![]()

Chapter 1

Dairy Ingredients for Food Processing: An Overview

Ramesh C. Chandan

Introduction

Dairy ingredients are important players in the formulation of many food products. The addition of familiar dairy ingredients, widely recognized by the consumer as “natural,” enhances the odds of success of packaged foods in the marketplace. They generally deliver a consumer-friendly label on the package.

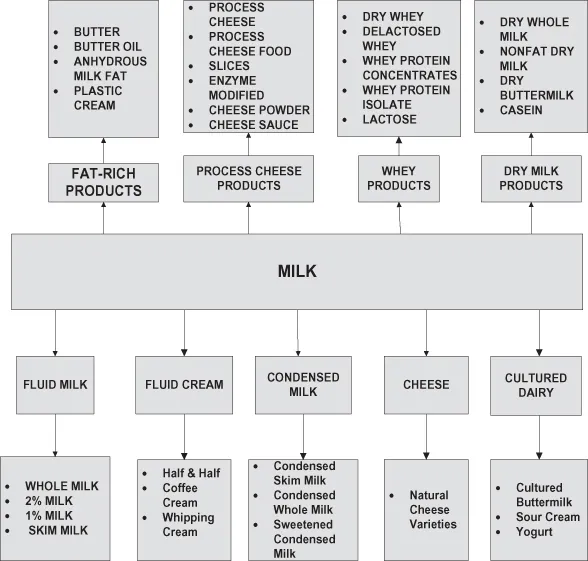

Dairy ingredients are derived from fluid milk in the form of cream, butter, condensed milk, dry milk, cheese, and whey products (Olson and Aryana, 2008, Sodini and Tong, 2006). They provide desirable functionality to foods, such as delivery of key nutrients, water management, fat-holding capacity, emulsification capability, viscosity creation, gel formation, and foam generation. In addition, dairy-based ingredients in liquid, concentrated, or dry form confer desirable attributes of texture and flavor to dairy foods, frozen desserts, puddings, processed meat, cereal products, chocolate confections, infant formulas, and an array of dietetic as well as geriatric drinks and bars. In conventional bakery items, dairy ingredients are used in enriched breads, croissants, milk bread, cakes, cookies, and pastries. Figure 1.1 demonstrates the relationship of milk to major dairy ingredients used for food processing.

Dairy ingredients contribute several critical characteristics associated with a food product. Caseinates impart emulsifying and stabilizing ability. Whey protein concentrates and isolates give gelling properties and furnish high-quality protein (Kilara, 2008). Similarly, milk protein concentrates provide a base of dietetic products. High-heat nonfat dry milk is reputed to impart water-absorption capacity to baked goods. Lactose-containing dairy ingredients are responsible for desirable brown crust in bread and other bakery items. Enzyme-modified butter and cheese flavor concentrates are used in food products for butter and cheese carryover. Dairy ingredients are important tools for a food developer to create certain desirable attributes in foods. An understanding of the functional properties of dairy ingredients allows food technologists to use their potential contributions to meet consumer expectations.

Consumer trends, especially in functional foods (Chandan and Shah, 2007) as well as fast and convenience foods, are shaping the development of new products in the marketplace. More recently, market opportunities have been leveraged in nutraceutical beverages for use as tools for weight management, meal replacement, and geriatric nutritional needs using fluid skim milk, nonfat dry milk, milk protein concentrate, and whey protein concentrate. In addition, coffee-based drinks have provided the consumer with a variety of nutritional and functional drinks.

In the arena of industrial ingredients, dairy plants fabricate convenient, custom-made mixes for food plants for processing of foods. Such practice is currently undertaken for the production of yogurt, ice cream, and confectionery products (Chandan and O’Rell, 2006a; Kilara and Chandan, 2008). Novel ingredients have been developed by applying membrane technology to fractionate milk and whey to enhance their performance in food products. Such ingredients furnish milk protein, milk fat, or milk minerals in food supplements. A new trend involves development of functional ingredients from whey, colostrum, and bioactive peptides from milk proteins, which possess distinct health-promoting attributes (Chandan 2007a and b). Other ingredients are specific metabolites concentrated in fermented milk or whey by the activity of specific dairy cultures. The dried fermented ingredients derived from fermented bases contain active metabolites that are used as natural preservatives to extend shelf life and safety of foods. The enzyme-modified cheeses are cheese flavor concentrates that are widely used in the production of cheese powders, cheese sauces, and process cheese, and in the preparation of fillings for cookies and crackers.

Milk and Dairy Processing

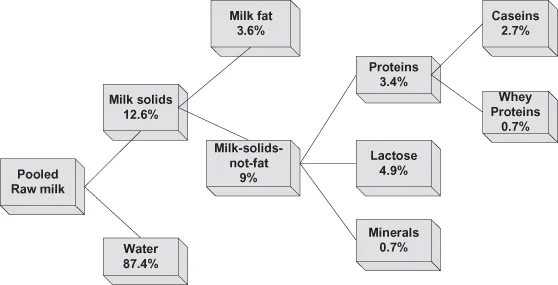

Fluid milk is a basic ingredient in dairy foods, including frozen and refrigerated desserts (Kilara and Chandan, 2008; Chandan and Kilara, 2008)). Many dairy-derived ingredients for use in food processing owe their origin to milk, which is comprised of water and milk solids. Milk solids are comprised of milk fat and milk-solids-not-fat. Figure 1.2 illustrates the gross composition of milk, showing major constituents. The composition of whole milk solids and nonfat solids is shown in Table 1.1.

Table 1.1. Proximate composition of whole milk solids and skim milk solids.

|

| Fat, % | 29.36 | 1.08 |

| Protein, casein, % | 22.22 | 31.18 |

| Whey protein, % | 4.76 | 7.53 |

| Lactose, % | 38.10 | 52.15 |

| Ash (minerals), % | 5.56 | 8.06 |

Accordingly, incorporation of dairy ingredients in a food adds these constituents to the overall food composition and allows a food developer to leverage their functionality and other attributes in food product development. Chemical, physical, and functional properties of milk are discussed in Chapter 2.

Variations in Milk Composition

It is important to recognize that milk composition varies depending on the breed of the cow, intervals and stages of milking, different quarters of udder, lactation period, season, feed, nutritional level, environmental temperature, health status, age, weather, estrus cycle, gestation period, and exercise (Chandan, 2007a; Kailasapathy, 2008). The variations in major constituents of milk, namely fat, protein, lactose, and minerals, are more noticeable in milk from individual cows. In general, these variations tend to average out and display an interesting pattern in commercial milk used by processors. Nevertheless, the seasonal variations in major milk constituents still impact important properties of finished products. In the United States, approximately 10% variation in fat and protein is observed in milk received in July and August (lowest level) as compared to milk delivered in October and November (highest level). Subsequently, the functional contribution of milk proteins (viscosity in yogurt and buttermilk, and curd firmness in cheese manufacture) follows a similar trend. Butter produced in summer is generally softer than that produced from winter milk. Furthermore, cheese yield and whey protein production can be negatively affected by seasonal variations in milk composition.

The concentration of minerals such as chloride; phosphates; and citrates of potassium, sodium, calcium, and magnesium in milk is important in processing, nutritive value, and shelf life of dairy products. Their concentration is less than 1% in milk. Still, they affect heat stability of milk, age-thickening of sweetened condensed milk, feathering of coffee cream, rennin coagulation, and clumping of fat globules on homogenization. All of the minerals considered essential for human nutrition are found in milk (Chandan, 2008d). For nutritive and health attributes of dairy ingredients, see Chapter 16.

Important Quality Factors

From a consumer standpoint, the quality factors associated with milk are appearance, color, aroma, flavor, and mouth feel. The color of milk is perceived by the consumer to be indicative of purity and richness. The white color of milk is due to the scattering of reflected light by the inherent ultramicroscopic particles, namely fat globules, colloidal casein micelles, and calcium phosphate. The intensity of white color is directly proportional to the size and number of particles in suspension. Homogenization significantly increases the surface area of fat globules as a result of breakup of larger globules. Accordingly, homogenized milk and cream appear whiter than non-homogenized counterparts. After the precipitation of casein and fat by the addition of a dilute acid or rennet, whey separates out. The whey possesses a green-yellow color due to the pigment riboflavin. The depth of color varies with the amount of fat remaining in the whey. Lack of fat globules gives skim milk a blue tinge. Physiological disturbances in the cow also make the milk bluer.

Cow’s milk contains the pigments carotene and xanthophylls, which tend to impart golden yellow color to the milk. Guernsey and Jersey breeds produce especially golden yellow milk. Milk from goats, sheep, and water buffalo tends to be much whiter in color because their milk lacks the pigments.

The flavor of milk is critical to its consumer quality criterion. Flavor is an organoleptic property in which both odor and taste interact. The sweet taste of lactose is balanced against the salty taste of chloride, and both are somewhat moderated by proteins. This balance is maintained over a fairly wide range of milk composition, even when the chloride ion varies from 0.06% to 0.12%. Saltiness can be organoleptically detected in samples containing chloride ions exceeding 0.12% and it becomes marked in samples containing 0.15%. The characteristic rich flavor of dairy products may be attributed to the lactones, methyl ketones, certain aldehydes, dimethyl sulfide, and certain short-chain fatty acids. As lactation advances, lactose declines while chlorides increase, so that the balance is slanted toward “salty.” A similar dislocation is caused by mastitis and other udder disturbances. Accordingly, milk flavor is related to its lactose : chloride ratio.

Freshly drawn milk from any mammal possesses a faint odor of a natural scent peculiar to the animal. This is particularly true for the goat, mare, and cow. The cow odor of cows’ milk is variable, depending upon the individual season of the year and the hygienic conditions of milking. A strong “cowy” odor frequently observed during the winter months may be due to the entry of acetone bodies into milk from the blood of cows suffering from ketosis.

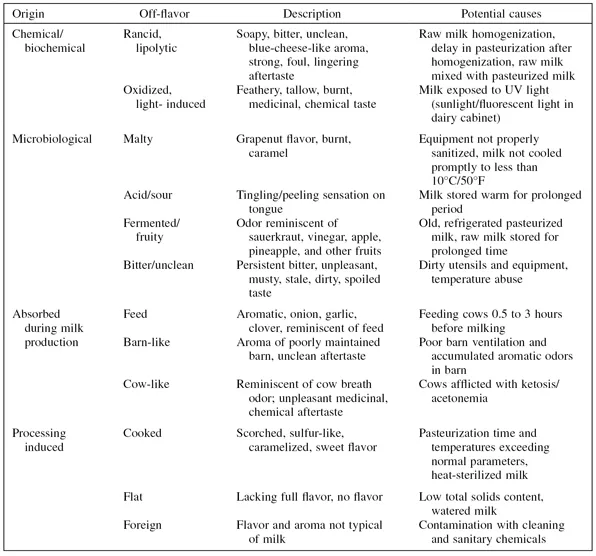

Feed flavors in milk originate from feed aromas in the barn; for instance, aroma of silage. In addition, some feed flavors are imparted directly on their ingestion by the animal. Plants containing essential oils impart the flavor of the volatile constituent to the milk. Garlic odor and flavor in milk is detected just one minute after feeding garlic. Weed flavor of chamomile or mayweed arises from the consumption of the weed in mixtures of ryegrass and clover. Cows on fresh pasture give milk with a less well-defined “grassy” flavor, due to coumarin in the grass. A “clovery” flavor is observed when fed on clover pasture, and these taints are not perceptible when dried material is fed. Prolonged ultraviolet radiation and oxidative taints lead to “mealiness,” “oiliness,” “tallowiness,” or “cappy” odor. Traces of copper (3 ppm) exert development of metallic/oxidized taints in milk. Microbial growth in milk leads to off-flavors such as sour, bitter, and rancid. Raw milk received at the plant should not exhibit any off-flavors. Certain minor volatile flavor may volatilized off by dairy processing procedures. Various off-flavors and their origins are summarized in Table 1.2.

Table 1.2. Origins and causes of off-flavors in milk and dairy ingredients.

Adapted from Chandan (1997, 2007a)

Raw Milk Quality Specifications

It is essential to set up stringent specifications for quality maintenance for purchasing milk, The specifications involve several parameters as discussed below.

Standard plate count (SPC) is a measure of the total bacteria count, and measures the overall microbiological quality of milk. High SPC can cause reduced shelf life of the finished product and off flavors from enzyme activity and elevated acidity.

Per Pasteurized Milk Ordinance (USDHHS PMO, 2003), the U.S. Federal Grade A Standards allow a maximum of 100,000 CFU/ml for an individual producer and 300,000 CFU in commingled milk. However, some states differ. For example, for an individual producer, the Idaho standard is 80,000 CFU/ml maximum and the California standard is 50,000 CFU/ml maximum. It is recommended to set the standard at 50,000 CFU/ml.

Coliform bacteria count is a measure of milk sanitation. High coliform counts reflect poor milking practices and unsatisfactory cleanliness of the dairy operation. Occasionally, coliform count may indicate sick cows in smaller herds. Coliform count is an indicator that food poisoning organisms may be present. There are no federal standards for coliform counts in raw milk, but California has a standard for coliform (750 CFU/ml maximum). A recommended standard is 500 CFU/ml.

Laboratory pasteurized count (LPC) is a measure of heat-stable bacteria that may survive pasteurization. It is performed by heat-treating laboratory samples to simulate batch pasteurization at 62.8°C (145°F) for 30 minutes and enumerating the bacteria that survive using the SPC method. High LPC results indicate potential contamination from soil and dirty equipment at th...