In the last decades the application field of pressure-sensitive products (PSP) has been very enlarged. The end use tailored products gained an important market segment. For such products special recipes and technologies were developed. Some of them include a high level of empirical knowledge. Simultaneous advances in the macromolecular science and polymer engineering enabled the explanation of the function mechanismus of such products and the reasons for the special construction of several products. The theoretical basis of pressure-sensitive technology allowed the use of less expensive formulation for improved pressure-sensitive products. For a better understanding of their function and formulation we first consider the construction, and the physical and chemical basis of PSPs.

The definition, construction, physical and chemical basis of pressure-sensitive products are described in detail in our previous works [1,2]. Such products are characterized by special bonding and debonding mechanismus given by a permanently fluid status and viscoelasticity of the polymer. The pressure sensitivity of such products may be the attribute of a product component or of the whole product assembly. There are pressure-sensitive products with or without pressure-sensitive adhesives (PSA). It is evident that the build up of PSPs containing PSA differs from the construction of the adhesiveless self-adhesive products (SAP). The classical manufacture technology of pressure-sensitive products is based on the coating of pressure-sensitive adhesive on weblike, solid state carrier materials. Therefore the classical formulation science and technology cover the principles and practice of the PSA formulation. The development of high polymer films allowed the manufacture of self-adhesive carrier materials. Their formulation was worked out by the industry of plastics processing. Advances in the composite materials forced the development of self supporting adhesive structures, i.e. of the carrierless PSPs. Thus two different pressure-sensitive technologies appeared.

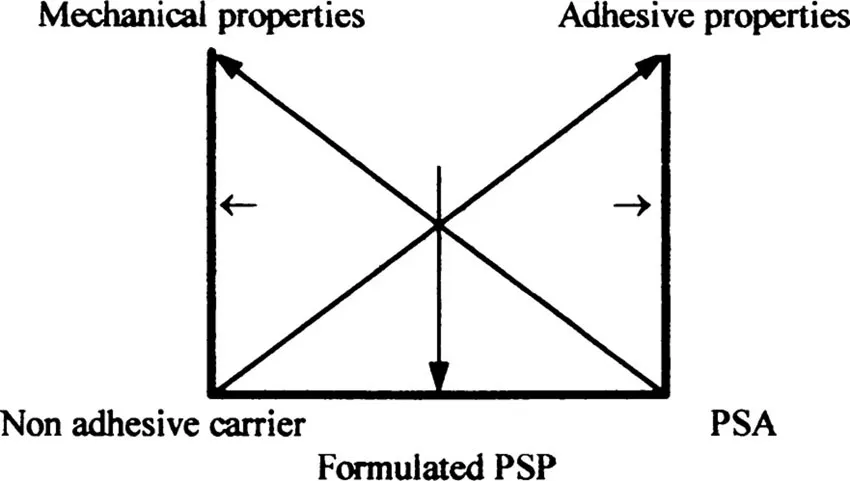

Independently of their build up and manufacture technology such products have to exhibit surface related pressure sensitivity (i.e. deformability) and mechanical characteristics which ensure their application (bonding and debonding). Therefore the first problem of the formulation of PSPs is the design of an adequate balance between the adhesive and mechanical performance characteristics (Figure 1.1).

Another problem concerns the design of pressure sensitivity and its regulation. In the recent status of technical development the manufacture by coating of PSA is the predominant production technology of PSPs, although special products are manufactured by plastic processing technologies (e.g. extrusion and injection moulding). Therefore the majority of manufacturers consider the formulation of PSPs as formulation of the pressure-sensitive adhesive.

As discussed in a detailed manner in [1,2] the viscoelasticity necessary for pressure sensitivity of an adhesive is provided by special chemical and macromolecular build up. Viscoelasticity is the resultant of viscous „free” flow (i.e. of advanced inter and intramolecular mobility) and of its hindrance by ordered structures.

1 POLYMER RELATED CHARACTERISTICS OF PRESSURE SENSITIVITY

Molecular mobility and its hindrance depend on molecular (chemical) build up and on molecular dimensions (i.e. on chemical composition and molecular weight).The molecular polarity and reactivity and the molecular weight and its distribution are the main parameters of macromolecular products. Their regulation leads to products with viscous or elastomeric character. Molecular weight regulation during the synthesis of macromolecular compounds can provide products having the same chemical composition and (related to their different molecular weight), a viscous, viscoelastical or elastical behaviour (e.g. polybutenes). In principle, such regulation is possible during the synthesis of pressure-sensitive raw materials, i.e. it is possible to synthesize macromolecular compounds having ab ovo a balanced viscoelastical character. Theoretically such macromolecular compounds do not need formulation. Really in the industrial practice there are only a few ready to use viscoelastical compounds, the main part of raw materials require the tailoring of their viscoelastical properties via formulation.

How to characterize the „degree” of viscoelasticity and pressure sensitivity? The manufacturer of pressure-sensitive products can test its finished materials in order to control their pressure sensitivity. In special cases the pressure-sensitive character of the raw materials can be tested too. However, generally, only the test of the viscous or elastical character of such base materials is possible. Although the viscous or elastical character of a product is reflected by its practical (e.g. mechanical) properties also, there is a need to correlate the macroscopically measurable material characteristics to the intrinsic build up of a macromolecular product i.e. to the polymer characteristics. The „tools” for such correlating are given by the glass transition temperature (Tg) and modulus of the material.

1.1 Glass transition temperature

The glass transition temperature characterizes a second order transition, that of the molecular mobility. Above this temperature the molecular mobility is improved and the macromolecular compound may suffer viscoelastical deformation. Above the Tg coalescence, tackiness and rubberlike elasticity appear. The position of the glass transition temperature is an index of the molecular mobility and pressure sensitivity. The hardness and stiffness of polymers incresases with the Tg [3]. Adhesion strongly depends on the temperature and ...