eBook - ePub

Metal Foams: A Design Guide

Michael F. Ashby, Tony Evans, NA Fleck, J.W. Hutchinson, H.N.G. Wadley, L. J. Gibson

This is a test

Buch teilen

- 251 Seiten

- English

- ePUB (handyfreundlich)

- Über iOS und Android verfügbar

eBook - ePub

Metal Foams: A Design Guide

Michael F. Ashby, Tony Evans, NA Fleck, J.W. Hutchinson, H.N.G. Wadley, L. J. Gibson

Angaben zum Buch

Buchvorschau

Inhaltsverzeichnis

Quellenangaben

Über dieses Buch

Metal foams are at the forefront of technological development for the automotive, aerospace, and other weight-dependent industries. They are formed by various methods, but the key facet of their manufacture is the inclusion of air or other gaseous pockets in the metal structure.

The fact that gas pockets are present in their structure provides an obvious weight advantage over traditionally cast or machined solid metal components. The unique structure of metal foams also opens up more opportunities to improve on more complex methods of producing parts with space inclusions such as sand-casting. This guide provides information on the advantages metal foams possess, and the applications for which they may prove suitable.

- Offers a concise description of metal foams, their manufacture, and their advantages in industry

- Provides engineers with answers to pertinent questions surrounding metal foams

- Satisfies a major need in the market for information on the properties, performance, and applications of these materials

Häufig gestellte Fragen

Wie kann ich mein Abo kündigen?

Gehe einfach zum Kontobereich in den Einstellungen und klicke auf „Abo kündigen“ – ganz einfach. Nachdem du gekündigt hast, bleibt deine Mitgliedschaft für den verbleibenden Abozeitraum, den du bereits bezahlt hast, aktiv. Mehr Informationen hier.

(Wie) Kann ich Bücher herunterladen?

Derzeit stehen all unsere auf Mobilgeräte reagierenden ePub-Bücher zum Download über die App zur Verfügung. Die meisten unserer PDFs stehen ebenfalls zum Download bereit; wir arbeiten daran, auch die übrigen PDFs zum Download anzubieten, bei denen dies aktuell noch nicht möglich ist. Weitere Informationen hier.

Welcher Unterschied besteht bei den Preisen zwischen den Aboplänen?

Mit beiden Aboplänen erhältst du vollen Zugang zur Bibliothek und allen Funktionen von Perlego. Die einzigen Unterschiede bestehen im Preis und dem Abozeitraum: Mit dem Jahresabo sparst du auf 12 Monate gerechnet im Vergleich zum Monatsabo rund 30 %.

Was ist Perlego?

Wir sind ein Online-Abodienst für Lehrbücher, bei dem du für weniger als den Preis eines einzelnen Buches pro Monat Zugang zu einer ganzen Online-Bibliothek erhältst. Mit über 1 Million Büchern zu über 1.000 verschiedenen Themen haben wir bestimmt alles, was du brauchst! Weitere Informationen hier.

Unterstützt Perlego Text-zu-Sprache?

Achte auf das Symbol zum Vorlesen in deinem nächsten Buch, um zu sehen, ob du es dir auch anhören kannst. Bei diesem Tool wird dir Text laut vorgelesen, wobei der Text beim Vorlesen auch grafisch hervorgehoben wird. Du kannst das Vorlesen jederzeit anhalten, beschleunigen und verlangsamen. Weitere Informationen hier.

Ist Metal Foams: A Design Guide als Online-PDF/ePub verfügbar?

Ja, du hast Zugang zu Metal Foams: A Design Guide von Michael F. Ashby, Tony Evans, NA Fleck, J.W. Hutchinson, H.N.G. Wadley, L. J. Gibson im PDF- und/oder ePub-Format sowie zu anderen beliebten Büchern aus Tecnología e ingeniería & Ingeniería minera. Aus unserem Katalog stehen dir über 1 Million Bücher zur Verfügung.

Information

Thema

Ingeniería mineraChapter 1

Introduction

Metal foams are a new, as yet imperfectly characterized, class of materials with low densities and novel physical, mechanical, thermal, electrical and acoustic properties. They offer potential for lightweight structures, for energy absorption, and for thermal management; and some of them, at least, are cheap. The current understanding of their production, properties and uses in assembled in this Design Guide. The presentation is deliberately kept as simple as possible. Section 1.1 expands on the philosophy behind the Guide. Section 1.2 lists potential applications for metal foams. Section 1.3 gives a short bibliography of general information sources; further relevant literature is given in the last section of each chapter.

At this point in time most commercially available metal foams are based on aluminum or nickel. Methods exist for foaming magnesium, lead, zinc, copper, bronze, titanium, steel and even gold, available on custom order. Given the intensity of research and process development, it is anticipated that the range of available foams will expand quickly over the next five years.

1.1 This Design Guide

Metallic foams (‘metfoams’) are a new class of material, unfamiliar to most engineers. They are made by a range of novel processing techniques, many still under development, which are documented in Chapter 2. At present metfoams are incompletely characterized, and the processes used to make them are imperfectly controled, resulting in some variability in properties. But even the present generation of metfoams have property profiles with alluring potential, and the control of processing is improving rapidly. Metfoams offer significant performance gains in light, stiff structures, for the efficient absorption of energy, for thermal management and perhaps for acoustic control and other, more specialized, applications (Section 1.2). They are recyclable and nontoxic. They hold particular promise for market penetration in applications in which several of these features are exploited simultaneously.

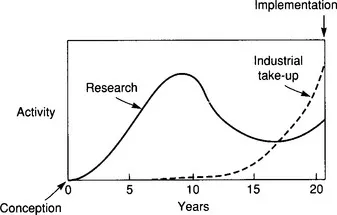

But promise, in today’s competitive environment, is not enough. A survey of the history of development of new material suggests a scenario like that sketched in Figure 1.1. Once conceived, research on the new material accelerates rapidly, driven by scientific curiosity and by the often over-optimistic predictions of its potential impact on engineering. The engineering take-up, however, is slow, held back by lack of adequate design data, experience and confidence; the disappointing take-up leads, after some 5 or 10 years, to disillusionment and a decline in research funding and activity. On a longer time-scale (15 years is often cited as the typical gestation period) the use of the new material – provided it has real potential – takes hold in one or more market sectors, and production and use expands, ultimately pulling research and development programmes with it.

Figure 1.1 A development history typical of many new materials. Research into the new material grows rapidly, and then slumps when little interest is shown by industry in using it. On a longer (15-year) time scale, applications slowly emerge

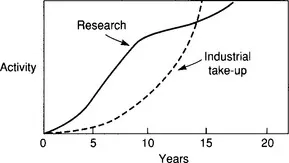

There are obvious reasons for seeking a better balance between research and engineering take-up. This Design Guide is one contribution to the effort to achieve faster take-up, to give development curves more like those of Figure 1.2. Its seeks to do this by

Figure 1.2 A more attractive development history than that of Figure 1.1. Early formulation of design rules, research targeted at characterizing the most useful properties, and demonstrator projects pull the ‘take-up’ curve closer to the ‘research’ curve

• Presenting the properties of metallic foams in a way which facilitates comparison with other materials and structures

• Summarizing guidelines for design with them

• Illustrating how they might be used in lightweight structures, energy-absorbing systems, thermal management and other application, using, where possible, case studies.

The Guide starts with a description of the ways in which metfoams are made (Chapter 2) and the methods and precautions that have evolved for testing and characterizing them (Chapter 3). It continues with a summary of material properties, contrasting those of metfoams with those of other structural materials (Chapter 4). Chapter 5 outlines design analysis for materials selection. This is followed in Chapter 6 by a summary of formulae for simple structural shapes and loadings; the ways in which the properties of metal foams influence the use of these formulae are emphasized.

Mechanical design with foams requires constitutive equations defining the shape of the yield surface, and describing response to cyclic loading and to loading at elevated temperatures. These are discussed in

Chapters 7, 8 and 9. One potential application for foams is that as the core for sandwich beams, panels and shells. Chapter 10 elaborates on this, illustrating how the stiffness and strength of weight-optimized sandwich structures compare with those of other types. Chapters 11, 12 and 13 outline the use of metal foams in energy, acoustic and thermal management. Chapter 14 describes how they can be cut, finished and joined. Chapter 15 discusses economic aspects of metal foams and the way economic and technical assessment are combined to establish viability. Chapter 16 reports case studies illustrating successful and potential applications of metal foams. Chapter 17 contains a list of the suppliers of metal foams, with contact information. Chapter 18 lists Web sites of relevant research groups and suppliers. The Guide ends with an Appendix in which material indices are catalogued.

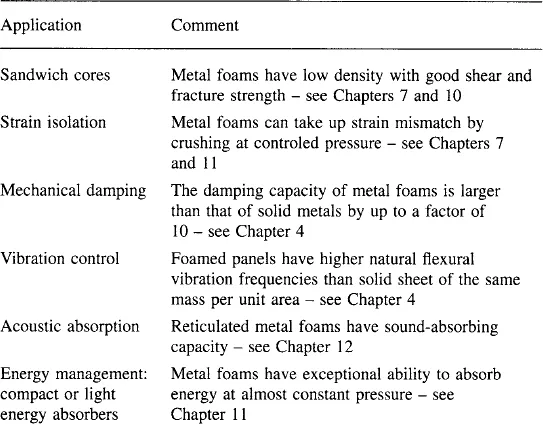

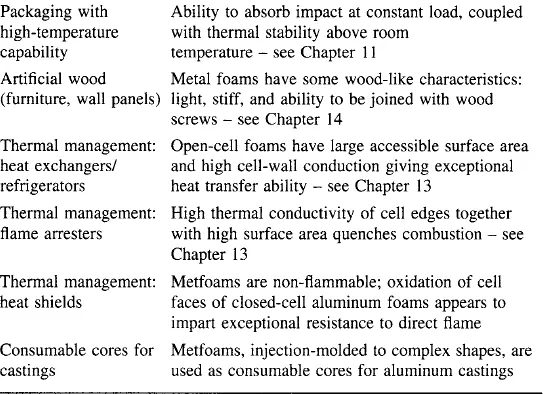

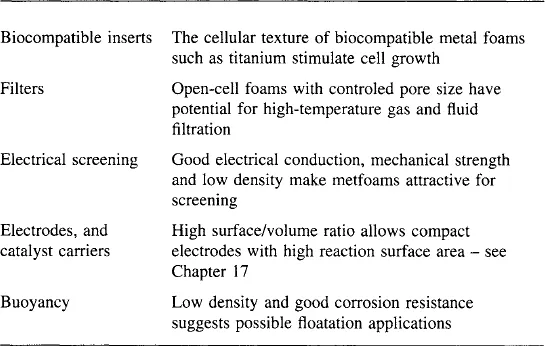

1.2 Potential applications for metal foams

1.3 The literature on metal foams

The body of literature on metal foams is small, but growing quickly. The selection below gives sources that provide a general background. Specific references to more specialized papers and reports are given at the end of the chapter to which they are relevant.

Banhart J., ed. Metallschäume. Bremen: MIT Verlag, 1997.

Banhart J., Ashby M. F., Fleck N. A., eds. Metal Foams and Foam Metal Structures, Proc. Int. Conf. Metfoam’99. ...