eBook - ePub

Ultrafiltration for Bioprocessing

Herb Lutz

This is a test

Compartir libro

- 244 páginas

- English

- ePUB (apto para móviles)

- Disponible en iOS y Android

eBook - ePub

Ultrafiltration for Bioprocessing

Herb Lutz

Detalles del libro

Vista previa del libro

Índice

Citas

Información del libro

Ultrafiltration for Bioprocessing is key reading for all those involved in the biotechnology and biopharmaceutical areas. Written by a leading worker in the area, it includes many practical applications and case studies in the key process of ultrafiltration (UF), which is used in almost every bioprocess.

- Focuses on ultrafiltration for biopharmaceuticals—other books look at general ultrafiltration or general biopharmaceuticals

- A mix of theory and practical applications—other books tend to be more theory-oriented

- Addresses the main issues encountered in development and scale-up through recommendations and case studies

Preguntas frecuentes

¿Cómo cancelo mi suscripción?

¿Cómo descargo los libros?

Por el momento, todos nuestros libros ePub adaptables a dispositivos móviles se pueden descargar a través de la aplicación. La mayor parte de nuestros PDF también se puede descargar y ya estamos trabajando para que el resto también sea descargable. Obtén más información aquí.

¿En qué se diferencian los planes de precios?

Ambos planes te permiten acceder por completo a la biblioteca y a todas las funciones de Perlego. Las únicas diferencias son el precio y el período de suscripción: con el plan anual ahorrarás en torno a un 30 % en comparación con 12 meses de un plan mensual.

¿Qué es Perlego?

Somos un servicio de suscripción de libros de texto en línea que te permite acceder a toda una biblioteca en línea por menos de lo que cuesta un libro al mes. Con más de un millón de libros sobre más de 1000 categorías, ¡tenemos todo lo que necesitas! Obtén más información aquí.

¿Perlego ofrece la función de texto a voz?

Busca el símbolo de lectura en voz alta en tu próximo libro para ver si puedes escucharlo. La herramienta de lectura en voz alta lee el texto en voz alta por ti, resaltando el texto a medida que se lee. Puedes pausarla, acelerarla y ralentizarla. Obtén más información aquí.

¿Es Ultrafiltration for Bioprocessing un PDF/ePUB en línea?

Sí, puedes acceder a Ultrafiltration for Bioprocessing de Herb Lutz en formato PDF o ePUB, así como a otros libros populares de Naturwissenschaften y Analytische Chemie. Tenemos más de un millón de libros disponibles en nuestro catálogo para que explores.

Información

Categoría

NaturwissenschaftenCategoría

Analytische Chemie1

Fundamentals

Herb Lutz EMD Millipore, Biomanufacturing Sciences Network

Abstract

This chapter provides a high-level overview of ultrafiltration. This includes basic terminology, principles of operation, performance characteristics, and applications where it is used. It is intended to provide an overall perspective and furnish a background to enable the reader to more readily understand the subsequent in-depth chapters.

Keywords

cross-flow filtration

filtrate

flux

formulation

NFF

permeate

retentate

tangential flow filtration

TFF

TMP

ultrafiltration

UF applications

UF membrane

UF operation

UF processing steps

UF system

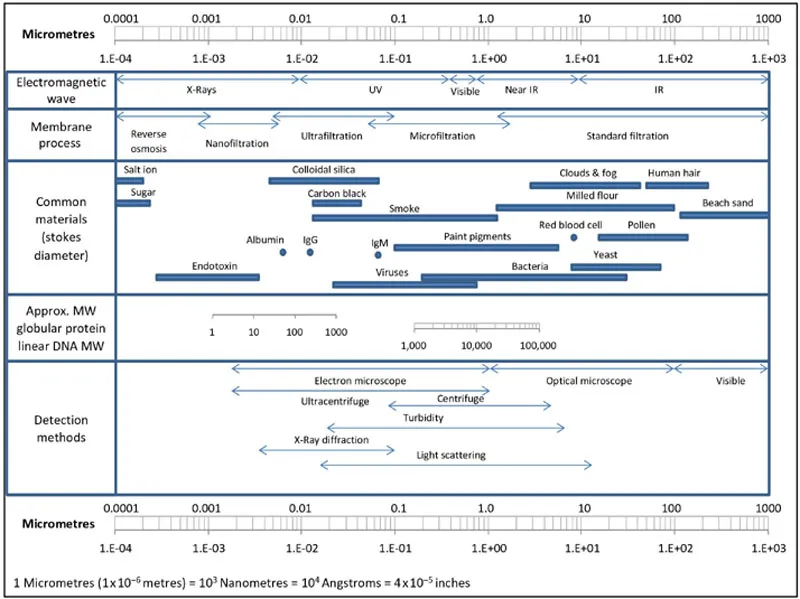

1.1. Membrane pore sizes

A membrane can be idealized as a film that readily passes solvents and small solutes but retains large solutes above a particular size. UF (Ultrafiltration) membranes retain solutes with hydraulic diameters in the 5–150 nm range. This roughly corresponds to molecular weights in the 1–1000 kDa range covering most proteins, nucleic acids, nanoparticles, viruses, and some polymers. In the field of membranes, the term nanofiltration refers to membranes tighter than ultrafiltration but more open than reverse osmosis (Figure 1.1). However, in biotechnology, it has come to refer to virus-retaining membranes that fall in the open ultrafiltration (roughly 100 kDa) to tight microfiltration range (roughly 0.1 μm).

Figure 1.1 Ultrafiltration size range.

1.2. Applications

In a biopharmaceutical manufacturing process, biopharmaceutical products are expressed in a bioreactor (for mammalian cells) or fermentor (for bacterial or yeast cells). Ultrafiltration has been used to retain colloids and cell debris while passing the expressed product. In a similar way, ultrafiltration has been used after a refold pool to retain refold aggregates while passing the refolded product. Following clarification, ultrafiltration has been used to remove the largest contaminant – water – by retaining the product in a concentration step. This can be to reduce the size of subsequent steps, which may have to be sized based on the batch volume rather than on product mass. In addition, volume reduction facilitates transport and storage. This can provide flexibility to a manufacturing operation by decoupling the upstream from downstream operations.

Ultrafiltration is used to purify large solutes, such as vaccines, by retaining the desired product and passing through unwanted smaller components. This can include passing unreacted PEG or unconjugated polymers. Ultrafiltration is also used to retain unwanted viruses or aggregates while letting the desired product pass through. When the desired product and unwanted solutes are close in size, this is a challenging fractionation operation. This book will not cover virus ultrafiltration, or nanofiltration as it is frequently called.

The most common application is the use of ultrafiltration for final product formulation. This involves retaining the product while concentrating it to the desired target, and conducting a buffer exchange using a diafiltration process. Small contaminants and the old buffer components pass through the membrane.

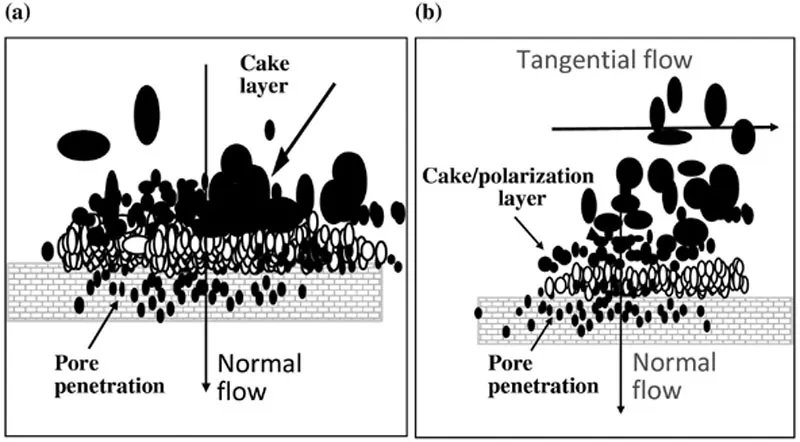

1.3. Modes of operation

Membranes are encased in modules for ease-of-operation. One could run the membrane in a static or dialysis mode where small buffer solutes can be exchanged by diffusion across the membrane (Figure 1.2). This is convenient at the bench scale but economical commercial operation requires bulk flow. UF can also be run in NFF (normal flow filtration) or TFF (tangential flow filtration) modes. NFF (Figure 1.2a) is the most common type of filtration. NFF mode involves passing the solvent through the filter under pressure where the fluid velocity is perpendicular (or normal) to the plane of the membrane. As the fluid passes through the membrane, it drags solutes with it to the membrane surface where they accumulate and cause the filter hydraulic resistance to increase. For high concentrations of retained solutes, NFF operation leads to relatively rapid plugging and low filter capacities. NFF is used at bench scale where low capacities pose less of a concern and the ease-of-use is convenient. NFF is also used for virus filtration.

Figure 1.2 Operating modes.

TFF mode (Figure 1.2b) involves adding another fluid velocity component parallel to the plane of the membrane so the net solvent flow strikes the membrane at an angle. The presence of the tangential flow at the membrane surface facilitates backflow of solutes and prevents filter plugging. While there remains a region of high solute concentration at the membrane surface, steady-state operation is reached and TFF operation shows very high filter cap...