eBook - ePub

Pumps for Chemical Processing

J.T. McGuire

This is a test

Compartir libro

- 304 páginas

- English

- ePUB (apto para móviles)

- Disponible en iOS y Android

eBook - ePub

Pumps for Chemical Processing

J.T. McGuire

Detalles del libro

Vista previa del libro

Índice

Citas

Información del libro

A reference for the chemical engineer on the application, selection, construction, procurement, installation, operation, and maintenance of the three basic types of pumps used in chemical processing: centrifugal, rotary, and reciprocating. Emphasizes aspects that cause practical operating problems,

Preguntas frecuentes

¿Cómo cancelo mi suscripción?

¿Cómo descargo los libros?

Por el momento, todos nuestros libros ePub adaptables a dispositivos móviles se pueden descargar a través de la aplicación. La mayor parte de nuestros PDF también se puede descargar y ya estamos trabajando para que el resto también sea descargable. Obtén más información aquí.

¿En qué se diferencian los planes de precios?

Ambos planes te permiten acceder por completo a la biblioteca y a todas las funciones de Perlego. Las únicas diferencias son el precio y el período de suscripción: con el plan anual ahorrarás en torno a un 30 % en comparación con 12 meses de un plan mensual.

¿Qué es Perlego?

Somos un servicio de suscripción de libros de texto en línea que te permite acceder a toda una biblioteca en línea por menos de lo que cuesta un libro al mes. Con más de un millón de libros sobre más de 1000 categorías, ¡tenemos todo lo que necesitas! Obtén más información aquí.

¿Perlego ofrece la función de texto a voz?

Busca el símbolo de lectura en voz alta en tu próximo libro para ver si puedes escucharlo. La herramienta de lectura en voz alta lee el texto en voz alta por ti, resaltando el texto a medida que se lee. Puedes pausarla, acelerarla y ralentizarla. Obtén más información aquí.

¿Es Pumps for Chemical Processing un PDF/ePUB en línea?

Sí, puedes acceder a Pumps for Chemical Processing de J.T. McGuire en formato PDF o ePUB, así como a otros libros populares de Ciencias físicas y Química. Tenemos más de un millón de libros disponibles en nuestro catálogo para que explores.

Información

1. Introduction

Pumping in the chemical process industry involves the bulk movement of process liquids, the precise injection of reactants, and the provision and dissipation of energy. For convenience, these three functions are referred to as process, metering, and utility. While utility does not involve the handling of process chemicals, there will be no processing without it, so its inclusion is justified.

Pumping is the so-called “heart” of chemical processing, and it’s a good analogy. Successful pumping is thus of fundamental importance; achieving it involves getting all the following “right”:

- Conditions of service

- Pumping specification

- Procurement

- Installation

- Operation

- Maintenance

Not getting any one of these “right” can cripple a process. Generally, though, mistakes in the last four can be corrected, albeit at great expense. But if the first two are not “right,” if the basics are not sound, all subsequent corrections will be “Band-Aids.”

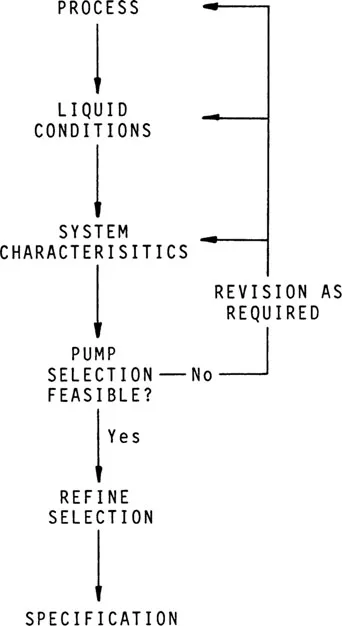

Because developing a sound pump specification is so important, it is the focus of this section. Figure 1.1 shows the basic sequence for doing this, which this volume follows. Note, also, that iteration is an inherent part of this sequence.

G 1.1. Process for developing a sound pump specification.

The pump types reviewed are centrifugal, rotary, and reciprocating. For each type the review covers basic characteristics, specific configurations and their uses, then available materials of construction, all with a view to chemical process service. For clarity, specific information on metering and utility pumps is given in Chapters 9 and 10, respectively.

The size of this volume is limited, thus an exhaustive treatment is not possible. Instead, the material seeks to highlight the fundamental, the novel, and the usually troublesome, thereby supplementing other related material. For greater detail on pumps in general, the reader is referred to the Pump Handbook [1.1], The Chemical Engineering Guide to Pumps [1.2], Centrifugal Pumps [1.3], and Reciprocating Pumps [1.4]. A recent publication, Process Pump Selection—A Systems Approach [1.5], adds notably to the “art” of pump selection (in metric units). Throughout the volume, references on specific topics are cited to enable further reading.

References

- 1.1. I. J. Karassik et al. (eds.), Pump Handbook, 2nd ed., McGraw-Hill, New York, 1986.

- 1.2. K. McLaughton (ed.), The Chemical Engineering Guide to Pumps, McGraw-Hill, New York, 1984.

- 1.3. I. J. Karassik and R. Carter, Centrifugal Pumps, McGraw-Hill, New York, 1960.

- 1.4. T. L. Henshaw, Reciprocating Pumps, Van Nostrand Reinhold, New York, 1987.

- 1.5. J. Davidson (ed.), Process Pump Selection—A Systems Approach, The Institution of Mechanical Engineers, Suffolk, U.K., 1986.

2. Liquid Conditions

Chemical process pumping involves the handling of liquids that are corrosive or toxic or both. This requirement distinguishes the service from general pumping and has a major bearing on materials of construction, internal mechanical construction, and the type of seal necessary.

Because the nature of the liquid to be pumped has such a bearing on pump construction, its precise determination is an essential first step in any pumping application. Not doing this with sufficient precision is a prime cause of premature failure in chemical pumps.

2.1. Properties

Liquid properties influence the type of pump and its mechanical construction. Those needed for pump selection are:

Specific gravity (SG) or relative density (RD)Vapor pressureViscosityRheological characteristic (if other than Newtonian)

Specific heat, though not often quoted, is useful, particularly when the application has minimal net positive section head (NPSH) available.

Liquid properties are usually specified at the pumping temperature or over the expected temperature range, if that is the case.

2.2. Temperature

Liquid properties and corrosiveness vary markedly with temperature, thus the precise temperature is important. General terms such as “cold,” “hot,” or “ambient” do not provide sufficient information. An ideal specification gives the expected temperature range and the normal operating temperature.

2.3. Constituents

Most liquids pumped are solutions of multiple constituents. To help insure the most appropriate materials are used for the pump, it is necessary to know the liquid’s constituents and their concentration. In this connection it is vital that all constituents, major and trace, be identified and that their concentration be given in specific units.

Trace constituents, particularly halogens, halides, or compounds of hydrogen, can render a nominally suitable material entirely unsuitable. Examples are the effect of fluorides on high silicon iron (cited by Birk and Peacock in Ref. 1.1) and of hydrogen sulfide on a variety of materials (see NACE [2.1]).

Concentration needs to be stated specifically to avoid varying interpretations of terms such as “dilute” and “concentrated.” Similar treatment is necessary for trace constituents because their effect can vary markedly with very small changes in concentration.

2.4. Acidity and Alkalinity

Whether a solution is acidic or alkaline or likely to vary is of consequence to material selection. For this reason, the solution’s pH, or possible range of pH, needs to be specified.

2.5. Aeration

The degree of aeration of a solution can have a significant effect on its corrosiveness. Alloys that rely upon oxidation for passivity, Type 316 stainless steel for example, suffer severe corrosion in deaerated solutions. For alloys dependent upon a reducing environment for corrosion resistance, aeration of the solution can promote severe corrosion.

2.6. Solids

In low concentrations, often seemingly innocuous, solids suspended in the pumped liquid can cause corrosion-erosion. Frequently, the damage can be severe enough to result in premature, catastrophic failure of a pump’s casing. If solids are likely to be present, their material, size, and concentration need to be specified.

2.7. Allowable Leakage

Pollution, both atmospheric and ground, known carcinogenic effects, and high toxicity dictate that many of the liquids used in the chemical industry be allowed to leak at only very low rates or not at all. Low or zero leakage requires special consideration in the selection, design, and quality of the pump’s “pressure boundary.”

2.8. Product Quality

With some liquid...