eBook - ePub

Design of Fastenings for Use in Concrete

The CEN/TS 1992-4 Provisions

- English

- ePUB (mobile friendly)

- Available on iOS & Android

eBook - ePub

Design of Fastenings for Use in Concrete

The CEN/TS 1992-4 Provisions

About this book

The European pre-standard CEN/TS 1992-4 for the design of fastenings by means of headed studs, anchor channels as well as post-installed mechanical and chemical anchors is ready for use. The background and interpretation of the provisions related to the determination of actions and resistances based on limit state design, durability, fire resistance, fatigue and earthquake actions as required by CEN/TS 1992 are described in detail.

Selected chapters from the German concrete yearbook are now being published in the new English "Beton-Kalender Series" for the benefit of an international audience.

Since it was founded in 1906, the Ernst & Sohn "Beton-Kalender" has been supporting developments in reinforced and prestressed concrete. The aim was to publish a yearbook to reflect progress in "ferro-concrete" structures until - as the book's first editor, Fritz von Emperger (1862-1942), expressed it - the "tempestuous development" in this form of construction came to an end. However, the "Beton-Kalender" quickly became the chosen work of reference for civil and structural engineers, and apart from the years 1945-1950 has been published annually ever since.

Selected chapters from the German concrete yearbook are now being published in the new English "Beton-Kalender Series" for the benefit of an international audience.

Since it was founded in 1906, the Ernst & Sohn "Beton-Kalender" has been supporting developments in reinforced and prestressed concrete. The aim was to publish a yearbook to reflect progress in "ferro-concrete" structures until - as the book's first editor, Fritz von Emperger (1862-1942), expressed it - the "tempestuous development" in this form of construction came to an end. However, the "Beton-Kalender" quickly became the chosen work of reference for civil and structural engineers, and apart from the years 1945-1950 has been published annually ever since.

Frequently asked questions

Yes, you can cancel anytime from the Subscription tab in your account settings on the Perlego website. Your subscription will stay active until the end of your current billing period. Learn how to cancel your subscription.

No, books cannot be downloaded as external files, such as PDFs, for use outside of Perlego. However, you can download books within the Perlego app for offline reading on mobile or tablet. Learn more here.

Perlego offers two plans: Essential and Complete

- Essential is ideal for learners and professionals who enjoy exploring a wide range of subjects. Access the Essential Library with 800,000+ trusted titles and best-sellers across business, personal growth, and the humanities. Includes unlimited reading time and Standard Read Aloud voice.

- Complete: Perfect for advanced learners and researchers needing full, unrestricted access. Unlock 1.4M+ books across hundreds of subjects, including academic and specialized titles. The Complete Plan also includes advanced features like Premium Read Aloud and Research Assistant.

We are an online textbook subscription service, where you can get access to an entire online library for less than the price of a single book per month. With over 1 million books across 1000+ topics, we’ve got you covered! Learn more here.

Look out for the read-aloud symbol on your next book to see if you can listen to it. The read-aloud tool reads text aloud for you, highlighting the text as it is being read. You can pause it, speed it up and slow it down. Learn more here.

Yes! You can use the Perlego app on both iOS or Android devices to read anytime, anywhere — even offline. Perfect for commutes or when you’re on the go.

Please note we cannot support devices running on iOS 13 and Android 7 or earlier. Learn more about using the app.

Please note we cannot support devices running on iOS 13 and Android 7 or earlier. Learn more about using the app.

Yes, you can access Design of Fastenings for Use in Concrete by Rainer Mallée,Rolf Eligehausen, Konrad Bergmeister,Frank Fingerloos,Johann-Dietrich Wörner,Johann-Dietrich Worner, Werner Fuchs in PDF and/or ePUB format, as well as other popular books in Technology & Engineering & Civil Engineering. We have over one million books available in our catalogue for you to explore.

Information

1

Introduction

With the publication of the European technical guideline for the anchorage of post-installed metal fasteners in concrete (European Organization for Technical Approvals (EOTA) (1997)) for the first time it was possible to release European approvals for post-installed fasteners. The practical application of these approvals requires detailed design rules. At this time no European design provisions existed for fastenings and the development of generally acknowledged European design rules was not to be expected at short notice. Therefore, the design of fastenings had also to be covered in this guideline. The design method for post-installed fasteners published in Appendix C is based to a high extent on a guideline of the Deutsches Institut für Bautechnik (DIBt, German Institute of Construction Technology) from 1993 (Deutsches Institut f ür Bautechnik (1993)). During the past years Annex C was updated several times to the actual state of knowledge (European Organization for Technical Approvals (EOTA) (2010a)) and supplemented by the Technical Report TR 029 (European Organization for Technical Approvals (EOTA), 2010b) for the design of post-installed chemical fasteners. The current versions date from September, 2010.

The first European technical approvals for headed bolts were released in 2003. The design procedure for headed bolts was essentially based on Annex C of the above mentioned guideline and extended by applications specific to headed fasteners. This design method was a component of the approval document. These approval documents were replaced in 2011 by new versions which refer to the design provisions of CEN/TS 1992-4 as design procedure.

European technical approvals for anchor channels exist since 2011. They contain the design provisions of CEN/TS 1992-4 with slight improvements.

From the beginning the persons in charge were aware that the consideration of the design within the scope of an approval guideline could be only an interim solution, because after the European Construction Products Directive, EOTA was assigned to provide only European technical approval guidelines (ETAGs) for building products. The publication of European regulations for the design of construction products is within the responsibility of CEN. Hence, ETAG 001, Annex C should be transferred in the medium term into a European design standard. Finally in 2000 under the responsibility of CEN/TC 250 “Structural Eurocodes” this work started and was finalized in 2009. In May 2009 CEN/TS 1992-4 was accepted by the European Committee for standardization (CEN) for the tentative use as a pre-standard. The German version was published in August, 2009 by DIN (German Institute for Standardization) titled DIN SPEC 1021-4 (Deutsches Institut für Normung (DIN), 2009).

The published set of rules CEN/TS 1992-4 is a European pre-standard (TS=Technical Specification, in the past named prEN). In this publication it is called CEN/TS. CEN/TS consists of the following five parts:

– CEN/TS 1992-4-1:2009: General

– CEN/TS 1992-4-2:2009: Headed Fasteners

– CEN/TS 1992-4-3:2009: Anchor Channels

– CEN/TS 1992-4-4:2009: Post-installed Fasteners – mechanical Systems

– CEN/TS 1992-4-5:2009: Post-installed Fasteners – chemical Systems.

Part 1 is valid for all types of fasteners. Parts 2 to 5 contain special rules for the respective fasteners. These parts shall be applied only in connection with Part 1.

Although CEN/TS 1992-4 is a pre-standard, it may be already applied for the design of fastenings, provided that their suitability was verified for the intended application by a ETA. The respective ETA must refer to CEN/TS and contain all data necessary for the calculation. The ETA can be a so-called European Technical Approval (ETA), a European harmonized product standard (hEN) or a suitable national standard or regulation. The use of the post-installed fasteners, headed bolts and anchor channels covered by CEN/TS is regulated currently only by European Technical Approvals which are called in the following ETA (European Technical Approval). Other ETAs are not available currently. They are also not in the planning stage.

In the following CEN/TS provisions are explained. Detailed descriptions of the load bearing behaviour and procedures for the calculation of fastenings with mechanical and chemical post-installed fasteners, headed bolts and anchor channels can be found in Eligehausen and Mallée (2000) as well as Eligehausen, Mallée, and Silva (2006).

2

Fields of Application

CEN/TS covers the design of post-installed fastenings (fasteners) and cast in situ fasteners (headed fasteners and anchor channels) in concrete components. The following types of fasteners are considered:

– expansion fasteners, undercut fasteners, concrete screws, bonded fasteners, bonded expansion fasteners and bonded undercut fasteners

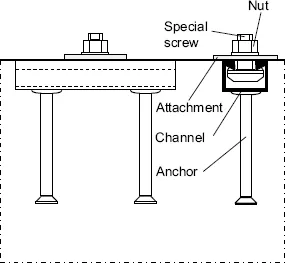

– headed bolts as well as anchor channels with stiff connection of anchorage element and channel.

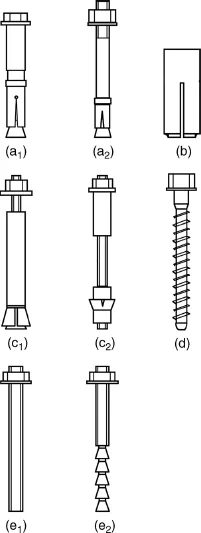

In Figure 2.1 the different types of post-installed fasteners are shown schematically, Figures 2.2 and 2.3 show typical headed fasteners and anchor channels.

Fig. 2.1 Types of post-installed fasteners

(a1) torque-controlled fastener (sleeve type)

(a2) torque-controlled fastener (bolt type, also named or wedge type)

(b) deformation-controlled fastener (drop-in fastener)

(c1) undercut fastener (undercut in the direction to the bottom of the borehole enlarged)

(c2) undercut fastener (undercut in the direction to the concrete surface enlarged)

(d) concrete screw

(e1) bonded fastener

(e2) bonded expansion fastener

(a1) torque-controlled fastener (sleeve type)

(a2) torque-controlled fastener (bolt type, also named or wedge type)

(b) deformation-controlled fastener (drop-in fastener)

(c1) undercut fastener (undercut in the direction to the bottom of the borehole enlarged)

(c2) undercut fastener (undercut in the direction to the concrete surface enlarged)

(d) concrete screw

(e1) bonded fastener

(e2) bonded expansion fastener

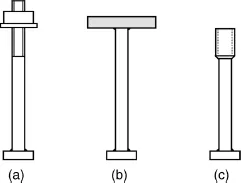

Fig. 2.2 Typical headed fasteners

Fig. 2.3 Typical anchor channel

Torque-controlled post-installed expansion fasteners are subdivided into sleeve type and bolt (wedge) type expansion fasteners. Post-installed fasteners of the sleeve type (Figure 2.1a1) consist of a screw or a threaded rod with nut, washer, distance sleeve, a part to prevent spinning of the fastener in the borehole as well as an expansion cone. Post-installed fasteners of the bolt type (Figure 2.1a2) consist of a bolt, the end of which is formed to one or two cones and shows at the other end a thread, expansion segments nested in the conical area of the bolt, as well as of a nut and a washer. The fasteners are anchored by applying a defined torque. During torqueing a prestressing force is generated in the bolt or in the screw, the cone or the cones at the end of the fastener is pulled into the expansion sleeve or segments. These are pressed against the borehole wall. The frictional forces caused thereby, fix the fasteners in the bore hole. The load-transfer mechanism employed by expansion anchors is called ‘friction’.

Displacement-controlled post-installed fasteners (Figure 2.1b) consist of an expansion sleeve and a conical expansion plug. The internally threaded steel sleeve allows to screw in a screw or a threaded rod. They are set via the expansion of the sleeve as controlled by the axial displacement of the expansion plug within the sleeve. This is achieved by driving the expansion plug into the sleeve with a setting tool and a hammer. Like torque-controlled expansion fasteners, displacement-controlled expansion fasteners transfer external tension loads into the base material via friction and, in the zone of the localised deformation to some degree via mechanical interlock.

Undercut fasteners develop a mechanical interlock between anchor and base material (working principle ‘mechanical interlock’). For this a cylindrically drilled hole is modified to create a notch, or undercut, of a specific dimension at a defined location either by means of a special drilling tool or by the undercutting action of the fastener itself (self-undercutting fastener). The Figures 2.1c1 and c2 show two typical undercut fasteners which differ for example in the direction of the undercut: Undercut that widens towards the bottom of the borehole (Figure 2.1c1) or towards the concrete surface (Figure 2.1c2). Undercut fasteners according to Figure 2.1c1 consist of a threaded stud with a conical end, expansion sleeve, nut, and washer. Internally threaded versions (not illustrated) accept bolts or threaded rods. This type of undercut fasteners is anchored by driving the expansion sleeve onto the conical end. Then the expansion sleeve fills the undercut area either produced with the help of a special tool or by cutting its undercut automatically by means of hammering or hammering/rotary action in the concrete. Undercut fasteners after Figure 2.1c2 consist of a threaded rod with hex nut and washer, a cylindrical nut, three curved bearing segments, cone, spacer sleeve, helical spring and a plastic ring which secures the bearing segments prior to installing the anchor. After drilling a cylindrical hole, the undercut is created with the help of a special undercutting tool. Afterwards the anchor is inserted into the borehole and the bearing elements are allowed to unfold into position at the level of the undercut. Defined torqueing of the fastener brings the bearing segments into contact with the supporting surfaces.

Concrete screws (Figure 2.1d) are screwed into pre-drilled holes with the help of a special impact power screwdriver, an electric power screwdriver, a hammer drill equipped with an adapter in rotary mode or a customary torque wrench. They show typically a hardened special thread to allow the process of cutting the threads into the concrete. The diameter of the drilled hole is matched to the geometry of the screw so that the thread cuts into the concrete and an external force can be transferred to the concrete by means of mechanical interlock.

Bonded fasteners (Figure 2.1e1) consist of a threaded rod, a hexagonal nut and a washer or an internally threaded sleeve to accept threaded parts as well as a chemical mortar as bonding material. The bonding materials may consist of polymer resins, cementitious materials, or a combination of the two. A distinction can be made between so-called capsule fasteners, in which the constituent bonding materials are contain...

Table of contents

- Cover

- Related Titles

- Title Page

- Copyright

- Editorial

- Chapter 1: Introduction

- Chapter 2: Fields of Application

- Chapter 3: Basis of Design

- Chapter 4: Derivation of Forces Acting on Fasteners

- Chapter 5: Verification of Ultimate Limit State by Elastic Analysis for Post-Installed Fasteners (Mechanical Systems)

- Chapter 6: Verification of Post-Installed Fasteners (Chemical Systems) for the Ultimate Limit State Based on the Theory of Elasticity

- Chapter 7: Verification of Ultimate Limit State by Elastic Analysis for Headed Fasteners

- Chapter 8: Verification of Ultimate Limit State by Elastic Analysis for Anchor Channels

- Chapter 9: Plastic Design Approach, Fastenings with Headed Fasteners and Post-Installed Fasteners

- Chapter 10: Durability

- Chapter 11: Exposure to Fire

- Chapter 12: Seismic Loading

- Chapter 13: Outlook

- References

- Index