eBook - ePub

Introduction to Maintenance Engineering

Modelling, Optimization and Management

- English

- ePUB (mobile friendly)

- Available on iOS & Android

eBook - ePub

Introduction to Maintenance Engineering

Modelling, Optimization and Management

About this book

This introductory textbook links theory with practice using real illustrative cases involving products, plants and infrastructures and exposes the student to the evolutionary trends in maintenance.

- Provides an interdisciplinary approach which links, engineering, science, technology, mathematical modelling, data collection and analysis, economics and management

- Blends theory with practice illustrated through examples relating to products, plants and infrastructures

- Focuses on concepts, tools and techniques

- Identifies the special management requirements of various engineered objects (products, plants, and infrastructures)

Tools to learn more effectively

Saving Books

Keyword Search

Annotating Text

Listen to it instead

Information

1

An Overview

Learning Outcomes

After reading this chapter, you should be able to:

- Define maintenance and explain its importance from a strategic business perspective;

- List the three main aspects of maintenance;

- Provide a classification of engineered objects;

- Describe reliability and non-reliability performance measures of engineered objects;

- Describe the factors that affect performance degradation;

- Recognize the consequences of poor maintenance;

- Describe the main categories of maintenance costs;

- Explain that there is a trade-off between preventive maintenance effort and maintenance costs;

- Explain that there are maintenance decision-making problems at the strategic, tactical, and operational levels;

- Describe the evolution of maintenance over time and the new trends;

- Understand the structure of the book.

1.1 Introduction

Modern societies use a range of engineered objects for many different purposes. The objects are designed and built for specific functions. These include a variety of products (used by households, businesses, and government in their daily operations), plants, and facilities (used by businesses to deliver goods and services) and a range of infrastructures (networks such as rail, road, water, gas, electricity; dams, buildings, etc.) to ensure the smooth functioning of a society.

Every engineered object is unreliable in the sense that it degrades with age and/or usage and ultimately fails. A dictionary definition of failure is “falling short in something expected, attempted, desired, or in some way deficient or lacking.” From an engineering point of view, an engineered object is said to have failed when it is no longer able to carry out its intended function for which it was designed and built. Failures occur in an uncertain manner and are influenced by several factors such as design, manufacture (or construction), maintenance, and operation. In addition, the human factor is also important in this context.

The consequence of a product failure may vary from mere inconvenience (for example, a dishwasher failure) to something serious (for example, an automobile brake failure leading to economic and possibly human loss). The failure of an industrial plant or commercial facility may have major economic consequences for a business as it affects the delivery of goods and services (outputs of the business) and the revenue generation. The daily loss in revenue as a result of the product being out of action due to failure may be very high. Rough estimates (circa 2000) for the revenue lost due to engineered objects being out of action are as follows:

- Large aircraft (A340 or Boeing 747) ~ $500 000/day;

- Dragline (used in open cut mining) ~ $1 million/day;

- A large manufacturer (for example, Toyota) ~ $1–2 millions/hour.

Definition 1.1

Maintenance is the combination of all technical, administrative, and managerial actions during the life cycle of an item intended to retain it in, or restore it to, a state in which it may perform the required function (CEN, 2001).

In a sense, maintenance may be viewed as actions to compensate for the unreliability of an engineered object. Building in reliability is costly and is constrained by technical limits and economic considerations. However, not having adequate reliability is costlier due to the consequence of failures. Thus, maintenance becomes an important issue in this context. Table 1.1 shows the maintenance costs (as a fraction of the operating costs) in different industry sectors, as reported in Campbell (1995).

Table 1.1 Maintenance as a percentage of operating cost.

| Industry sector | Maintenance cost (%) |

| Mining (highly mechanized) | 20–50 |

| Primary metals | 15–20 |

| Electric utilities | 5–15 |

| Manufacturing processing | 3–15 |

| Fabrication/assembly | 3–5 |

There are several aspects to maintenance and they may be grouped broadly into the following three categories:

- Technical (engineering, science, technology, etc.);

- Commercial (economics, legal, marketing, etc.);

- Management (from several different perspectives – manufacturer, customer and maintenance service provider when maintenance is outsourced).

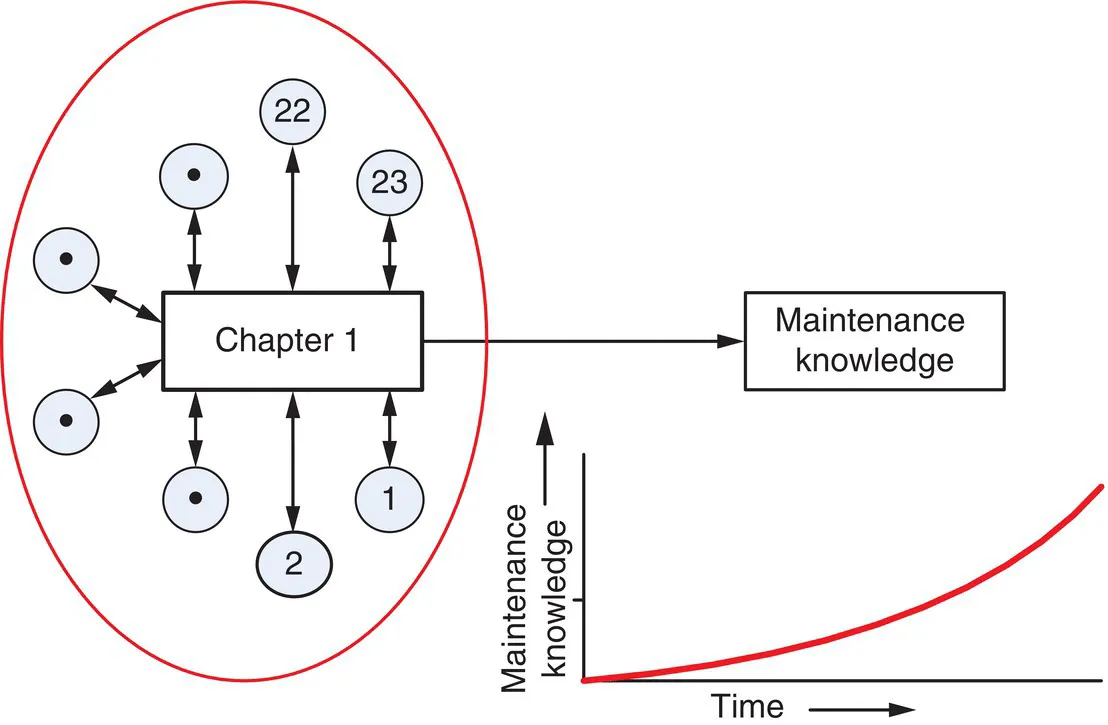

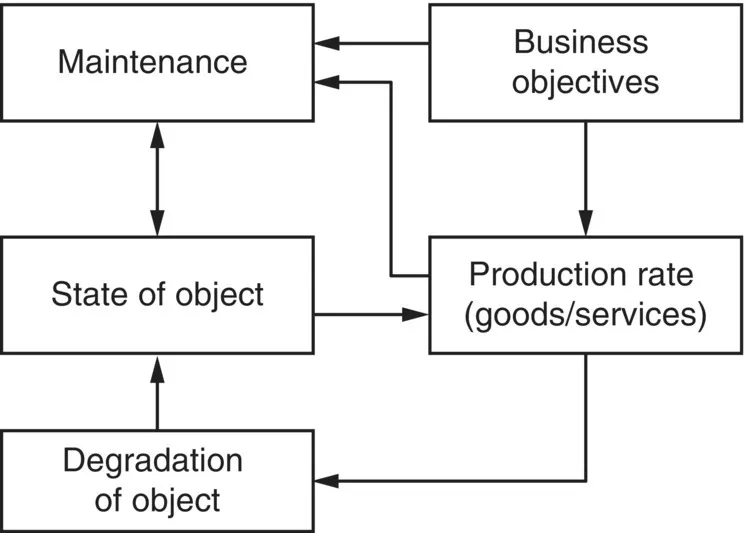

This implies that maintenance decisions need to be made in a framework that takes into account these issues from an overall business perspective. Figure 1.1 shows the link between maintenance (strategic and operational) and production from a business perspective.1

Figure 1.1 Maintenan...

Table of contents

- Cover

- Title Page

- Table of Contents

- Preface

- Acknowledgments

- Abbreviations

- 1 An Overview

- Part A: Maintenance Engineering and Technology

- Part B: Reliability and Maintenance Modeling

- Part C: Maintenance Decision Models and Optimization

- Part D: Maintenance Management

- Part E: Case Studies

- Part F: Appendices

- Index

- End User License Agreement

Frequently asked questions

Yes, you can cancel anytime from the Subscription tab in your account settings on the Perlego website. Your subscription will stay active until the end of your current billing period. Learn how to cancel your subscription

No, books cannot be downloaded as external files, such as PDFs, for use outside of Perlego. However, you can download books within the Perlego app for offline reading on mobile or tablet. Learn how to download books offline

Perlego offers two plans: Essential and Complete

- Essential is ideal for learners and professionals who enjoy exploring a wide range of subjects. Access the Essential Library with 800,000+ trusted titles and best-sellers across business, personal growth, and the humanities. Includes unlimited reading time and Standard Read Aloud voice.

- Complete: Perfect for advanced learners and researchers needing full, unrestricted access. Unlock 1.4M+ books across hundreds of subjects, including academic and specialized titles. The Complete Plan also includes advanced features like Premium Read Aloud and Research Assistant.

We are an online textbook subscription service, where you can get access to an entire online library for less than the price of a single book per month. With over 1 million books across 990+ topics, we’ve got you covered! Learn about our mission

Look out for the read-aloud symbol on your next book to see if you can listen to it. The read-aloud tool reads text aloud for you, highlighting the text as it is being read. You can pause it, speed it up and slow it down. Learn more about Read Aloud

Yes! You can use the Perlego app on both iOS and Android devices to read anytime, anywhere — even offline. Perfect for commutes or when you’re on the go.

Please note we cannot support devices running on iOS 13 and Android 7 or earlier. Learn more about using the app

Please note we cannot support devices running on iOS 13 and Android 7 or earlier. Learn more about using the app

Yes, you can access Introduction to Maintenance Engineering by Mohamed Ben-Daya,Uday Kumar,D. N. Prabhakar Murthy in PDF and/or ePUB format, as well as other popular books in Technology & Engineering & Mechanical Engineering. We have over one million books available in our catalogue for you to explore.