eBook - ePub

Chemical Projects Scale Up

How to go from Laboratory to Commercial

Joe M. Bonem

This is a test

Compartir libro

- 232 páginas

- English

- ePUB (apto para móviles)

- Disponible en iOS y Android

eBook - ePub

Chemical Projects Scale Up

How to go from Laboratory to Commercial

Joe M. Bonem

Detalles del libro

Vista previa del libro

Índice

Citas

Información del libro

Chemical Projects Scale Up: How to Go from Laboratory to Commercial covers the chemical engineering steps necessary for taking a laboratory development into the commercial world. The book includes the problems associated with scale up, equipment sizing considerations, thermal characteristics associated with scale up, safety areas to consider, recycling considerations, operability reviews and economic viability. In addition to the process design aspects of commercializing the laboratory development, consideration is given to the utilization of a development in an existing plant.

- Explains how heat removal for exothermic reactions can be scaled up

- Outlines how a reactor can be sized from batch kinetic data

- Discusses how the plant performance of a new catalyst can be evaluated

- Presents how the economics of a new product/process can be developed

- Discusses the necessary evaluation of recycling in commercial plants

Preguntas frecuentes

¿Cómo cancelo mi suscripción?

¿Cómo descargo los libros?

Por el momento, todos nuestros libros ePub adaptables a dispositivos móviles se pueden descargar a través de la aplicación. La mayor parte de nuestros PDF también se puede descargar y ya estamos trabajando para que el resto también sea descargable. Obtén más información aquí.

¿En qué se diferencian los planes de precios?

Ambos planes te permiten acceder por completo a la biblioteca y a todas las funciones de Perlego. Las únicas diferencias son el precio y el período de suscripción: con el plan anual ahorrarás en torno a un 30 % en comparación con 12 meses de un plan mensual.

¿Qué es Perlego?

Somos un servicio de suscripción de libros de texto en línea que te permite acceder a toda una biblioteca en línea por menos de lo que cuesta un libro al mes. Con más de un millón de libros sobre más de 1000 categorías, ¡tenemos todo lo que necesitas! Obtén más información aquí.

¿Perlego ofrece la función de texto a voz?

Busca el símbolo de lectura en voz alta en tu próximo libro para ver si puedes escucharlo. La herramienta de lectura en voz alta lee el texto en voz alta por ti, resaltando el texto a medida que se lee. Puedes pausarla, acelerarla y ralentizarla. Obtén más información aquí.

¿Es Chemical Projects Scale Up un PDF/ePUB en línea?

Sí, puedes acceder a Chemical Projects Scale Up de Joe M. Bonem en formato PDF o ePUB, así como a otros libros populares de Technik & Maschinenbau y Chemie- & Biochemietechnik. Tenemos más de un millón de libros disponibles en nuestro catálogo para que explores.

Información

Categoría

Technik & MaschinenbauCategoría

Chemie- & Biochemietechnik1

Potential Problems With Scale-up

Abstract

A crafty operations manager once told a conference room full of new engineers—“If over the years, we had saved one half the amount of money that the projects engineered by people like you claimed to save, the company would be a lot better off financially.” Although not all the projects that he had in mind were scaled up from the results obtained from the laboratory or pilot plant, several of them were. This cynical statement illustrates that all scale-ups do not go as planned or forecasted. If this is true, then any book on scale-up must provide answers to the question as to what happened or why was the scale-up not successful. There are several reasons why scale-ups fail.

Keywords

completeness of pilot plant

computational fluid dynamics

driving force

equipment

safety

thermal considerations

study designs

A crafty operations manager once told a conference room full of new engineers—“If over the years, we had saved one half the amount of money that the projects engineered by people like you claimed to save, the company would be a lot better off financially.” Although not all the projects that he had in mind were scaled up from the results obtained from the laboratory or pilot plant, several of them were. This cynical statement illustrates that all scale-ups do not go as planned or forecasted. If this is true, then any book on scale-up must provide answers to the question as to what happened or why was the scale-up not successful. There are several reasons why scale-ups fail. These reasons were mentioned in the introduction and can be summarized as follows:

- • Equipment Related—Scale-up will always involve larger equipment and possibly a change in equipment design such as a jacketed vessel to a pump-around exchanger loop.

- • Mode Related—A typical scale-up may well involve a change in equipment mode such as a change from a batch reactor to a continuous reactor.

- • Theoretical Considerations—Although theoretical conclusions and considerations have generally been the regime of the laboratory chemists, the scale-up should consider if it is possible that anything is missed or erroneous conclusions have been drawn.

- • Thermal Characteristics—Scale-up of a reactor or any other vessel where heat transfer is occurring will always require consideration due to the potentially reduced area-to-volume ratio.

- • Safety Considerations—Although safety is always a consideration, it is more so as the equipment size is increased.

- • Recycle Considerations—Several factors require that recycle facilities be included in commercial facilities, although it may not be as important in laboratory or pilot plant facilities.

- • Regulatory Requirements—Regulation might include products, process, and by-product disposal.

- • Project Focus Considerations—The project team must maintain focus on the development and the economic aspects of the process.

Now considering these eight general causes of scale-up failure, the next few paragraphs add detail to the aforementioned summary.

Equipment Related

Determining the equipment size often involves a change in the type of equipment. For example, bench-scale work is often conducted as a batch process, wherein each reactant has the same amount of residence time. However, in a commercial design, it is almost always desirable to have a continuous flow reactor. This type of reactor is often a stirred reactor and is simulated as a perfectly mixed vessel. In this case, some of the reactants leave the reactor almost instantly and some remain in the reactor for a time much greater than the average residence time. This factor by itself will increase the residence time requirements in the commercial plant relative to the bench scale.

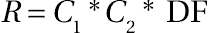

Whether equipment is of the same type or not, the results from a laboratory or a pilot plant can generally be scaled up by making judicious use of the following generalized Eq. (1.1):

- where

- R = The kinetic rate of the process.

- C1 = A constant determined in the laboratory, pilot plant, or a smaller commercial plant. Generally, this constant will not change as the process is scaled up to the larger rate.

- C2 = A constant that is related to the equipment’s physical attributes such as area, volume, L/D ratio, mixer speed, mixer design, exchanger design, or any other physical attribute. This constant will be a strong function of the scale-up ratio. As discussed later, it is not always identical to the scale-up ratio.

- DF = The driving force that relates to a difference between an equilibrium value and an actual value. This might be temperature driving force, reactant concentration driving force, or volatiles concentration driving force. The driving force will always have the form of the actual value minus an equilibrium value.

The process described by Eq. (1.1) could be heat transfer, volatile stripping, reaction, or any process step wherein equilibrium is not reached instantaneously. The kinetic rate is usually expressed in terms of the value of interest (conversion, heat transfer, or volatiles concentration) per unit time. If the required rate is expressed in absolute units (for example, BTU/h), it will be much lower in the laboratory or a pilot plant than what it is in the commercial plant. As defined earlier, the ratio of the rate in the commercial plant to that in the smaller plant is the scale-up ratio.

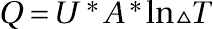

Although this Eq. (1.1) might be considered a simplification of the complexity of scale-up, it illustrates the basic criteria that must be considered. The following well-known simplified heat transfer equation (shown below) is a form of this generalized Eq. (1.1):

- where

- Q = The kinetic rate or, in the case of heat transfer, it is the rate of heat removal/addition expressed in heat units (BTU or calories) per unit time (normally hours).

- U = The constant comparable to C1 or, in this case, the heat transfer coefficient.

- A = The heat transfer area, which is the constant comparable to C2.

- ln∆T = The temperature driving force or, in this case, the “log delta T.”

The use of Eq. (1.1) allows consideration of the various aspects of equipment-related scale-up from several angles. This concept is explained in greater detail in Chapter 2. When considering this concept as defined by Eq. (1.1), several questions need to be considered. The overriding question is always, what is the scale-up ratio. It can be defined in multiple ways—production rate, heat removal rate, volatile removal rate, etc.

It should be noted that the scale-up ratio is always defined using a time element. Some of the other questions that need to be considered are as follows:

- • What is the required ratio of the kinetic value R? This maybe the ratio of the production rates between the smaller facilities and the larger facility. However, when considering the example of a heat exchanger, the ratio of heat exchanged (Q) may be more or less than the production rate ratio, because the inlet and outlet temperatures may be different in a commercial unit than a bench scale or a pilot plant. Another possibility to be considered is a jacketed reactor with a pump-around cooling loop. In such a scenario, due to the reduced area-to-volume ratio (A/V) in the jacketed reactor of the larger unit, the actual Q on the external pump-around heat exchanger maybe higher than that which would be calculated by a direct ratio of total heat exchanged in the two reactors. The key concept is that the actual scale-up should be based on the unit operation of interest rather than a simple ratio of production rates.

- • Is it really reasonable to assume that C1 does not change between the smaller and larger facility? Generally, the answer is that this is a reasonable assumption. However, when considering problems with scale-up, this is an area that must be considered. A real-life example of the change of C1 was a vertical heat exchanger in a commercial plant being used to condense propylene. This exchanger was scaled up to a higher capacity while maintaining C1 (the heat transfer coefficient, U) constant at the value demonstrated in the smaller facility. During ...