eBook - ePub

Two-Stroke Cycle Engine

It's Development, Operation and Design

JohnB. Heywood

This is a test

Buch teilen

- 472 Seiten

- English

- ePUB (handyfreundlich)

- Über iOS und Android verfügbar

eBook - ePub

Two-Stroke Cycle Engine

It's Development, Operation and Design

JohnB. Heywood

Angaben zum Buch

Buchvorschau

Inhaltsverzeichnis

Quellenangaben

Über dieses Buch

This book addresses the two-stroke cycle internal combustion engine, used in compact, lightweight form in everything from motorcycles to chainsaws to outboard motors, and in large sizes for marine propulsion and power generation. It first provides an overview of the principles, characteristics, applications, and history of the two-stroke cycle engine, followed by descriptions and evaluations of various types of models that have been developed to predict aspects of two-stroke engine operation.

Häufig gestellte Fragen

Wie kann ich mein Abo kündigen?

Gehe einfach zum Kontobereich in den Einstellungen und klicke auf „Abo kündigen“ – ganz einfach. Nachdem du gekündigt hast, bleibt deine Mitgliedschaft für den verbleibenden Abozeitraum, den du bereits bezahlt hast, aktiv. Mehr Informationen hier.

(Wie) Kann ich Bücher herunterladen?

Derzeit stehen all unsere auf Mobilgeräte reagierenden ePub-Bücher zum Download über die App zur Verfügung. Die meisten unserer PDFs stehen ebenfalls zum Download bereit; wir arbeiten daran, auch die übrigen PDFs zum Download anzubieten, bei denen dies aktuell noch nicht möglich ist. Weitere Informationen hier.

Welcher Unterschied besteht bei den Preisen zwischen den Aboplänen?

Mit beiden Aboplänen erhältst du vollen Zugang zur Bibliothek und allen Funktionen von Perlego. Die einzigen Unterschiede bestehen im Preis und dem Abozeitraum: Mit dem Jahresabo sparst du auf 12 Monate gerechnet im Vergleich zum Monatsabo rund 30 %.

Was ist Perlego?

Wir sind ein Online-Abodienst für Lehrbücher, bei dem du für weniger als den Preis eines einzelnen Buches pro Monat Zugang zu einer ganzen Online-Bibliothek erhältst. Mit über 1 Million Büchern zu über 1.000 verschiedenen Themen haben wir bestimmt alles, was du brauchst! Weitere Informationen hier.

Unterstützt Perlego Text-zu-Sprache?

Achte auf das Symbol zum Vorlesen in deinem nächsten Buch, um zu sehen, ob du es dir auch anhören kannst. Bei diesem Tool wird dir Text laut vorgelesen, wobei der Text beim Vorlesen auch grafisch hervorgehoben wird. Du kannst das Vorlesen jederzeit anhalten, beschleunigen und verlangsamen. Weitere Informationen hier.

Ist Two-Stroke Cycle Engine als Online-PDF/ePub verfügbar?

Ja, du hast Zugang zu Two-Stroke Cycle Engine von JohnB. Heywood im PDF- und/oder ePub-Format sowie zu anderen beliebten Büchern aus Technology & Engineering & Civil Engineering. Aus unserem Katalog stehen dir über 1 Million Bücher zur Verfügung.

Information

CHAPTER

ONE

OVERVIEW, BACKGROUND, AND HISTORY

Internal combustion engines are used to produce mechanical power from the chemical energy contained in hydrocarbon fuels. The power-producing part of the engine’s operating cycle starts inside the engine’s cylinders with a compression process. Following this compression, the burning of the fuel–air mixture then releases the fuel’s chemical energy and produces high-temperature, high-pressure combustion products. These gases then expand within each cylinder and transfer work to the piston. Thus, as the engine is operated continuously, mechanical power is produced.

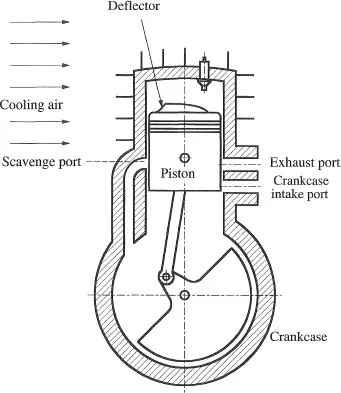

Almost all internal combustion engines utilize the reciprocating piston-in-cylinder geometry shown in Fig. 1-1. The oscillating motion of the piston is converted to the rotary motion needed to transmit mechanical power, through the connecting rod and crankshaft arrangement shown. Each upward or downward movement of the piston is called a stroke. There are two commonly used internal combustion engine cycles: the two-stroke cycle and the four-stroke cycle. Both cycles are based on the preceding description of the essential power-producing sequence: compression of the unburned mixture, its combustion, and then expansion as burned gases.

The fundamental difference between these two cycles is in their gas exchange process: that is, the removal of burned gases at the end of each expansion process and the induction of fresh mixture for the next cycle. The two-stroke has an expansion, or power, stroke in each cylinder during each revolution of the crankshaft, and the exhaust and the charging processes occur simultaneously as the piston moves through its lowest, or bottom center (BC), position shown in Fig. 1-1. In the four-stroke cycle, the burned gases are first displaced by the piston during an upward exhaust stroke and the fresh charge then enters the cylinder during the following downward intake stroke. It is the two-stroke cycle engine that is the subject of this book.

Figure 1-1 A crankcase-scavenged two-stroke cycle engine.

There are two basic types of internal combustion engine: the spark-ignition engine (sometimes called the Otto-cycle engine), and the compression-ignition engine, which is often called the diesel. In the spark-ignition engine, the fuel–air mixture is essentially premixed prior to combustion, which is initiated with a spark discharge. In the diesel, air alone is inducted and compressed; fuel is injected into the cylinder just before combustion commences. The injected fuel vaporizes and mixes rapidly with the high-temperature compressed air and spontaneously ignites, burning as it mixes. The two-stroke cycle is used in both spark-ignition and diesel engines.

The two-stroke cycle is hardly a new concept; in fact, all internal combustion engines developed before Nicolaus Otto invented the four-stroke cycle engine in 1876 operated on a two-stroke cycle. Today, the two-stroke engine is a refined power unit that offers high performance while being compact, simple, and lightweight. The largest (~ 30,000 MW) and the smallest (~ 15 W) reciprocating piston engines in the world use the two-stroke cycle.

If it were possible to run a two-stroke cycle engine at the same crankshaft rotational speed and work production per unit of displaced cylinder volume as a four-stroke cycle engine, the two-stroke would develop twice as much power as a four-stroke of the same size because the number of cycles per unit time would be twice as large. However, because in the two-stroke cycle engine the burned gases are pushed out from the cylinder by the entering fresh charge, losses due to mixing of fresh charge and burned gases are unavoidable, and the theoretical power advantage of the two-stroke engine over its four-stroke counterpart cannot be fully realized.

1-1 PRINCIPLES OF THE TWO-STROKE CYCLE ENGINE

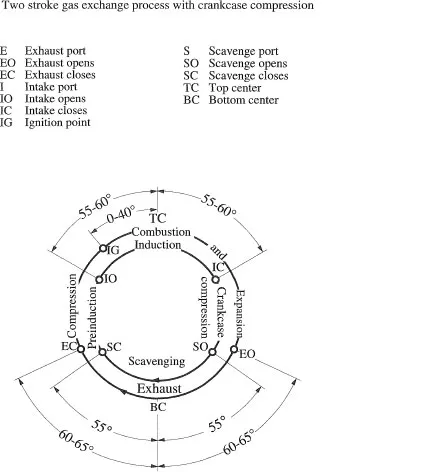

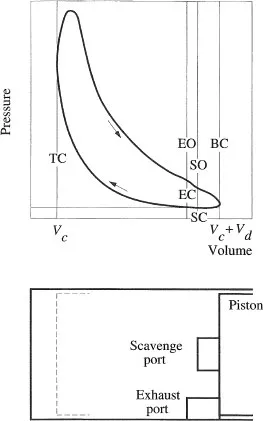

As the two-stroke cycle lacks separate intake and exhaust strokes, a scavenging pump is required to drive the fresh charge into the cylinder. In one of the simplest and most frequently used types of two-stroke engine designs, the bottom surface of the piston in conjunction with that portion of the crankcase beneath each cylinder is used as the scavenging pump. Figure 1-2 shows the typical sequence of cycle events in this type of engine, and Fig. 1-3 relates these events to a cylinder-pressure versus cylinder-volume trace and the port positions along the liner. The cycle begins while the piston is travelling upward toward the top center (TC) crank position, and the crankcase intake port is uncovered by the piston (IO in Fig. 1-2). Fresh charge (either air or fuel–air mixture) enters into the crankcase through the intake manifold while the charge within the cylinder continues to be compressed by the upper part of the piston. The charge is then ignited (either by an electrical discharge in a spark-ignition engine or by a spontaneous ignition process in a diesel), combustion occurs and the burned gases in the cylinder expand as the piston travels toward bottom center (BC). At the same time, as the crankcase volume decreases and the intake port is still open, some of the fresh charge may escape to the atmosphere through the intake manifold in a reverse flow. Approximately 60° after TC, the inlet port closes (IC), and the fresh mixture in the crankcase is then compressed. The in-cylinder gas exchange process begins as the exhaust port is opened (EO). As the piston continues its downward travel, it then opens the scavenge or transfer ports. When both the scavenge and exhaust ports are open, the cylinder is subjected to a pressure gradient that simultaneously governs the inflow and outflow streams through the open ports. During this period—the scavenging period—the compressed fresh charge in the crankcase flows through the transfer ducts into the cylinder and scavenges the burned combustion products out of the cylinder through the exhaust port. The ports and the projection on the piston (the deflector) are shaped so that most of the fresh charge will sweep up to the top of the cylinder before flowing to the exhaust port. This is done to scavenge the combustion products more completely from the upper part of the cylinder and prevent significant amounts of the fresh charge from flowing directly to the exhaust port, a process called short-circuiting. In the second half of this period, the piston travels upward, the crankcase volume increases, and a reverse flow from the cylinder to the crankcase through the scavenge ports may occur depending on the charging pressure and engine speed. The gas exchange process is completed when the piston covers up and closes the exhaust port (EC).

Figure 1-2 Typical sequence of two-stroke cycle events: The outer circle shows the processes occurring inside the cylinder as a function of crank angle; the inner circle shows those occurring in the crankcase. Developed from Bosch Automotive Handbook.1

Figure 1-3 Cylinder-pressure versus cylinder-volume trace of a two-stroke cycle engine.

An alternative to using the crankcase to compress the fresh charge prior to scavenging is to employ an external pump. A positive displacement Roots blower can be used, or a centrifugal compressor, driven from the crankshaft. In larger two-stroke cycle engines a blower and a turbocharger can be combined together. The crankshaft-driven blower provides compression for startin...