Next Generation HALT and HASS

Robust Design of Electronics and Systems

- English

- ePUB (mobile friendly)

- Available on iOS & Android

Next Generation HALT and HASS

Robust Design of Electronics and Systems

About this book

A NEW APPROACH TO DISCOVERING AND CORRECTING SYSTEMS RELIABILITY RISKS

Next Generation HALT and HASS presents a major paradigm shift from reliability prediction-based methods to discovery of electronic systems reliability risks. This is achieved by integrating highly accelerated life test (HALT) and highly accelerated stress screen (HASS) into a physics of failure based robust product and process development methodology. The new methodologies challenge misleading and sometimes costly misapplication of probabilistic failure prediction methods (FPM) and provide a new deterministic map for reliability development. The authors clearly explain the new approach with a logical progression of problem statement and solutions.

The book helps engineers employ HALT and HASS by demonstrating why the misleading assumptions used for FPM are invalid. Next, the application of HALT and HASS empirical discovery methods to quickly find unreliable elements in electronics systems gives readers practical insight into the techniques.

The physics of HALT and HASS methodologies are highlighted, illustrating how they uncover and isolate software failures due to hardware–software interactions in digital systems. The use of empirical operational stress limits for the development of future tools and reliability discriminators is described.

Key features:

- Provides a clear basis for moving from statistical reliability prediction models to practical methods of insuring and improving reliability.

- Challenges existing failure prediction methodologies by highlighting their limitations using real field data.

- Explains a practical approach to why and how HALT and HASS are applied to electronics and electromechanical systems.

- Presents opportunities to develop reliability test discriminators for prognostics using empirical stress limits.

- Guides engineers and managers on the benefits of the deterministic and more efficient methods of HALT and HASS.

- Integrates the empirical limit discovery methods of HALT and HASS into a physics of failure based robust product and process development process.

Frequently asked questions

- Essential is ideal for learners and professionals who enjoy exploring a wide range of subjects. Access the Essential Library with 800,000+ trusted titles and best-sellers across business, personal growth, and the humanities. Includes unlimited reading time and Standard Read Aloud voice.

- Complete: Perfect for advanced learners and researchers needing full, unrestricted access. Unlock 1.4M+ books across hundreds of subjects, including academic and specialized titles. The Complete Plan also includes advanced features like Premium Read Aloud and Research Assistant.

Please note we cannot support devices running on iOS 13 and Android 7 or earlier. Learn more about using the app.

Information

1

Basis and Limitations of Typical Current Reliability Methods and Metrics

Reliability cannot be achieved by adhering to detailed specifications. Reliability cannot be achieved by formula or by analysis. Some of these may help to some extent, but there is only one road to reliability. Build it, test it and fix the things that go wrong. Repeat the process until the desired reliability is achieved. It is a feedback process and there is no other way.David Packard, 1972

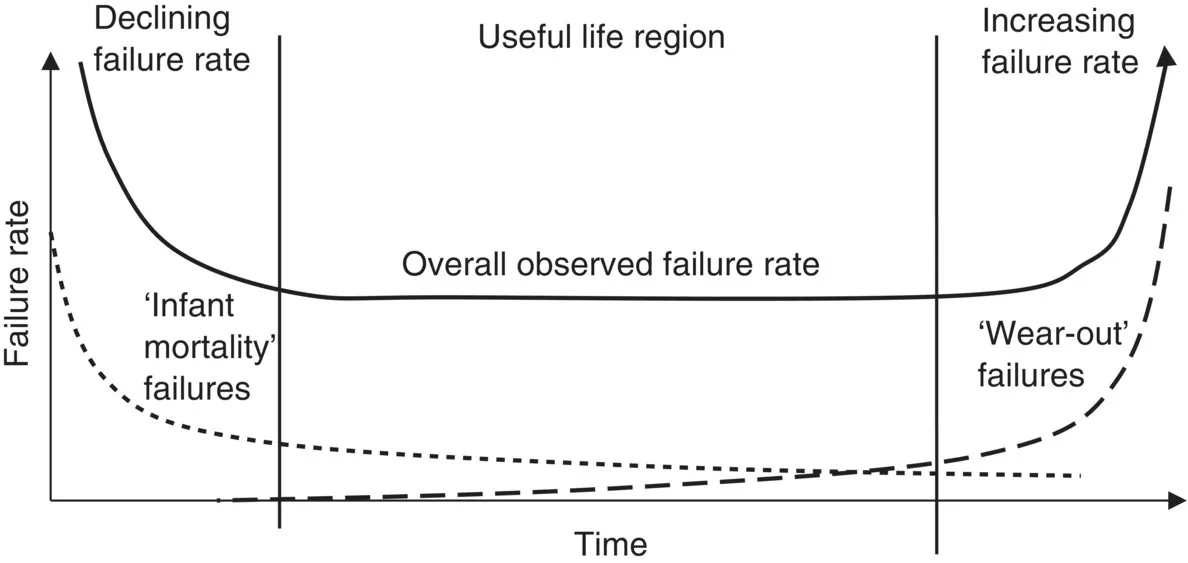

1.1 The Life Cycle Bathtub Curve

Table of contents

- Cover

- Title Page

- Table of Contents

- Series Editor’s Foreword

- Preface

- List of Acronyms

- Introduction

- 1 Basis and Limitations of Typical Current Reliability Methods and Metrics

- 2 The Need for Reliability Assurance Reference Metrics to Change

- 3 Challenges to Advancing Electronics Reliability Engineering

- 4 A New Deterministic Reliability Development Paradigm

- 5 Common Understanding of HALT Approach is Critical for Success

- 6 The Fundamentals of HALT

- 7 Highly Accelerated Stress Screening (HASS) and Audits (HASA)

- 8 HALT Benefits for Software/Firmware Performance and Reliability

- 9 Design Confirmation Test

- 10 Failure Analysis and Corrective Action

- 11 Additional Applications of HALT Methods

- Appendix: HALT and Reliability Case Histories

- Index

- Wiley Series in Quality and Reliability Engineering

- End User License Agreement