covered! Learn more here.

Look out for the read-aloud symbol on your next book to see if you can listen to it. The read-aloud tool reads text aloud for you, highlighting the text as it is being read. You can pause it, speed it up and slow it down. Learn more here.

Yes! You can use the Perlego app on both iOS or Android devices to read anytime, anywhere — even offline. Perfect for commutes or when you’re on the go.

Please note we cannot support devices running on iOS 13 and Android 7 or earlier. Learn more about using the app.

Please note we cannot support devices running on iOS 13 and Android 7 or earlier. Learn more about using the app.

Yes, you can access Handbook of Software Solutions for ICME by Georg J. Schmitz, Ulrich Prahl, Georg J. Schmitz,Ulrich Prahl in PDF and/or ePUB format, as well as other popular books in Technology & Engineering & Materials Science. We have over one million books available in our catalogue for you to explore.

Information

Chapter 1

Introduction

Georg J. Schmitz and Ulrich Prahl

1.1 Motivation

Integrated Computational Materials Engineering (ICME) – by its name and its nature – draws on the combination and the simultaneous or consecutive use of a variety of software and modeling tools. This simple phrase immediately raises a number of further questions:

- How to combine tools?

- How to select suitable tools?

- How to decide on a specific tool?

- And many more …

Eventually, before answering these questions, some even more direct issues arise:

- Which tools are available at all?

- How to become aware about suitable tools?

Thus, there is obviously a need for something like the “yellow pages of software solutions for ICME” or a similar “one-stop shop” like institution. Such kind of yellow pages listing – even if being very comprehensive – would be quite boring to read (and also to write…) and probably would even be outdated after a short time in view of new codes emerging and old codes being discontinued.

The ICMEg project partners [1] therefore decided to extend the scope of this book beyond the “yellow pages” and to include also a general introduction and overviews to the different fields, models, and software tools. The book content thus eventually evolved into an “overview” of overviews. All contributions are as generic as possible and references are mainly limited to “further reading” and refer to textbooks and tutorials for the different fields and review articles. The book also provides an “overview” of tutorials, reviews, and textbooks for the different fields.

Major scope, however, is to “name” phenomena, models, descriptors, and other terms and to arrange them in an overall context structure. Looking up the details behind the different “names” is left to the reader and nowadays can often best be achieved by drawing on the Internet.

In summary, the ultimate motivation for the authors to write this book is that it could become a standard tutorial for future ICME engineers, which by nature of ICME need to have a holistic education, a general background, and a “bird's eye view” on things.

The motivation for this book is making the first steps toward providing a thematically structured directory of the huge and heterogeneous variety of state-of-the-art models (Figure 1.1). It is thus also particularly suited for young scientists and engineers seeking an overview of modern simulation tools in the area of Computational Materials Science and ICME.

Figure 1.1 A large variety of simulation tools is available around the globe. Not all codes in general have their own websites and logos. There is an even bigger number of particularly academic tools that are hidden and waiting to be exploited.

1.2 What is ICME?

“Integrated computational materials engineering (ICME) as an emerging discipline aiming to integrate computational materials science tools into a holistic system will accelerate materials development, transform the engineering design optimization process, and unify design and manufacturing” [2].

Looking at the names, a definition of ICME has been attempted in a previous book [3] based on the analysis of the ingredients I, C, M, and E. An ambiguity has been identified with respect to the term “E” – engineering – which is applied to a product/component in Computational Engineering/Integrated Computational Engineering (CE/ICE) and to a specific material in Computational Materials/Computational Materials Engineering (CM/CME). This ambiguity can be resolved by putting the focus of ICME on:

Engineering the properties of a component as a function of the local properties of the material inside the component and along its entire production and service life cycle

“I” in this context especially means integrating along the process chain (time, history), integrating across the scales (space, structures), integrating several models/tools, and integrating real and virtual worlds. “E” refers to engineering of technical alloy systems, engineering under industrial boundary conditions, and engineering of materials in components during manufacture and under operational load.

Technically, ICME is an approach for solving advanced engineering problems related to the design of new materials, processes, and products by combining individual materials and process models. Is ICME just a synonym for the coupling/linking of simulation tools by data exchange? From a systems point of view, the coupling of individual models and/or software codes across length scales and along material processing chains leads to highly complex metamodels.

ICME thus is more than just linking/coupling tools. The global optimum of a process chain might – and actually will – differ from a chain of individually optimized process steps (Figure 1.2).

Figure 1.2 Example for a global optimum. Slightly suboptimal casting cycles with samples remaining at higher temperature for some more time may allow for shorter heat treatment times and thus result in an overall shorter production cycle.

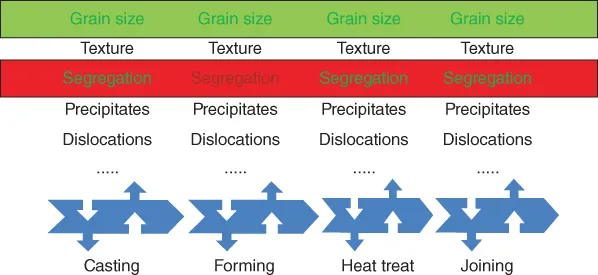

ICME is also not only about exchange of some data between different simulation tools but further requires information contingency in view of subsequent processes downstream the value chain (Figure 1.3).

Figure 1.3 The importance of information contingency for the example of a process chain. While, for example, the grain size is simulated in all tools, the segregation of alloy elements is not modeled in the “forming” step. Segregation however becomes important again in subsequent processes.

ICME currently is already known to combine, to address, and to exploit “processing–microstructure” relationships and “microstructure–property” relationships. An emerging area is the “microstructure–processing” relationship, which investigates how processing is affected by the initial microstructure or how the microstructure affects the robustness of a process – in other words, how the history of a component affects its response to processing and how it defines its properties for operation.

In summary, ICME is an emerging iscipline spanning various disciplines from materials technology, mechanical engineering, chemical and physical science, information technology, and numerical and mathematical science, for which a generic structural framework has to be elaborated, established, and maintained.

1.3 Industrial Needs for ICME

When discussing the industrial needs for ICME, two perspectives have to be differentiated. On the one hand, there are the commercial software providers trying to provide their software solutions to as many customers as possible. On the other hand, any industrial user of software tools is interested in exploiting software solutions to design new materials and production processes for components with tailored performance. The interests and needs of these two communities have to be discussed independently.

The interests of commercial software providers in ICME essentially relate to providing software solutions, to continuously developing new functionalities, to providing data along with their models, to making models faster and/or more robust, to making reliable/predictive models, and eventually to earning money by selling their software solutions and/or their simulation-based consulting competence.

Commercial software industry needs to identify, meet, and anticipate the needs of industrial users of their models and codes. This especially includes anticipating the potential needs not even yet being identified by these users themselves. The situation somehow corresponds to a fire brigade, which in general is not needed but anybody is happy to have it in case of a fire. The better the software provider meets the industrial user's needs for specific application tasks, the higher the user's motivation will be to further use (and thus to pay for…) the provider's software solution.

Even before any type of simulation was available, people were already able to construct airplanes. Nowadays – using simulations – they can do it faster, cheaper, better, and also with less ecologic impact. Currently, however, materials data entering respective finite element method (FEM) simulations are still often estimates based on similar materials, being isotropic and often revealing no temperature dependency. Large safety margins thus have still to be considered making the airplane heavier than needed. Better understanding and knowledge of materials and their processing will open pathways to new designs and even lighter airplanes.

From the application point of view, the industrial user of ICME is interested in solutions to his actual, real problems in ongoing production processes. He aims at optimizing current production sequences and the value of his products or at obtaining an improved understanding and control of materials and processes along the production chain. He aims at improving his products and processes in terms of cost and time and to increase the planning quality toward predictability of process chains to decrease waste and recycling material. Additionally he will develop new materials, new processes, and new products and will exploit emerging new options and applications. Eventually, simulation shall support a faster time to marke...

Table of contents

- Cover

- Title Page

- Copyright

- Table of Contents

- List of Contributors

- Preface

- Chapter 1: Introduction

- Chapter 2: Modeling at the Process and Component Scales

- Chapter 3: Microstructure Modeling

- Chapter 4: Thermodynamics

- Chapter 5: Discrete Models: Down to Atoms and Electrons

- Chapter 6: Effective Properties

- Chapter 7: Numerical Methods

- Chapter 8: Platforms for ICME

- Chapter 9: Future Directions

- Index

- End User License Agreement