eBook - ePub

Understanding Wood Finishing, 3rd Revised Edition

How to Select and Apply the Right Finish

Bob Flexner

This is a test

Buch teilen

- 250 Seiten

- English

- ePUB (handyfreundlich)

- Über iOS und Android verfügbar

eBook - ePub

Understanding Wood Finishing, 3rd Revised Edition

How to Select and Apply the Right Finish

Bob Flexner

Angaben zum Buch

Buchvorschau

Inhaltsverzeichnis

Quellenangaben

Über dieses Buch

Nicknamed the "Bible" of wood finishing, Understanding Wood Finishing is a best-selling, easy-to-understand resource that teaches readers everything they need to know, from preparing and staining wood to different types of wood finishes, coloring techniques, filling pores, removing finishes, and more. This newly updated edition features a collection of published articles written by Bob from the last few years.

Häufig gestellte Fragen

Wie kann ich mein Abo kündigen?

Gehe einfach zum Kontobereich in den Einstellungen und klicke auf „Abo kündigen“ – ganz einfach. Nachdem du gekündigt hast, bleibt deine Mitgliedschaft für den verbleibenden Abozeitraum, den du bereits bezahlt hast, aktiv. Mehr Informationen hier.

(Wie) Kann ich Bücher herunterladen?

Derzeit stehen all unsere auf Mobilgeräte reagierenden ePub-Bücher zum Download über die App zur Verfügung. Die meisten unserer PDFs stehen ebenfalls zum Download bereit; wir arbeiten daran, auch die übrigen PDFs zum Download anzubieten, bei denen dies aktuell noch nicht möglich ist. Weitere Informationen hier.

Welcher Unterschied besteht bei den Preisen zwischen den Aboplänen?

Mit beiden Aboplänen erhältst du vollen Zugang zur Bibliothek und allen Funktionen von Perlego. Die einzigen Unterschiede bestehen im Preis und dem Abozeitraum: Mit dem Jahresabo sparst du auf 12 Monate gerechnet im Vergleich zum Monatsabo rund 30 %.

Was ist Perlego?

Wir sind ein Online-Abodienst für Lehrbücher, bei dem du für weniger als den Preis eines einzelnen Buches pro Monat Zugang zu einer ganzen Online-Bibliothek erhältst. Mit über 1 Million Büchern zu über 1.000 verschiedenen Themen haben wir bestimmt alles, was du brauchst! Weitere Informationen hier.

Unterstützt Perlego Text-zu-Sprache?

Achte auf das Symbol zum Vorlesen in deinem nächsten Buch, um zu sehen, ob du es dir auch anhören kannst. Bei diesem Tool wird dir Text laut vorgelesen, wobei der Text beim Vorlesen auch grafisch hervorgehoben wird. Du kannst das Vorlesen jederzeit anhalten, beschleunigen und verlangsamen. Weitere Informationen hier.

Ist Understanding Wood Finishing, 3rd Revised Edition als Online-PDF/ePub verfügbar?

Ja, du hast Zugang zu Understanding Wood Finishing, 3rd Revised Edition von Bob Flexner im PDF- und/oder ePub-Format sowie zu anderen beliebten Büchern aus Technology & Engineering & Technical & Manufacturing Trades. Aus unserem Katalog stehen dir über 1 Million Bücher zur Verfügung.

Information

CHAPTER 1

Why Finish Wood,

Anyway?

In Brief

Why do we finish wood? It’s an extra step, or steps, that most woodworkers don’t find at all enjoyable. It’s smelly and messy, and all sorts of things can go wrong. In addition, most woods look pretty good unfinished. Why bother? There are three good reasons for finishing wood: to help keep it clean, to help stabilize it, and to decorate it.

Sanitation

Wood is a porous material. It contains countless holes of various sizes. These holes can accumulate dirt and grime from handling, atmospheric contaminants, and food. Grimy wood is unattractive, and it can be a health hazard, providing a breeding place for bacteria. A finish seals the porous surface, making it less susceptible to soiling and easier to clean.

Stabilization

Besides being porous, wood is hygroscopic: It absorbs and releases moisture. Moisture within wood is called moisture content; moisture in the environment is either liquid water or water vapor (humidity). Wood responds to changes in the level of moisture around it. If you put very dry wood in water or in an area of high humidity, the wood will absorb moisture and swell. If you put wood that has a high moisture content in a relatively dry climate, the wood will release moisture and shrink.

MYTH

Finishing both sides of wood prevents, or at least reduces, warping.

FACT

A finish will slow but will not prevent or reduce warping caused by wood shrinking more tangentially (around its growth rings) than radially (perpendicular to its growth rings). Moisture vapor will still work its way through the finish and cause the same degree of warping. Warping caused by compression shrinkage on the side more exposed to wetting and drying (usually the top side) won’t be hindered at all. This is the reason tabletops exposed to spills and water from wiping with damp cloths should be refinished whenever the finish begins to deteriorate or wear badly.

These dimensional changes, commonly called wood movement do not occur consistently throughout a piece of wood. The surface of wood, for instance, responds more readily than the core. Wood swells and shrinks mainly across the grain; that is, in the width and thickness of boards, not appreciably in the length. And wood swells and shrinks more around the annular growth rings than it does perpendicular to the rings. The result of these different responses is that wood movement generates great stresses in wood and on the joints that hold pieces of wood together. The stresses cause splitting, checking, warping, and weakening of the joints. A finish slows moisture exchange, thus reducing the stresses and stabilizing the wood.

As a general rule, the thicker the coating of finish, the better it limits moisture exchange. This exchange does not have to be in the form of liquid water. It can be, and usually is, water vapor. Water-vapor exchange causes much damage to otherwise sheltered wood furniture and woodwork. It just does this more slowly than in wood subjected to liquid-water exchange.

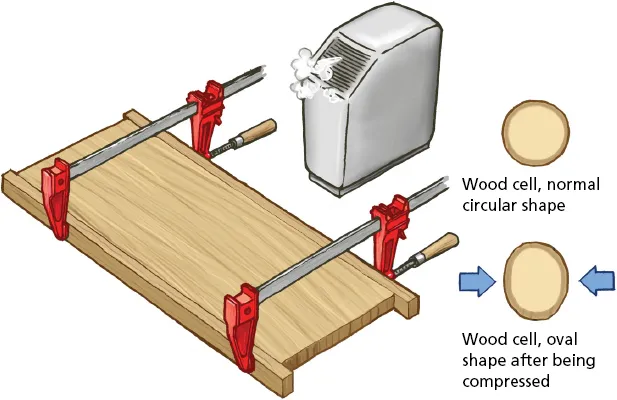

Figure 1-1: When dry wood is exposed to moisture, the cell walls swell. If the wood can’t expand, the cells compress.

Clamps restrain wood from expanding, simulating the constraint of metal fasteners, cross-grain construction, or simply differences in the moisture content between different areas of the wood.

Splits, Checks, and Warps

To understand better how moisture exchange causes splits, checks, and warps, look at Figure 1-1. A solid piece of kiln-dried wood is clamped securely so that it can’t expand in width. Then it is exposed to 100 percent humidity for a period of time. The cell walls swell and the wood tries to expand, but it is constrained by the clamps. So the cell walls compress, changing from cylindrical to oval in shape.

If the board is released from the clamps and the humidity dropped to 30 percent, water evaporates and the cell walls shrink. But the cells don’t return to their cylindrical shape: They remain flattened. So the board shrinks, becoming narrower than it was originally. If the board is reclamped and exposed again to high and then low humidity, it will shrink further. This phenomenon is called compression shrinkage (also compression set). It explains why nails and screws work loose in wood, and why the wooden handles of hammers and hatchets loosen over time, after continually absorbing and releasing moisture.

Compression shrinkage also accounts for splits developing in the ends of a board, checks in the middle of a board, and cupping (a type of warp) on the side of a board exposed to the most water (Photos 1-1 through 1-3). In each case part of the board comes in contact with water and tries to expand more than the rest of the board will allow it to. After a number of cycles of restricted expansion followed by full contraction, that part of the board changes shape or splits. Of course, these types of problems are less likely to occur if the finish is kept in good shape. Less water will be able to get to the wood.

TIP

Understanding the concept of compression shrinkage leads to the counterintuitive, but effective, method for correcting warps caused by repeated exposure to water on one side. Hold the board in clamps so it can’t expand; then wet the convex side (usually the bottom side of tabletops) many times, letting it dry after each. The convex side will be compressed and shrink, bringing the board flat.

Photo 1-1: When wood absorbs moisture, more is absorbed near the end than in the middle because the end grain is more porous than the other surfaces and because the end grain together with the nearby face grain presents more surface area. As a result, the end of a board is prone to expand more than the middle of a board. But the middle acts like a clamp on the end, causing compression shrinkage. After a number of cycles, the end of the board splits to relieve the stresses. You see this type of compression shrinkage on the ends of any boards exposed to repeated contact with water.

Photo 1-2: When moisture comes in contact with just part of a board, the wood cells in that part swell. But the surrounding wood acts like a clamp and prevents the swelling. This causes compression shrinkage and the resulting checks. You see this type of compression shrinkage on parts of tabletops subjected to repeated contact with water, as from a leaking potted plant.

Photo 1-3: When wood is exposed to more water on one side than the other, the imbalance causes cupping. The side exposed to the most moisture has its expansion restricted by the thickness of the board, resulting in compression shrinkage. You see this type of compression shrinkage on decks and tabletops, where the cupping is almost always on the top sid...